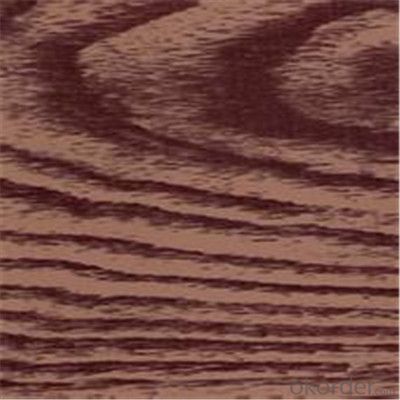

Wood Pattern Coated Galvanized PPGI Steel Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 45 m.t.

- Supply Capability:

- 1200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of Glove:

1. Zinc coating :40-180g( as required)

2. thickness:0.2-1.2mm

3. width:914-1250mm(914mm, 1215mm,1250mm,1000mm the most common)

4. coil id:508mm/610mm

5. coil weight: 4-10 MT(as required)

6. surface: regular/mini/zero spangle, chromated, skin pass, dry etc.

Festures of Glove:

1) Buildings and constructions: roofing, ceilings, gutters, venting lines, indoor decorations, window frames, etc.

2) Electrical appliances: computer shells, washing machines, refrigerators, dehumidifiers, video recorders, water heaters, etc.

3) Agricultural equipments: troughs, feeding tools, agricultural driers, irrigation channels, etc.

4) Vehicle parts: back-seat plates of buses and trucks, conveying systems, oil tanks, etc

Specifications of Glove:

Specifications | |

Name | buy wood grain design ppgi!bs approved printed ppgi!prime quality cr steel coil |

Full name | Galvanized ,Galvalume,Pre-paited galvanizing,Pre-paited galvalume |

Basic material | Cold Roll |

Color of the PPGI and PPGL | Any color in RAL |

Standard | AISI, ASTM, BS, DIN, GB, JIS |

Spangle | Normal / Min / Zero |

Thickness | 0.14mm-2.0mm |

Width | 750mm to 1250mm |

Images of Glove:

FAQ:

1.What about the delivery.

We can arrange the shipment about 15-25 days after the deposit.

2.What about payment term?

30% T/T deposit, balance against B/L copy.

Full T/T payment if quantity less than MOQ.

3.How much about MOQ?

Normally 100pcs,but small order is acceptable as well.

- Q: i'm looking into pedal steel guitars, and I would like some suggestions or links and info on what kind i should get.

- Try okorder -The Art of Steel Guitar/ Steel guitar players -Take it away Leon- McAuliffe and 'Speedy West' were a couple greats. In the late '50s, Speedy was playing a Fender 1000 Pedal steel. He often did duets with Jimmy Bryant The Fastest Guitar Player In The Country! / note also the 'Emmons Guitar Company':

- Q: I work the Copper plating line at a custom plating facility in MI.I like to use jumper cables with the jumper cable clamps to help confirm electric current is getting to my parts that I am plating. The acids in the Acid copper is constantly eating the steel and copper clamps. WIll I get a good enough current through stainless steel clamps? I use stainless steel hooks, but our maintenance man thinks that is one of the reasons why I have prblems with my parts turning out. I still think it has to do with the clamps getting eatin up. My question is Is stainless steel as good or reliable enough to run an electrical current to my parts if I am using stainless steel or is it best to use another method to try and get a better connection.Please state your sources or experience with working with electricity. I need to get honest answers and not this is my opinion. We are talking about my making a living so this is important to me so I can bring food home to my table. Thanks for all the help.

- Stainless steel is not such a good conductor as copper and the only metal with better conductivity is silver. Additionally, stainless steel will corrode in certain very corrosive environments without the presence of oxygen - i.e. when immersed in salt water. If you're getting problems caused by corrosion of the copper contacts you use there may well be a trade off so my advice is to do a trial and see what works best. You can check the conductivity of metals by simple online search for the period table:

- Q: What are the common methods of packaging steel coils for international shipping?

- There are several common methods of packaging steel coils for international shipping. These methods are designed to ensure the safety and security of the coils during transit. One method is the use of wooden crates. The steel coils are placed on wooden pallets and secured with steel bands or straps. The coils are then covered with wooden boards or plywood and nailed or screwed in place to create a sturdy crate. This method provides excellent protection against damage and ensures that the coils remain in place during transportation. Another method is the use of steel frames or skids. The steel coils are placed on steel skids or frames that are designed to support the weight and shape of the coils. The coils are then secured to the skids or frames with steel bands or straps. This method offers a high level of stability and protection, and is commonly used for larger or heavier coils. In addition to wooden crates and steel frames, steel coils can also be packaged using steel containers or shipping containers. These containers are specially designed to transport heavy or bulky items and provide a secure and protective environment for the coils. The coils are loaded into the container and secured with steel bands or straps to prevent movement during transit. Regardless of the packaging method used, it is important to ensure that the steel coils are properly protected from moisture, corrosion, and other potential hazards. This may involve the use of moisture-resistant materials such as plastic or wax paper, as well as the application of protective coatings or wraps. Overall, the common methods of packaging steel coils for international shipping include wooden crates, steel frames or skids, and steel containers. These methods are chosen based on the size, weight, and specific requirements of the coils, and aim to provide maximum protection and security during transit.

- Q: Can steel coils be coated with organic materials?

- Yes, steel coils can be coated with organic materials.

- Q: How long do steel coils last?

- The lifespan of steel coils can vary depending on several factors, including usage, maintenance, and environmental conditions. However, with proper care and regular maintenance, steel coils can typically last for several decades.

- Q: How are steel coils used in the production of heating systems?

- The production of heating systems relies on the utilization of steel coils in various ways. One primary application of steel coils in heating systems involves their incorporation in the construction of heat exchangers. Heat exchangers serve a vital purpose in the transfer of heat from one medium to another within the heating system. Typically, the steel coils are shaped into tubes or fins, which maximize the surface area for optimal heat transfer. In a typical heating system setup, the steel coils allow hot gases or liquids to pass through them, while another medium, such as air or water, flows over or through the coils. This arrangement facilitates the efficient transfer of heat energy from the hotter medium to the cooler one, effectively heating the air or water for distribution throughout the heating system. Steel coils are also employed in the production of radiant heating panels or floor heating systems in heating applications. In these instances, the steel coils are usually embedded within a panel or positioned beneath the flooring. When electricity or hot water passes through the coils, they heat up and emit heat to the surrounding environment. This particular heating system type boasts high efficiency and ensures a comfortable and evenly distributed heat output. Moreover, steel coils are integral components of heating systems such as boilers, furnaces, and heat pumps. These heating system units often require the use of steel coils due to their excellent heat transfer capabilities and durability. The integration of steel coils into the design of these units guarantees efficient and reliable heat generation and distribution. In summary, steel coils play a critical role in the production of heating systems as they enable efficient heat transfer, provide durability, and facilitate the generation and distribution of heat.

- Q: hello, just wondering if there is such a thing as a stainless steel coating for my aluminum muffler prior to installation. Yes, i suppose you can say that im cutting corners, but my current finances wont allow me to pay full price for a stainless steel one, thnx

- No, cheap parts or expensive parts are your choices. The cheap ones...you hope they last long enough for you to get a new car before they wear out.

- Q: How are steel coils stored and transported?

- Steel coils are typically stored in large warehouses or outdoor storage yards. They are stacked horizontally on top of each other, with wooden or steel supports placed between each coil to prevent damage. When it comes to transportation, steel coils are usually loaded onto flatbed trucks, railcars, or shipping containers. Specialized equipment such as coil racks or coil cradles may be used to secure and stabilize the coils during transport.

- Q: What is the purpose of coating steel coils?

- The purpose of coating steel coils is to provide protection against corrosion, enhance durability, and improve the aesthetic appearance of the steel. Coatings create a barrier between the steel surface and the environment, preventing moisture, chemicals, and other corrosive elements from reaching the metal. Additionally, coatings can offer additional benefits such as heat resistance, UV protection, and improved paint adhesion, making the steel coils suitable for a wide range of applications in various industries.

- Q: What are the common coil coating materials?

- The common coil coating materials include polyester, polyurethane, polyvinylidene fluoride (PVDF), and silicone-modified polyester (SMP).

Send your message to us

Wood Pattern Coated Galvanized PPGI Steel Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 45 m.t.

- Supply Capability:

- 1200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords