Aluminum Coils Inc Manta Aluminum Strip / Coil/ Sheet/ Plate 1070 0-h112

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Aluminum Strip / Coil/ Sheet/Plate 1070 0-H112 Description:

Aluminum Strip / Coil/ Sheet/Plate 1070 0-H112are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of theAluminum Strip / Coil/ Sheet/Plate 1070 0-H112:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

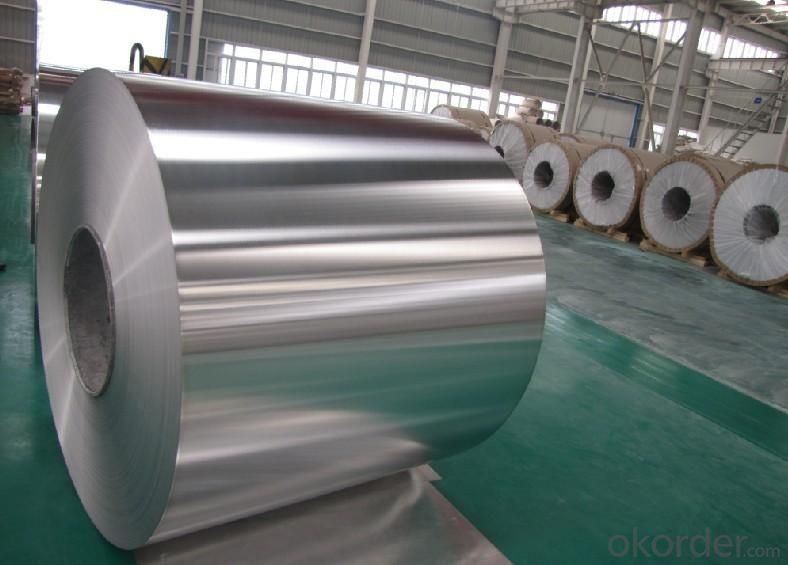

Images of the Aluminum Strip / Coil/ Sheet/Plate 1070 0-H112:

Aluminum Strip / Coil/ Sheet/Plate 1070 0-H112 Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: What are the potential applications of coil-anodized aluminum coils?

- Coil-anodized aluminum coils possess unique properties and advantages, allowing them to be employed in a wide range of potential applications. Here are some of the primary areas where they can be utilized: 1. Architectural: The distinct properties of coil-anodized aluminum make it well-suited for architectural purposes, including cladding, roofing, and facades. With its anodized coating, it offers increased durability, resistance to weather conditions, and color stability, making it suitable for outdoor use in various climates. Furthermore, the coils can be shaped and formed to create different architectural elements, providing design flexibility. 2. Transportation: Due to its lightweight nature, coil-anodized aluminum is ideal for transportation applications. It can be employed in the manufacturing of parts and components for the automotive, aerospace, and marine industries. The anodized coating enhances its corrosion resistance, making it suitable for exterior components and structures. 3. Electronics: Coil-anodized aluminum coils find utility in the field of electronics manufacturing. The anodized coating provides excellent electrical insulation, which is crucial in applications necessitating high conductivity and insulation. It can be utilized in the production of components such as heat sinks, casings, and connectors. 4. Signage and displays: The vibrant and long-lasting colors achieved through coil-anodizing make it a perfect material for signage and displays. The anodized coating ensures color stability against UV radiation and harsh weather conditions, rendering it suitable for both indoor and outdoor applications. It enables the creation of eye-catching and durable signage and displays. 5. Furniture and interior design: Coil-anodized aluminum coils can be employed in the manufacture of furniture and interior design elements. The anodized coating provides a smooth, durable, and scratch-resistant surface, making it suitable for applications like tables, chairs, wall panels, and decorative elements. The wide range of available colors and finishes allows for versatile design possibilities. 6. Industrial applications: Coil-anodized aluminum coils can be utilized in diverse industrial sectors. The anodized coating offers enhanced corrosion resistance, which is advantageous in industries such as chemical processing, food processing, and pharmaceuticals. It can be used in the production of tanks, containers, and equipment that require resistance against harsh chemicals and environments. 7. Energy and sustainable applications: The lightweight nature and durability of coil-anodized aluminum make it suitable for energy and sustainable applications. It can be employed in the manufacturing of solar panels, heat exchangers, and other energy-related components. The anodized coating provides protection against weathering and corrosion, ensuring long-term performance. In conclusion, coil-anodized aluminum coils have extensive and diverse potential applications, spanning across architectural, transportation, electronics, signage, furniture, industrial, and energy sectors. The combination of its lightweight nature, durability, color stability, and corrosion resistance makes it a versatile material for various industries and applications.

- Q: Tossing away an aluminum can wastes as much energy as pouring out half of that can’s volume of gasoline.what does that mean?

- Recycling aluminum saves the need from extracting new aluminum from ore, and saves the energy needed for that process.

- Q: at what state is aluminum at room temperature?what are aluminums physical properties?what is aluminum obtained from?

- Aluminum okorder /

- Q: What are the common surface finishes for aluminum coils in the automotive industry?

- Aluminum coils are extensively utilized in the automotive sector for various purposes due to their lightweight, high strength, and resistance to corrosion. To safeguard them from environmental elements and improve their appearance, aluminum coils in the automotive industry often undergo surface treatments. Anodizing is one of the most prevalent surface treatments for aluminum coils in the automotive industry. It is an electrochemical process that forms a thin protective layer on the surface of the aluminum coil. This treatment not only offers excellent corrosion resistance but also allows for customization of colors, making it a popular choice for automotive applications. Anodized aluminum coils can be found in a variety of colors and finishes, adding aesthetic appeal to vehicles. Another commonly employed surface treatment for aluminum coils in the automotive industry is powder coating. This technique involves applying dry powder paint onto the aluminum coil's surface and then curing it under heat to create a durable and long-lasting finish. Powder coating provides exceptional resistance to chipping, scratching, and fading, making it ideal for automotive components exposed to harsh conditions that require high durability. Moreover, powder coating offers a wide range of color options, enabling manufacturers to achieve the desired aesthetic appearance. Additionally, aluminum coils in the automotive industry may undergo other surface treatments like laminating, painting, or polishing, depending on specific application requirements. Laminating involves bonding a thin protective film onto the surface of the aluminum coil to provide additional protection against abrasion and chemical exposure. Painting entails the application of liquid paint onto the aluminum coil's surface, allowing for customization and protection against corrosion. Polishing, on the other hand, is a mechanical process that enhances the surface smoothness and appearance of the aluminum coil, resulting in a reflective and glossy finish. To summarize, the automotive industry commonly employs surface treatments such as anodizing, powder coating, laminating, painting, and polishing for aluminum coils. These treatments not only enhance the appearance of the aluminum coils but also provide protection against corrosion, abrasion, and other environmental factors, making them indispensable in the manufacturing of automotive components.

- Q: How do aluminum coils contribute to energy-efficient insulation?

- The role of aluminum coils in enhancing energy-efficient insulation cannot be overstated. To begin with, aluminum is an exceptional heat conductor, allowing it to effectively transfer heat away from its source and minimize heat penetration into insulated spaces. This quality ensures a stable and comfortable indoor environment, thereby reducing the need for excessive heating or cooling. Moreover, aluminum coils find extensive application in air conditioning and refrigeration systems, where they serve as the primary heat transfer medium. By efficiently absorbing and dissipating heat, these coils expedite the cooling process, resulting in reduced energy consumption and improved overall energy efficiency. Furthermore, the lightweight nature of aluminum makes it highly convenient for handling and installation in insulation systems. Its low weight provides flexibility and ease during manufacturing and transportation, leading to cost and energy savings. In addition, aluminum coils possess remarkable corrosion resistance, guaranteeing their durability and preventing the deterioration of insulation performance over time. This longevity ensures long-term energy efficiency as the insulation system remains effective without the need for frequent maintenance or replacement. In conclusion, aluminum coils significantly contribute to energy-efficient insulation through their effective heat conduction, facilitation of rapid cooling in air conditioning systems, reduced energy consumption, lightweight and easy handling, as well as long-lasting performance due to corrosion resistance. These qualities make aluminum coils the ideal choice for enhancing energy efficiency in insulation applications.

- Q: I wrap everything with aluminum foil and bake it in the oven -- fish, meat, vegetables. Is this really safe? Or safe when done occasionally? Or should I find a new way?

- I use aluminium foil often for baking however I use baking paper between the food and the foil. I am sure it is safe to use foil, however I find that on occasions the foil sticks to the food, so I use the non stick paper between. I hope this helps.

- Q: Never put oil in the water. Oil keeps the pasta from absorbing the sauce. Also add a little of the pasta water 3 Tbs. to the sauce. This helps sauce to adhere to pasta. The best remedy for pasta sticking. Use an aluminum stock pot. (tall pan). I don't know why but this works. I have using this stock pot for pasta for 40 years. I've tried stainless, non-stick, etc. they all stick. Except for the Aluminum.1 lb. of pasta, 4 qts. of water. 1Tbs. saltTurn burner to high,keep it therebring to boil then boil for 3 minutes, add 1 TBS salt, add pasta. Stir slowly 2 minutes, until the water boils. Cook tender enough for a fork to cut through but still a little firm

- cool tip. thanks.

- Q: How are aluminum coils different from other types of metal coils?

- Aluminum coils differ from other types of metal coils in several ways. Firstly, aluminum is a lightweight metal, making aluminum coils much lighter compared to coils made from other metals such as steel or copper. This lightweight property of aluminum makes it a popular choice for various industries where weight is a critical factor, such as aerospace and automotive industries. Secondly, aluminum coils have excellent corrosion resistance. Unlike other metals, aluminum forms a protective oxide layer on its surface when exposed to air, preventing further corrosion. This resistance to corrosion makes aluminum coils suitable for applications in humid and corrosive environments, such as marine or coastal areas. Additionally, aluminum coils possess high thermal conductivity. This means that aluminum can efficiently conduct heat, making it an ideal material for heat transfer applications like HVAC systems, refrigeration units, and radiators. The high thermal conductivity of aluminum coils allows for more efficient cooling or heating processes. Furthermore, aluminum is highly malleable and ductile, which means it can be easily shaped and formed without losing its structural integrity. This malleability makes aluminum coils flexible and versatile, allowing them to be manufactured into various shapes and sizes to meet specific industry requirements. Lastly, aluminum is a highly sustainable and recyclable material. It can be recycled repeatedly without losing its quality or performance, making aluminum coils an environmentally friendly choice. This recyclability factor contributes to reducing the environmental impact and promoting a circular economy. In summary, aluminum coils stand out from other metal coils due to their lightweight, corrosion resistance, high thermal conductivity, malleability, and recyclability. These unique properties make aluminum coils a preferred choice for a wide range of applications across different industries.

- Q: Can aluminum coils be embossed or textured?

- Yes, aluminum coils can be embossed or textured. Embossing or texturing involves the process of creating patterns or designs on the surface of the aluminum coil. This can be done through various methods such as mechanical or chemical processes. The embossed or textured surface adds aesthetic appeal and can also improve the functionality of the aluminum coil, such as enhancing its grip or reducing glare. These embossed or textured aluminum coils find applications in various industries such as construction, automotive, and packaging.

- Q: * How is hitting with a aluminum Wiffle Ball feel and work out?* Did you like the results you had hitting with a aluminum Wiffle Ball bat?

- I've used an aluminum Wiffle bat and it really feels a lot better to hit with than the yellow plastic number. The Aluminum bats are still super light, but there is a bit of weight to it, and that weight is kind of end-loaded, which you can really feel as you turn your wrists over. The net result is a swing that feels more like a real bat with the barrel whipping through the hitting zone instead of that flyswatter feel you get with the regular bats. Oh, and you definitely get more distance when you connect. Definitely. I actually played in a Wiffle Ball tournament a few years ago and used those bats. Someone said that they no longer make them or they've been outlawed or something along those lines.

Send your message to us

Aluminum Coils Inc Manta Aluminum Strip / Coil/ Sheet/ Plate 1070 0-h112

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords