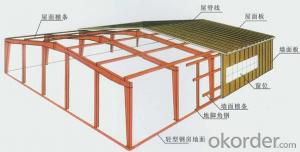

Polyurethane Foam Sandwich Panel for Wall Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

polyurethane sandwich panel

the bothside metal sheet thick is 0.4mm to 0.6mm

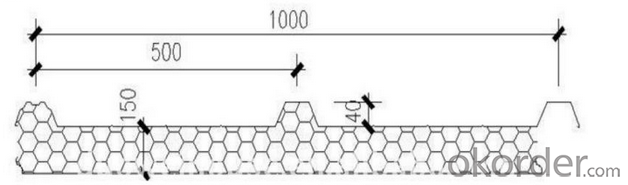

width is 1000mm .

thickness have 50 75 100mm

The white metal sheet coated wall pu sandwich panel

1.0.4-0.6mm steel sheet

2.light weight

3.density 40-42 kg/m3

4.fire rating

5.Fire rating,waterproof,weather proof, anticorrosion

6.Top and bottom sheet's thickness:0.25-0.6mm

7.Panel's thickness:50-200mm

8.Appliance:Farm,chicken shed

9. Easy-installation

Technical parameters

Commodity | pu sandwich panel |

Effective width | Wall panel: 1000mm Roof panel: 1000mm

|

Unfolding width |

1200mm 1000mm |

Length/piece |

As customer' s request, less than 11.8m for transportation |

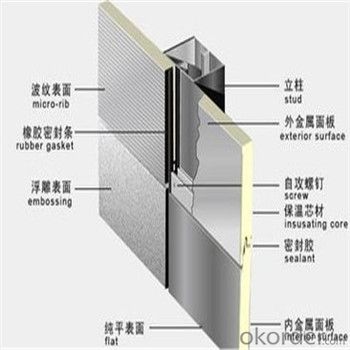

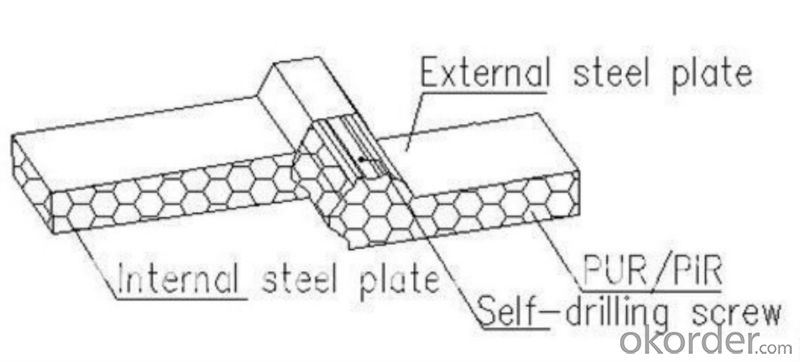

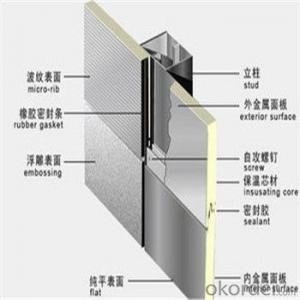

Structural material |

Steel sheet+PU+steel sheet Middle materials:polyurethane foam board(PU) Top and bottom: prepainted galvanized steel sheet

|

Thickness | steel sheet: 0.25-0.6mm

polystyrene foam: 50mm 75mm 100mm 150mm 200mm |

Density | PU 40-42kg/m3 |

Common color | Ocean blue, white grey,red,or as customer require |

Color coating | Top is 13 micron,bottom is 5 micron or as customer need |

Lifespan | More than 25 years |

Advantage | Light weight, heat insulation, water resistant, weatherproof,low cost,green and environmental |

Applance | Factory,warehouse,school,workshop, storages, exhibition halls, gymnasiums etc. |

Brand name | Yulong |

Delivery time | 7-15 days after receiving your deposite |

Payment term | T/T(30% by T/T in advance,balance against B/L copy) |

Expandable polystyrene sandwich panel factory

1.0.25-0.6mm steel sheet

2.light weight

3.density 7-25kg

4.fire rating

5.Fire rating,waterproof,weather proof, anticorrosion

6.Top and bottom sheet's thickness:0.25-0.6mm

7.Panel's thickness:50-200mm

8.Appliance:Farm,chicken shed

9. Easy-installation

FQA:

Can be changed the size of panel?

Yes, according to the design of the costumer.

What is the minimum production?

4000m2 x 1 day x 8hours.

- Q: Are sandwich panels suitable for automotive showrooms?

- Yes, sandwich panels are suitable for automotive showrooms. Sandwich panels are made up of two outer layers or skins with a lightweight core material in between, providing excellent strength and insulation properties. These panels are versatile and can be used for various applications, including building facades, partitions, and interior walls. In automotive showrooms, sandwich panels can be used for constructing walls, ceilings, and even floors. They offer several benefits that make them ideal for this environment. Firstly, sandwich panels provide excellent insulation, which helps maintain a comfortable temperature inside the showroom, regardless of the weather outside. This is crucial for creating a pleasant environment for both customers and staff. Additionally, sandwich panels are lightweight and easy to install, allowing for quick and efficient construction. This is beneficial for automotive showrooms, as they often have tight deadlines and need to be operational as soon as possible. The panels can be easily cut and shaped to fit specific design requirements, allowing for flexibility in creating unique and attractive showroom layouts. Sandwich panels also offer good noise reduction properties, ensuring a quieter environment within the showroom. This is important for providing a comfortable atmosphere for customers and allowing them to focus on the vehicles on display. Furthermore, sandwich panels are durable and require minimal maintenance. They are resistant to corrosion, moisture, and fire, ensuring a long-lasting and safe solution for automotive showrooms. Additionally, the outer layers of the panels can be customized with various finishes and colors, allowing for branding and aesthetic preferences to be incorporated into the showroom design. Overall, sandwich panels are a suitable choice for automotive showrooms due to their insulation properties, ease of installation, noise reduction capabilities, durability, and customization options. They provide a cost-effective and efficient solution for creating a functional and visually appealing environment to showcase vehicles.

- Q: 3 side of the wall surrounded by color steel ~ the other side of the water ~ Will the three sides of the gap with the wall how to waterproof ~ Question added: whether you can use the blowing agent, the top of the same thing (which tell me what) And then sealed with black glue. More

- I have a veteran to sell, because I just bought a new Taiwan, the price of ..

- Q: Color steel sandwich panels and color steel plate What is the difference

- Color steel sandwich panels are divided into rock wool sandwich panels, foam sandwich panels, rock wool color steel sandwich panels

- Q: Color steel room life in general how many years

- Polystyrene board is too fragile with the general use of extruded plate ah to protect the membrane waterproof layer

- Q: Color steel sandwich board on the price of how much?

- Surface leveling should be able to, but the words come back, multilayer is cheaper than the former! For more information, better advice, free of charge to provide concrete waterproof water leakage II Cao Hao 丨 sell Zhatai Chunjun repair professional and technical advice, from today's repair, tomorrow leak;

- Q: The general company to re-change the new version, the replacement is very troublesome. Our company's exterior wall decoration board convenient installation, thermal insulation, waterproof moisture, noise reduction noise are interested can consult. Polyurethane sandwich panels for the application of polyurethane sandwich panels

- First of all, the tempered glass can no longer be drilled high and the ancient antecedant for the short hole, will certainly be broken, and do not make the edge of the local force, but also fragile (so use a few bumps to block it The method is not good) should be tempered glass as a whole embedded in a slot, you can in the low side of the welding of a corner, the length of the glass and the same edge, play a block of the role, in addition, usually the tempered glass is not easy to be deformed Damage, but can not make it too much force

- Q: Sandwich board is the two sides are metal, the middle of the building materials is the problem of foam added: What is the use of more adhesive

- According to material classification: can be divided into inorganic insulation materials, organic insulation materials and composite insulation materials three types. Inorganic insulation materials are common: YT inorganic reactive wall insulation materials, rock wool board, glass beads insulation mortar, foam cement board, glass wool board and so on. Organic insulation materials are: molded polystyrene board, extruded polystyrene board, phenolic resin board, polyurethane plate and so on. According to the shape classification: can also be divided into plate, powder and so on. According to the fire rating: divided into A-class non-flammable type, B1 grade flame retardant, B2 grade combustible type. Inorganic insulation materials are A-class materials, organic insulation materials up to B1 level.

- Q: Consult the requirements of the flame retardant 0 standard from which the standard standard, and then ask the next level 0 flame retardant standard self-extinguishing time is how much. More

- Clamp material, and pressure ah, a little bit of deformation of the clamp will lead to the next time the use of water leakage; some clamp is sealed with rubber ring, pressure, the rubber ring is not fully restored, will lead to Leakage of water; some cases in the pressure, the pipeline to the development of the process of training, but also lead to tight hoop tightly

- Q: What is the difference between rock wool sandwich panels, EPS sandwich panels and polyurethane sandwich panels?

- When the top of the ventilation tube can not be extended out of the roof, the following ventilation can be used: ①, set the side wall ventilation tube ②, by setting the confluence of the ventilation pipe after the extension of the side wall to extend above the roof ③, set up self-circulation ventilation pipeline system , the following circumstances should be set up ventilation riser: ①, when the drainage pipe to take the sanitary equipment drainage design flow than in Table 449 only set the top of the drainage pipe drainage pipe maximum design drainage capacity ②, the building standards require a high multi-storey residential and public buildings, 10-storey and 10-storey high-rise building life drainage riser , the following drainage pipe should be set up annular ventilation pipe: ①, connecting four and more than four sanitary ware and the length of more than 12m of the drainage pipe ②, connecting 6 and 6 or more toilet toilet cross pipe ③, do not exceed the above provisions, but the nature of the building is important, the use of high requirements or set the device when the ventilation tube , the health, quiet requirements of the building, the living drainage pipe should be set to ventilator tube , the drainage pipe at all levels of the building shall be provided with an annular ventilation pipe, and shall be provided with a main ventilation riser or a secondary ventilation riser for the connection of the layers , ventilation riser shall not accept the equipment of sewage, waste water and rain; not connected with the duct and flue

- Q: What kind of manual sandwich panels can be done? What is the difference between a manual sandwich panel and a mechanism sandwich panel? More

- Pipe pressure deformation, pressure relief pipe is not restored, the clamp inside the leather pad is not restored, there may be water seepage

Send your message to us

Polyurethane Foam Sandwich Panel for Wall Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords