Wide Aluminum Roof Coil - Coated and Prepainted Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Coated Aluminum Coil /Prepainted Aluminum Coil

l Product Information

1 | Alloy: | A1100, A1050, A1060,A3003, A3004, A3005, A3105 , A5052, , A5754, A8011 etc. |

2 | Temper: | H14, H16, H18, H24 etc. |

3 | Thickness: | 0.2mm - 2.0mm |

4 | Width: | 15mm - 1600mm |

5 | Color: | chromic,white,metallic and so on(Customized, choose from RAL color chart or refer to customers' counter sample.) |

6 | Coating: | Polyester(mainly),Fluorocarbon(mainly),polyurethane and epoxy coating ect. |

7 | Coating thickness: | PVDF≥25 micron; PE≥18 micron. |

8 | Surface Quality: | be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use. |

9 | Mechanical Property: | Chemical Composite and Mechanical Property are meted with GB/T, ASTM, ENAW Standard. |

10 | Interior diameter: | 105mm or 405mm or 505mm |

11 | Coating hardness: | (pencil hardness) more than 2H |

12 | Impact resistance: | no cracking and peeling(≥50kg/cm) |

13 | Flexibility(T-bend) : | ≤ 2T |

14 | MEK resistance: | more than 100 |

15 | Application: | roofs, facade cladding, ceilings, aluminum curtains, composite panels, pipe wrap, advertisement plates, instrument panels, and other uses. |

l Product Information

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirements

Delivery detail: about 25 days from received original L/C or advance payment.

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

Aluminium coil is a popular product in the market of CNBM. With advanced technology and equipment, CNBM has sold its hight quality aluminium coil to the world.

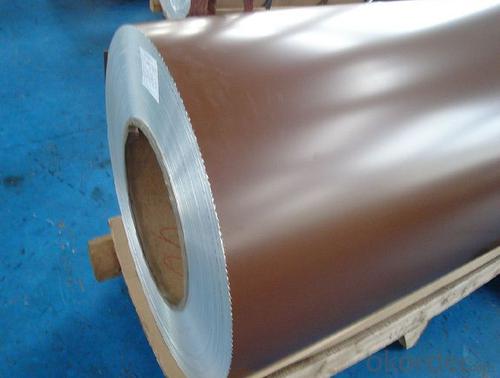

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q: What certifications might be necessary for the production, sale, or use of aluminum coils?

- <p>Aluminum coils may require various certifications depending on their intended use and the standards set by different countries or industries. Common certifications include ISO 9001 for quality management systems, ISO 14001 for environmental management, and specific industry standards such as ASTM or EN standards for material properties and safety. For construction or automotive applications, additional certifications like CE marking in Europe or DOT certification in the US may be necessary. It's crucial to consult with industry standards and regulatory bodies to determine the exact certifications required for a specific application.</p>

- Q: Are there any limitations or restrictions on the use of aluminum coils?

- Yes, there are limitations and restrictions on the use of aluminum coils. Some of the limitations include the maximum operating temperature, which is typically lower compared to other metals, such as copper. Aluminum coils may also have lower electrical conductivity, making them unsuitable for certain applications that require high conductivity. Additionally, the corrosion resistance of aluminum coils can be compromised in certain environments, necessitating protective coatings or alternative materials. Lastly, the strength and durability of aluminum coils may be lower compared to other materials, which may limit their use in certain high-stress applications.

- Q: What are the different tempers available for aluminum coils?

- There are several different tempers available for aluminum coils, each offering unique characteristics and properties. The most common tempers include: 1. O Temper: Also known as annealed or soft temper, this is the softest and most ductile temper available. It is characterized by low strength and high formability, making it suitable for applications that require extensive forming or bending. 2. H Temper: The H temper series includes various levels of work hardening, resulting in increased strength and reduced formability compared to the O temper. The H temper range includes H1X, H2X, H3X, H4X, H5X, and H6X, with each subsequent number indicating a higher level of work hardening. These tempers are commonly used in applications that require moderate to high strength. 3. T Temper: The T temper series, also known as heat-treated tempers, involves thermal treatments to achieve a specific combination of strength and formability. The most common T tempers include T3, T4, T6, and T7. T3 and T4 are solution heat-treated and naturally aged, providing a good balance of strength and formability. T6 and T7 are solution heat-treated and artificially aged, resulting in higher strength but reduced formability. 4. F Temper: The F temper, also known as as-fabricated temper, is obtained by hot working or cold working the material without subsequent thermal treatments. It offers improved strength and hardness compared to the O temper but lower than the H and T tempers. These different tempers allow aluminum coils to be used in a wide range of applications, from automotive parts and aerospace components to building materials and consumer goods. The choice of temper depends on the specific requirements of the application, including desired strength, formability, and corrosion resistance.

- Q: Explain the distinctions between cold rolled aluminum coils and hot rolled aluminum coils, focusing on the manufacturing process and resulting properties.

- <p>Cold rolled aluminum coils are produced by rolling aluminum at room temperature, resulting in a smoother surface and tighter dimensional tolerances. They have higher strength and hardness due to cold working. Hot rolled aluminum coils, on the other hand, are rolled at high temperatures, which allows for larger thickness reductions and creates a rougher surface. Hot rolled coils are generally softer and more ductile, with lower strength and hardness compared to cold rolled coils. The choice between the two depends on the specific application requirements for strength, surface finish, and formability.</p>

- Q: What are the strength properties of aluminum coils?

- High tensile strength, excellent formability, and good resistance to corrosion are among the strength properties exhibited by aluminum coils. These coils are favored in various industries like automotive, aerospace, and construction due to their high strength-to-weight ratio. They can endure heavy loads without deforming or breaking, as well as resist fatigue. Furthermore, aluminum coils offer easy shaping and bending without compromising their structural integrity, thanks to their excellent formability. Additionally, the natural oxide layer of aluminum acts as a protective barrier against corrosion, rendering aluminum coils highly resistant to rust and other forms of degradation. In conclusion, the versatility and reliability of aluminum coils make them an ideal material for a wide range of applications.

- Q: Can aluminum coils be used in automotive applications?

- Yes, aluminum coils can be used in automotive applications. Aluminum is a lightweight and corrosion-resistant material, making it a suitable choice for various automotive components, including coils. Its high thermal conductivity also allows for efficient heat transfer, making it beneficial for applications such as radiators and air conditioning systems.

- Q: This question asks for a comparison between single-coil and multi-coil aluminum tubes, highlighting their differences.

- <p>Single-coil aluminum tubes are made with a single layer of aluminum wound into a cylindrical shape, offering simplicity and ease of manufacturing. They are typically used in applications requiring basic heat exchange or formwork. In contrast, multi-coil aluminum tubes consist of multiple layers of aluminum wound together, which can provide greater strength and durability. They are often utilized in more demanding applications where higher pressure resistance and thermal efficiency are required, such as in high-performance heat exchangers or industrial processes. The multi-coil design also allows for better heat distribution and can handle more stress without deformation.</p>

- Q: Are aluminum coils recyclable?

- Indeed, recyclability applies to aluminum coils. As one of the most easily recyclable substances, aluminum can be recycled ceaselessly without compromising its integrity. The process of recycling aluminum coils entails melting them down to create fresh coils or alternative aluminum goods. This practice not only diminishes landfill waste but also conserves energy and resources necessary for manufacturing new aluminum from primary materials. Opting for the recycling of aluminum coils is an environmentally conscious decision that aids in the preservation of natural resources and the mitigation of greenhouse gas emissions.

- Q: Roll presented above 1 complete circles are brineling put on work roll after the new rolling, less than 12 volumes in the aluminum surface will be presented in the corresponding position of a straight roller, a roller indentation in the above, check the work roll above a pit. Replace the upper support roll for only a few days. Want to know what's going on?Should not be bearing problems, because the bearings have been used for almost 4 years, it should not be bearing problems, and now they are suspected of bending cylinder seal problems, oil seepage phenomenon.

- Substandard products how to leave the factory, if not for external reasons, that is, when the design and installation of bearings, specifically, you find manufacturers to come to repair

- Q: How do aluminum coils contribute to reduced carbon emissions?

- Aluminum coils contribute to reduced carbon emissions primarily due to their lightweight nature and recyclability. As aluminum is significantly lighter than other metals, such as steel, it reduces the overall weight of vehicles and machinery, subsequently improving fuel efficiency and reducing carbon emissions. Additionally, aluminum coils can be easily recycled, requiring much less energy compared to primary aluminum production, which results in lower greenhouse gas emissions.

Send your message to us

Wide Aluminum Roof Coil - Coated and Prepainted Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords