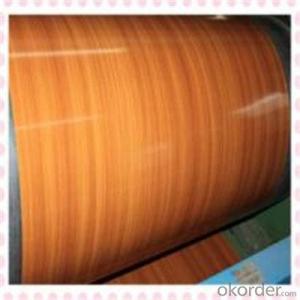

Wood Pattern Printing Galvanized PPGI Steel Sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of PPGI:

1. Zinc coating :40-180g( as required)

2. thickness:0.2-1.2mm

3. width:914-1250mm(914mm, 1215mm,1250mm,1000mm the most common)

4. coil id:508mm/610mm

5. coil weight: 4-10 MT(as required)

6. surface: regular/mini/zero spangle, chromated, skin pass, dry etc.

Festures of PPGI:

Building industry | Outdoor application | Roof, structural balcony, panels, window sills, window frames, gates, garage doors |

Indoor application | Room doors, dividing walls, door frames, light house steel structures, sliding doors |

Specifications of PPGI:

Specifications | |

Name | buy wood grain design ppgi!bs approved printed ppgi!prime quality cr steel coil |

Full name | Galvanized ,Galvalume,Pre-paited galvanizing,Pre-paited galvalume |

Basic material | Cold Roll |

Color of the PPGI and PPGL | Any color in RAL |

Standard | AISI, ASTM, BS, DIN, GB, JIS |

Spangle | Normal / Min / Zero |

Thickness | 0.14mm-2.0mm |

Width | 750mm to 1250mm |

Images of PPGI:

FAQ:

1.What about the delivery.

We can arrange the shipment about 15-25 days after the deposit.

2.What about payment term?

30% T/T deposit, balance against B/L copy.

Full T/T payment if quantity less than MOQ.

3.How much about MOQ?

Normally 100pcs,but small order is acceptable as well.

- Q: I'm writing a story, and trying to find out how hot it needs to be for steel to turn into a gas.

- Steel is to broad. There are many types of steel with different melting/boiling points. Iron* has a boiling point of 5182 °F and a Heat of vaporization of 340 kJ·mol?1. iron is the main ingredient of steel, along with carbon and other various elements.

- Q: Hi, I would like to know if steel is an important material in desalination plants. If it is, could you specify what type of steel is used (i.e. flat steel products, long steel products, etc). Thanks.

- If stainless steels were used they would have to be high grade, high Chromium-Nickel alloyed stainless steels. The best in the range would be the Stainless Steel 316 series with superior corrosion resistance and strength. The downside to this is the expense. Carbon steel may be used but only if reinforced with a more corrosive resistant element

- Q: where can i find information online about steel residential homes that use solar energy?

- Steel okorder

- Q: How are steel coils used in the production of agricultural implements?

- Steel coils are used in the production of agricultural implements as they are formed and shaped into various components such as blades, tines, or plowshares. These sturdy and durable steel components are then assembled into agricultural machinery like plows, cultivators, or harrows, which are essential for tasks like tilling soil, planting crops, and harvesting. The strength and resilience of steel make it an ideal material for agricultural implements, ensuring they can withstand the demanding conditions of farming and contribute to efficient and effective agricultural operations.

- Q: How are steel coils coated for corrosion resistance?

- Steel coils are typically coated for corrosion resistance using various methods such as hot-dip galvanizing, electroplating, or applying a protective layer of paint or powder coating.

- Q: How are steel coils used in the production of HVAC systems?

- Steel coils are used in the production of HVAC systems as they serve as the primary component for heat transfer. These coils are responsible for absorbing heat from the surrounding air and transferring it to cool the interior of a building. Additionally, steel coils are used for the condenser coils in HVAC systems, where they aid in the removal of heat from the refrigerant, allowing for efficient cooling and dehumidification.

- Q: I want to hear from those who own a scandium revolver. I know that scandium makes for a much lighter gun than steel, but how do they hold up durability-wise? Is their lifespan shorter than a comparable steel revolver?

- You know, I've kind of wondered about that too. Admittedly Scandium is a rather durable material, no contest there... but from the perspective of a machinist who has played with said Scandium in the past... it seems to *flake* on the blanchard grinders... hell, even fly cutting it acts kinda weird. I like steel because it's predictable, it has a fatigue point that is predictable... and when that fatigue point is met (limits of elastic modulus met by repetitive stress/strain exertions) it's fairly obvious. You get cracking, warping, and sometimes stretch marks... (yes, you can get *stretch marks* on steel). Scandium... I don't know. I don't know if it'll start cracking when it finally fatigues... or if it'll just let go all at once. Anyways, I don't think I'd worry too much about your revolver. It'll hold up I'm very sure (they've been around for years and people have put many, many rounds through them). Call me odd, but I'm a fan of steel. It's conventional, inexpensive (relatively speaking), and utterly durable.

- Q: So today I was bored and was reading a shotgun shell box,the box was slug 12ga.I noticed it said not to be used in Damascus steel or twist barrel.It was to my understanding that Damascus steel is very strong and many stories came from what it could cut when used in a blade or sword.The little bit of info that i could find was that Damascus used earlier in the turn of the century on shotguns should not be fired unless special maintenance has been given and check out by gunsmith.So is Damascus not strong like i thought and not be able to handle higher pressure or why the reason for the warning?*

- Damascus steel in gunmaking Prior to the early 20th century, all shotgun barrels were forged by heating narrow strips of iron and steel and shaping them around a mandrel.[22][23] This process was referred to as laminating or Damascus and these barrels were found on shotguns that sold for $12.[22][23] These types of barrels earned a reputation for weakness and were never meant to be used with modern smokeless powder, or any kind of moderately powerful explosive.[23] Because of the resemblance to Damascus steel, higher-end barrels were made by Belgian and British gun makers.[22][23] These barrels are proof marked and meant to be used with light pressure loads.[22] Current gun manufacturers such as Caspian Arms make slide assemblies and small parts such as triggers and safeties for Colt M1911 pistols from powdered Swedish steel resulting in a swirling two-toned effect; these parts are often referred to as Stainless Damascus.[24]

- Q: How are defects in steel coils detected and resolved?

- Defects in steel coils are typically detected through various non-destructive testing methods such as visual inspection, ultrasonic testing, magnetic particle testing, and eddy current testing. Once a defect is identified, it is resolved through processes like grinding, polishing, welding, or cutting out and replacing the affected area. The specific resolution method depends on the type and severity of the defect, ensuring that the steel coils meet the required quality standards before further processing or usage.

- Q: How do steel coils contribute to energy savings in buildings?

- Steel coils contribute to energy savings in buildings by being used in various applications that help improve insulation and reduce heat transfer. They are commonly used in HVAC systems, where they act as heat exchangers, transferring heat between air streams. Steel coils with high thermal conductivity ensure efficient heat transfer, allowing for effective cooling or heating of air without excessive energy consumption. Additionally, steel coils are utilized in the construction of insulated walls and roofs, forming an integral part of the building envelope. This helps minimize thermal bridging, preventing heat loss or gain through the building's structure. By improving insulation and reducing energy transfer, steel coils play a crucial role in enhancing the overall energy efficiency of buildings, leading to significant energy savings.

Send your message to us

Wood Pattern Printing Galvanized PPGI Steel Sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords