Brazing Aluminum Coil - Roofing Ceiling Decorative Alloy Coated Color Prepainted Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Roofing Ceiling Decorative Alloy Coated Color Prepainted Aluminum Coil

Thickness | 0.1mm-10mm |

Popular Thickness | 0.1mm/0.2mm/0.25mm/0.3mm/0.6mm/0.8mm/1.0mm/1.2mm/1.5mm/2.0mm/3.0mm... |

Width | 20mm-2500mm |

inner diameter | 505mm 508mm 605mm |

Material | 1050,1060,1070,1100,1200,3003,3004,3005,5052,5005,5754,5083 |

Temper | O,H12,H14,H16,H18,H22,H24,H26,H32,H34,H36,H38,H111,H112 |

Surface | mill finish |

Packing | Export standard wooden pallets |

Payment Terms | 100% irrevocable L/C at sight or 30% T/T in advance as deposit,70% balance against the B/L copy |

Minimum Order Quantity | 5000kg |

Delivery time | 15-25 days after receiving L/C or deposit |

Remark | Specific requirement of alloy grade, temper or specification can be discussed at your request |

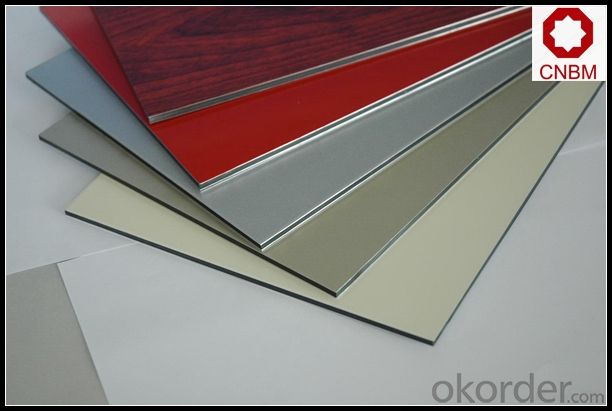

2. Application of Roofing Ceiling Decorative Alloy Coated Color Prepainted Aluminum Coil

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Roofing Ceiling Decorative Alloy Coated Color Prepainted Aluminum Coil

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

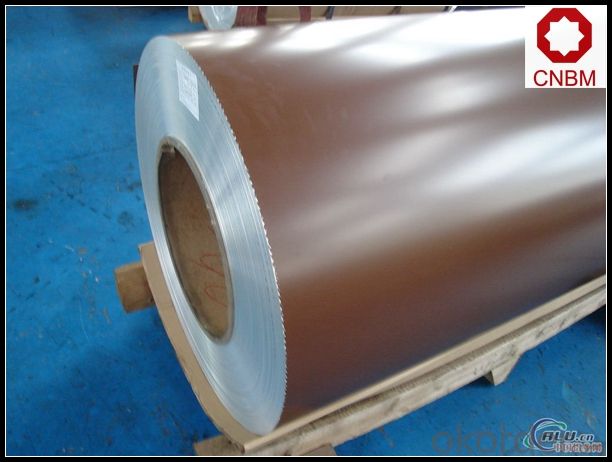

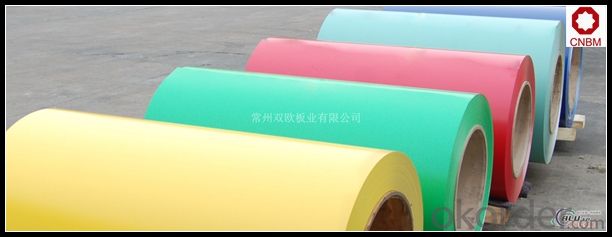

5. Image of Roofing Ceiling Decorative Alloy Coated Color Prepainted Aluminum Coil

6. Package and shipping of Roofing Ceiling Decorative Alloy Coated Color Prepainted Aluminum Coil

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can aluminum coils be used in the production of heat shields?

- Yes, aluminum coils can be used in the production of heat shields. Aluminum has excellent thermal conductivity, making it an effective material for transferring and dissipating heat. Additionally, it is lightweight and has good corrosion resistance, making it suitable for various applications where heat protection is required, such as in automotive or aerospace industries.

- Q: Which is better - a steel roof or an aluminum roof?

- Steel! SteelMaster steel roofs are Energy Star rated with Galvalume Plus coating and a 30 year warranty. Our steel roofs are custom designed and engineered to meet the loads and codes required for permitting.

- Q: What is the balanced equation for copper (I) oxide and Aluminum?

- Copper(I) oxide is a solid and so is aluminum. Any reaction that might occur would have to be at an elevated temperature. This is a thermite reaction in which copper(I) is reduced to copper metal (molten) and aluminum is oxidized to aluminum oxide. 3Cu2O(s) + 2Al(s) -- 6Cu(s) + Al2O3(s) ========= Follow up ========== Do you mean in aqueous solution? There won't be any copper(I) chloride in aqueous solution. CuCl is very insoluble in water, but will undergo disproportionation to form Cu2+ ions and copper metal. Therefore, you would actually have a solution of copper(II) chloride. Copper(II) chloride will react with aluminum to form copper metal and aluminum ions. Ordinarily aluminum won't react with copper(II) ions. The reaction does proceed in the presence of chloride ion. This is because the chloride ion will react with the Al2O3 layer on the surface of aluminum metal to make [AlCl4]^- which exposes the aluminum metal below, and thus a reaction can occur. 3Cu2+ + 2Al(s) -- 2Al3+ + 3Cu(s)

- Q: Can aluminum coils be used in the production of electronic components?

- Yes, aluminum coils can be used in the production of electronic components. Aluminum is a versatile and widely used metal in various industries, including electronics. It offers several advantages such as lightweight, high thermal conductivity, corrosion resistance, and excellent electrical conductivity. These properties make aluminum coils suitable for applications in electronic components like capacitors, transformers, inductors, and heat sinks. The use of aluminum coils in electronic components enables efficient heat dissipation, improved performance, and reduced overall weight of the electronic devices.

- Q: This question asks about the environmental impact of aluminum coils, including potential effects on the ecosystem and human health.

- <p>Aluminum coils, when produced and used responsibly, have minimal environmental impact. However, improper disposal or manufacturing can lead to pollution. Aluminum production requires significant energy, contributing to greenhouse gas emissions. During manufacturing, if not managed properly, can release harmful substances into the air and water. Yet, aluminum is highly recyclable, reducing its environmental footprint over time. When disposed of improperly, aluminum can contribute to litter and leach harmful substances into the soil and water, affecting wildlife and potentially human health. Responsible recycling and manufacturing practices are crucial to mitigate these effects.</p>

- Q: If this is true then how do I take my aluminums temperature without fear of breaking the themometer and get mercury all over it?

- Butting any metal against any other with an electrolyte can cause electron exchange and corrosion. (Liquid mercury is its own electrolyte.)There are alternatives such as thermocouples that only have a ceramic in contact with the aluminum.

- Q: Are aluminum pie pans and aluminum foil considered green products? They are most certainly recyclable. Thanks.?

- i would say no, because their only recycalable if they are clean. pluse the energy it takes to make them far outways the amount of times they could be re-used

- Q: This question asks for a comparison between single-coil and multi-coil aluminum tubes, highlighting their differences.

- <p>Single-coil aluminum tubes are made with a single layer of aluminum wound into a cylindrical shape, offering simplicity and ease of manufacturing. They are typically used in applications requiring basic heat exchange or formwork. In contrast, multi-coil aluminum tubes consist of multiple layers of aluminum wound together, which can provide greater strength and durability. They are often utilized in more demanding applications where higher pressure resistance and thermal efficiency are required, such as in high-performance heat exchangers or industrial processes. The multi-coil design also allows for better heat distribution and can handle more stress without deformation.</p>

- Q: and alsoHow many grams of the decay product will have formed after 8 days go by?The decay product is the new isotope created as a result of the positron decay of aluminum-24.In class my teacher didn't explain this completely but there's a question on the homework that me and even my mom (another teacher) can't find the answer to.

- so it 6000/ (2*8*24*60*60) 0.00434027778 grams have you heard of the internet an unless your mom is a chem teacher it doesnt mean much

- Q: What are the different types of surface treatments for aluminum coils?

- There are several different types of surface treatments available for aluminum coils. These treatments are designed to enhance the appearance, durability, and corrosion resistance of the aluminum. 1. Anodizing: This is a popular surface treatment method that involves creating a protective oxide layer on the surface of the aluminum. Anodizing can be done in various colors, which adds aesthetic value to the coils. It also improves resistance to corrosion and wear. 2. Painting: Aluminum coils can be coated with high-quality paints to provide a decorative and protective finish. The paint can be applied in a wide range of colors and finishes, such as matte, gloss, or metallic. Painting not only enhances the appearance but also provides additional protection against corrosion and UV rays. 3. Powder Coating: This is a process in which a dry powder is applied electrostatically to the aluminum coils and then cured under heat. Powder coating provides a durable and attractive finish that is resistant to chipping, scratching, and fading. It is available in a wide variety of colors and textures. 4. Chemical Conversion Coating: This treatment involves applying a chemical solution to the aluminum surface, which creates a thin layer of protective coating. The conversion coating improves the corrosion resistance of the aluminum and also provides a good base for subsequent paint or powder coating. 5. Brushing: Brushing is a mechanical surface treatment that involves using abrasive brushes to create a textured finish on the aluminum coils. This process can be used to achieve a brushed or satin-like appearance, which adds a unique aesthetic appeal to the coils. 6. Embossing: Embossing involves creating raised patterns or textures on the surface of the aluminum coils. This treatment not only enhances the visual appeal but also improves the strength and stiffness of the aluminum. Embossed coils are often used in architectural and decorative applications. Overall, the choice of surface treatment for aluminum coils depends on the specific requirements and desired appearance. Each treatment offers its own unique benefits in terms of durability, corrosion resistance, and aesthetic appeal.

Send your message to us

Brazing Aluminum Coil - Roofing Ceiling Decorative Alloy Coated Color Prepainted Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords