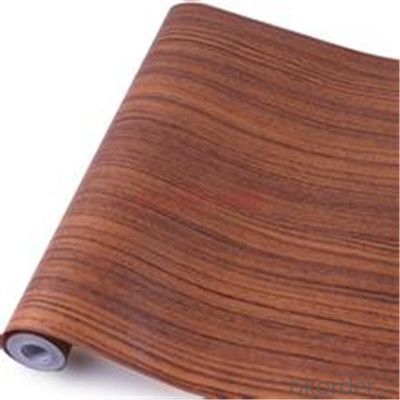

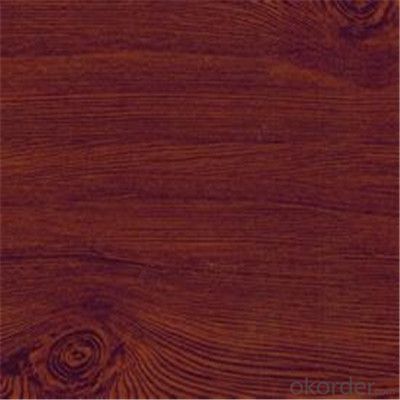

Wood Pattern Prim Galvanized PPGI Steel Sheet

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 99 m.t.

- Supply Capability:

- 1200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of Glove:

Grade : SGCD,SGCH, Q195,DX51D

Galvanized steel sheet /coil features:

1. Zinc coating :40-180g( as required)

2. thickness:0.2-1.2mm

3. width:914-1250mm(914mm, 1215mm,1250mm,1000mm the most common)

4. coil id:508mm/610mm

5. coil weight: 4-10 MT(as required)

6. surface: regular/mini/zero spangle, chromated, skin pass, dry etc.

Festures of Glove:

Standard | ASTM / JIS / BS / DIN / GB / AS |

Steel Grade | SGCC, SGCH, DX51D, SGH440, G250, G340, G450, G550 |

Base Material | Galvanized, Galvalume(Alu-zinc), Cold rolled steel |

Coating Material | PE / SMP / HDP / PVDF |

Top color coating | 15-45microns (any color of RAL) |

Back color coating | 5-15microns (off-white) |

Thickness | 0.14mm-1.50mm (TCT or BMT) |

Standard width | 914/1000/1200/1219/1250mm, or as required |

Coil weight | 3-5tons, or as required |

Coil I.D. | 508mm / 610mm |

Specifications of Glove:

High heat resistance: The reflective surface of the material aids in efficiently reflecting the sunlight away and in turn reducing the amount of heat transmitted. The thermal reflectivity converts into energy savings.

Images of Glove:

FAQ:

1.What about the delivery.

We can arrange the shipment about 15-25 days after the deposit.

2.What about payment term?

30% T/T deposit, balance against B/L copy.

Full T/T payment if quantity less than MOQ.

3.How much about MOQ?

Normally 100pcs,but small order is acceptable as well.

- Q: How are steel coils used in the production of agricultural systems?

- Steel coils are used in the production of agricultural systems as they are often shaped into various components like frames, supports, and structures. These components provide strength, durability, and stability to agricultural equipment such as tractors, harvesters, and irrigation systems, ensuring their long-term functionality and reliability in demanding farming environments.

- Q: Can steel coils be coated with silicon?

- Yes, steel coils can be coated with silicon.

- Q: What minerals are mixed to make steel?

- Carbon and Iron.....usually.

- Q: how is stainless steel made? what are the things used in making it?

- There are 3 basic stainless steels. The Martinsitic, the ferritic, and the Austinistic. The spelling may be wrong on all of them. (Got out of school in 1966 with my metallurgy in 1965. The Ferritic is magnetic and has some resistance to corrosion but the Martinsitic is much more resistant to corrosion. The Austinitic stainless is very resistant to corrosion. The differences are the amount of Chrome and Nickel in the batches. The Austinitic has an 18/8 ratio of Chromium and Nickel with the rest Iron and minor ingredients. The carbon content is very important and these steels are often made in small batches with close monitoring of composition and carbon content. Scrap metals are frequently used with the chrome and nickel being added as carefully selected scrap or even fresh crude stocks. Electric melting is frequent to avoid contamination.

- Q: How are steel coils used in the production of shelving units?

- Steel coils are used in the production of shelving units by being processed and formed into various components such as shelves, brackets, and support beams. These coils are typically cut, bent, and welded to create the necessary shapes and sizes required for the shelving unit. The steel material provides strength and durability to the shelves, ensuring they can hold heavy items and withstand the weight placed on them.

- Q: Would the Ruger Sr22 pistol or the SW MP 15-22 be any good for the steel challenge?

- I'd rather have the rifle myself.

- Q: How much should someone sell a 6 ft stainless steel counter? How about one with a sink?

- Sheet stainless steel is about $2.00 to $2.75 per lb. in the US right now for a 2B stainless steel without any special finish. The cost of a sink or counter is going to vary widely. The labor to fabricate it is going to be a lot higher than the material cost so the price per pound is not going to tell you much. In California a custom 6' counter would be somewhere between $1,200 and $3,000. A standard size single compartment sink would be about half of that.

- Q: I'm going to see Man Of Steel this weekend, and the reviews that I've been hearing aren't that good. I've been hearing that it's this depressing, dark, dramatic film with no humor, loud noises, and action on top of action (which is kind of what I expected from this movie). With that said, I was quite positive that this was what the fans wanted, a more serious Super Man interpretation. I'm ultimately going to judge the movie when I see it, but for now, I have 3 short questions for you:1) What did you think of Man Of Steel?2) Superman Returns got somewhat better reviews than Man Of Steel. Does it seem logical?3) There is a huge fan battle between Man Of Steel and Christopher Reeve's version of Super Man. Which one do you favor?

- saw it yesterday and it was great. all the complaints about it being gloomy...nonsense really. how would u feel if u found out ur life was a big question mark THEN u grow up only to get tossed in giant sh*t storm. many right now are excluding this is a story driven movie/character. u can't go in expecting anything with this movie especially ANY comparison to precious films. between Reeves and Cavill... I'm not gonna make that decision yet. this portrayal was one of a complete serious nature. u only get a couple glimpses of other emotions. the ending was a great lead off in which the sequel will showcase a lot more emotion within the character guaranteed. for now Reeves is still the best. until we all see Cavill display a full form of charm and charisma then the entire debate is really pointless

- Q: What is the material of steel coil 08F and what brand can be used instead?

- Characteristics and applicable range of 08F:Its strength is low, and the steel is soft, plastic and tough. General use does not require heat treatment, but in order to eliminate the internal force due to cold processing, improve the cutting performance of steel, heat treatment can be carried out, cold processing can increase the intensity. Often used in the manufacture of stamping parts and carburizing parts, such as stamping products, sockets, enamel products, automobile shell, etc..

- Q: How are steel coils used in the manufacturing of pressure vessels?

- Steel coils are used in the manufacturing of pressure vessels as they provide a strong and durable material for constructing the vessel's shell. The coils are typically rolled and welded to form the cylindrical shape of the pressure vessel, ensuring high structural integrity and the ability to withstand high pressure.

Send your message to us

Wood Pattern Prim Galvanized PPGI Steel Sheet

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 99 m.t.

- Supply Capability:

- 1200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords