Polyethylene Sandwich Panels - PPGI, PPGL, GI, GL, CR, Corrugated Steel Sheet, Color Steel Lamination

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Vertical/Horizontal, full wrapped with anti-moist paper inside, iron sheet (sea worthy),with pallet |

| Delivery Detail: | 20-25 days after receiving the deposit |

Specifications

PPGI, PPGL , GI , GL, CR and Corrugated steel sheet

thickness : 0.12mm to 1.2mm,

width :600mm to 1500mm

zinc coat:30-275g

We can offer PPGI and GI in thickness available from 0.12mm to 1.2mm, width available from 600mm to 1500mm

Basic information

1: Size: 0.15-1.2mm*600-1250mm

2: Paint: Top side: 15-25um, Back side: 5-9um, or according to customer’s order.

3: Base material: Hot dipped galvanized steel coil, GL

4: Zinc coating: 30-275g.

5: Coil weight: 3-6tons

6: Coil ID: 508mm

7: Color: Any color.

8: Standard: ASTM, GB, JIS

9:Grade: CGCC,CGCH,SGCC, DX51D and ASTM

10:Surface Treatments: skin passed, chromated, oiled and antifinger

11: Approved Certificate: SGS / ISO9001 / BV

12: Package Method: Vertical/Horizontal, full wrapped with anti-moist paper inside, iron sheet (sea worthy)

13: Payments terms: T/T ,L/C,etc.

Brief Introductionof product

1. Color Coated steel Coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized steel sheets.

2. The base metals for Color Coated Steel Coil consist of cold rolled, HDG electro-galvanized and hot-dip alu-zinc coated steel. The finish coats of Color Coated Steel Coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the Color Coated Steel Coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The Color Coated Steel Coil can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

Mechanical Properties

1. Mechanical properties of base metals

Grade | Tensile Test | ||

Yield Strength MPa | Tensile Strength MPa | Elongation A80mm % ≥ | |

SGLCC | 140-350 | 270-500 | 22 |

SGLCD | 140-300 | 270-420 | 26 |

SGLCDD | 140-260 | 270-380 | 30 |

2. Common performance of front coating

(1). Thickness: ≥20μm

(2). Pencil Hardness: 2H

(3). 60° specular glossiness of coating: >60

(4). 180°bend: ≤3T

(5). Impact: ≥9J

(6). Salt Fog Resistant: ≥500h

(7). Color difference: <3ΔE

- Q: Are sandwich panels suitable for automotive showrooms?

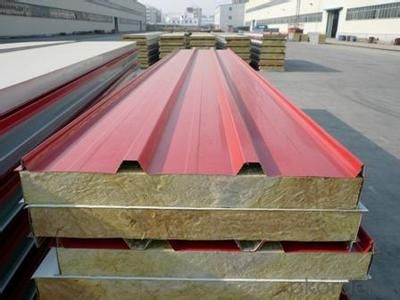

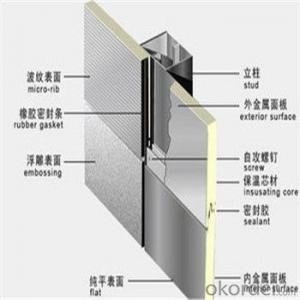

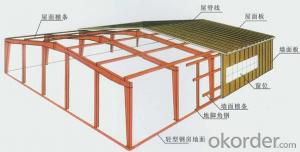

- Yes, sandwich panels are suitable for automotive showrooms. Sandwich panels are made up of two outer layers or skins with a lightweight core material in between, providing excellent strength and insulation properties. These panels are versatile and can be used for various applications, including building facades, partitions, and interior walls. In automotive showrooms, sandwich panels can be used for constructing walls, ceilings, and even floors. They offer several benefits that make them ideal for this environment. Firstly, sandwich panels provide excellent insulation, which helps maintain a comfortable temperature inside the showroom, regardless of the weather outside. This is crucial for creating a pleasant environment for both customers and staff. Additionally, sandwich panels are lightweight and easy to install, allowing for quick and efficient construction. This is beneficial for automotive showrooms, as they often have tight deadlines and need to be operational as soon as possible. The panels can be easily cut and shaped to fit specific design requirements, allowing for flexibility in creating unique and attractive showroom layouts. Sandwich panels also offer good noise reduction properties, ensuring a quieter environment within the showroom. This is important for providing a comfortable atmosphere for customers and allowing them to focus on the vehicles on display. Furthermore, sandwich panels are durable and require minimal maintenance. They are resistant to corrosion, moisture, and fire, ensuring a long-lasting and safe solution for automotive showrooms. Additionally, the outer layers of the panels can be customized with various finishes and colors, allowing for branding and aesthetic preferences to be incorporated into the showroom design. Overall, sandwich panels are a suitable choice for automotive showrooms due to their insulation properties, ease of installation, noise reduction capabilities, durability, and customization options. They provide a cost-effective and efficient solution for creating a functional and visually appealing environment to showcase vehicles.

- Q: 3 side of the wall surrounded by color steel ~ the other side of the water ~ Will the three sides of the gap with the wall how to waterproof ~ Question added: whether you can use the blowing agent, the top of the same thing (which tell me what) And then sealed with black glue. More

- The wall is relatively smooth, the external wall insulation per square meter with the mortar 4-foot often end of the shop to the whole shop 6 kg foot; wall is the wall, more mortar, a square need 7-9 kg

- Q: General color steel foam sandwich panels. How much a square is flat

- Plywood is made of three or more layers of 1mm thick veneer sheet made of hot pressing Plywood is generally divided into 3mm, 5mm, 9mm, 12mm, plywood buy plywood by multi-layer single The plates are arranged in a crisscross arrangement The outermost front panel is called a panel, and the back is called a backplane The inner board is called the core plate Ask the question? The They said that the use of the shoe cabinet, wardrobe with a sandwich panel answer:

- Q: Color steel room life in general how many years

- Safety information complete directory directory Chapter 1 construction site safety technical data management of the main content and requirements Section I construction site safety technical information management of the meaning of Section II of the construction site safety technology management system Section III construction site safety technology The establishment of the data Section IV of the construction site safety technical information classification The second chapter of the construction site safety management information Section I in progress construction safety supervision and related documents (the first file box) Section II safety production responsibility system (second file Box) Section III of the target management (the third file box) Section IV of the safe construction of the organization design (the fourth file box) Section V Division (sub-project) Safety Technology to the end of the (fifth file box) Section VI security check (The sixth file box) Section VII of the safety education (the seventh file box) Section VIII of the pre-class security activities (eighth file box) Section IX special operations certificates (ninth file box) Section X accident ( The eleventh section of the security box (the eleventh file box) Section XII security equipment and machinery and equipment related to the management of documents (tenth File box) Section XII mechanical equipment, facilities acceptance test records (thirteenth file box) Section XIV construction of temporary electricity (the fourteenth file box) Section fifteenth civilized construction (fifteenth file box) trade union Labor protection information

- Q: Own balcony capped, with the kind of sandwich panels better, EPS sandwich panels or rock wool sandwich panels, or other kind of sandwich panels?

- The greater the density. Strength is higher. But the thermal conductivity is the lower However, I do squeeze nail fan teeth both hands and pay only try to dig a thin plate of this line a little bit of time it is recommended that you still choose the high density of the thermal conductivity will be low, not much lower. Just some of the sales of the plate to the low density that means a good thing only.

- Q: How the exterior of the house is made of rock wool color steel sandwich panels

- Construction, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, Erecting outside the scaffolding materials expected ribs of the late section of the dwarf light dog chupu count, template support frame, shelf safety operation technology. Zibu type construction fastener, by the two holes in the diameter of the child is significantly different, the female fastener riveting, two fasteners on the lower cover are steel stamping parts, cover, under the cover with ribs , The upper and lower cover of the middle part of the arc inward convex, the arc-shaped convex surface and the upper and lower cover on both sides of the same cylindrical surface, the child, the female fastener nut on the same size. The fastener is used to build construction scaffolding, building fence, planting greenhouses, etc., can be connected to different diameter pipe, can be rotated angle, wide range of applications, and the fastener weight, bending strength and good steel, , Easy to use.

- Q: 800 * 800 tiles can not stick to the sandwich panel on the wall to do

- Wall insulation is an important part of the work of home insulation, divided into external wall insulation and internal wall insulation two, the amount of internal wall insulation works much smaller than the external wall insulation, Xiaobian today to share the advantages and disadvantages of various interior wall insulation materials The Polystyrene foam board polystyrene foam board is one of the three common wall insulation materials

- Q: How does the wall rock wool sandwich panel be installed?

- will be fixed on the wall insulation material, play a warm and warm role in warm technology

- Q: Consult the requirements of the flame retardant 0 standard from which the standard standard, and then ask the next level 0 flame retardant standard self-extinguishing time is how much. More

- Steel pipe is a steel pipe bowl buckle is the connection point like a bowl button is the connection point is a disk above a lot of hole pin is not a national standard thing is not recommended to use

- Q: What is the difference between rock wool sandwich panels, EPS sandwich panels and polyurethane sandwich panels?

- When the top of the ventilation tube can not be extended out of the roof, the following ventilation can be used: ①, set the side wall ventilation tube ②, by setting the confluence of the ventilation pipe after the extension of the side wall to extend above the roof ③, set up self-circulation ventilation pipeline system , the following circumstances should be set up ventilation riser: ①, when the drainage pipe to take the sanitary equipment drainage design flow than in Table 449 only set the top of the drainage pipe drainage pipe maximum design drainage capacity ②, the building standards require a high multi-storey residential and public buildings, 10-storey and 10-storey high-rise building life drainage riser , the following drainage pipe should be set up annular ventilation pipe: ①, connecting four and more than four sanitary ware and the length of more than 12m of the drainage pipe ②, connecting 6 and 6 or more toilet toilet cross pipe ③, do not exceed the above provisions, but the nature of the building is important, the use of high requirements or set the device when the ventilation tube , the health, quiet requirements of the building, the living drainage pipe should be set to ventilator tube , the drainage pipe at all levels of the building shall be provided with an annular ventilation pipe, and shall be provided with a main ventilation riser or a secondary ventilation riser for the connection of the layers , ventilation riser shall not accept the equipment of sewage, waste water and rain; not connected with the duct and flue

Send your message to us

Polyethylene Sandwich Panels - PPGI, PPGL, GI, GL, CR, Corrugated Steel Sheet, Color Steel Lamination

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords