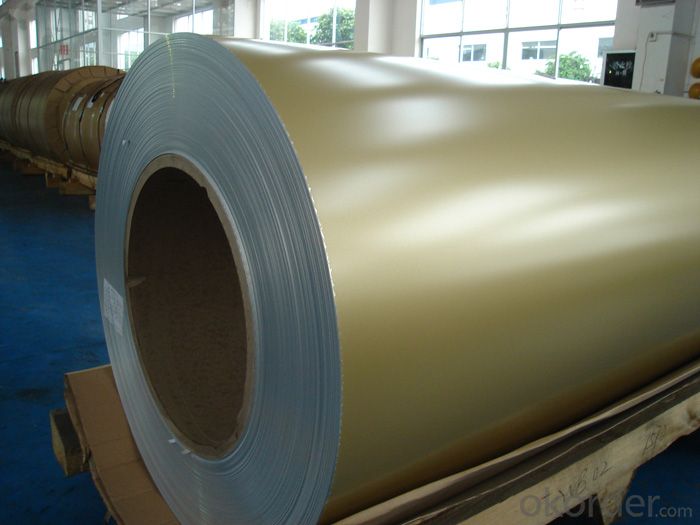

Aluminum Prepainted Aluminum Coil for Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Grade:

5000 Series

Surface Treatment:

Color Coated

Shape:

Rectangular

Temper:

T3-T8

Application:

Decorations

1. Grade

| Series: | 1100 etc. |

| Series: | 3003 3004 3005 etc. |

| Series: | 5006, 5052 |

| Series: | 8011 etc. |

2. Thickness

| Plate Thickness | 0.1mm, 0.12mm,0.15mm,0.20mm,0.25mm,0.28mm,0.3mm,0.35mm,0.38mm, 0.4mm,0.5mm, 0.53mm, 0.58mm,0.68mm,0.7omm,0.73mm,0.75mm, 0.90mm, 1mm, 1.2mm |

| Coil Thickness | 0.1mm, 0.12mm,0.15mm,0.20mm,0.25mm,0.28mm,0.3mm,0.35mm,0.38mm, 0.4mm,0.5mm, 0.53mm, 0.58mm,0.68mm,0.7omm,0.73mm,0.75mm, 0.90mm, 1mm, 1.2mm |

3. Colored aluminum foil Technical Data Of colorful coated aluminum coil :

| Item | Test Item | Standard | National Standard | Test Result |

| 1 | Color Difference | ECCA T3 | Delter E≤2.0 | Delter E≤1.0 |

| 2 | Gloss Difference | ECCA T2 | ≤10 | ≤5 |

| 3 | Coating Thickness | ECCA T1 | Two coating Min 23 mircron | ≥25 micron |

| Three coating Min 30 micron | ≥34 micron | |||

| 4 | Pencil Hardness | ASTM D3363 | ≥HB | HB |

| 5 | T-Bend | ASTM D4145 | ≤2T | ≤2T |

| 6 | Adhesion | ASTM D3359 | Grade 0 | Grade 0 |

| 7 | Impact | ASTM D2794 | ≤50kg.cm | ≤50kg.cm |

| 8 | Boiling Water Resistance | GB/T17748 | 2hr no change | 4hr no change |

| 9 | Slovent Resistance | ASTM D2248 | 200 times paint remaining | 500 times paint remaining |

| 10 | Acidity Resistance | ASTM D1308 | 5% HCL 24hrs no change | no change |

| 11 | Alkali Resistance | ASTM D1308 | 5% NAOH 24hrs Delter E≤2.0 | no change |

| 12 | Nitric Acid Resistance | AAMA620 | Delter E<5.0 | Delter E<5.0 |

| 13 | Oil Resistance | ASTM D1308 | 20# oil 24hrs no change | no change |

| 14 | Salt Spray Resistance | ASTM B117 | 4000hrs≤Grade 1 | no change |

| 15 | Abrasion Resistance | ASTM D968 | ≥5L/Micron | ≥5L/Micron |

| 16 | Contamination Resistance | GB/T9780 | ≤5% | <5% |

| 17 | Color Resistance | GB/T16259 | 4000hrs Delter E≤4.0 | 4000hrs Delter E≤3.0 |

| 18 | Gloss Losing Level | 4000hrs Delter E≤Grade 2 | 4000hrs Delter E≤Grade 2 | |

| 19 | Chalking | 4000hrs no change | 4000hrs no change |

- Q: This question asks whether it is safe to use aluminum cookware for pregnant women or individuals with health conditions.

- <p>While aluminum cookware is generally safe for most people, there are concerns about its potential health effects. Aluminum has been linked to cognitive issues and Alzheimer's disease, although the evidence is not conclusive. For pregnant women and those with health conditions, it is advisable to err on the side of caution. Opt for cookware made from stainless steel, cast iron, or non-stick materials without aluminum. If you must use aluminum cookware, avoid acidic or alkaline foods and ensure the cookware is not scratched, as this can increase aluminum leaching into food.</p>

- Q: Is it possible to utilize recycled aluminum in the manufacturing of automobiles and other types of vehicles?

- <p>Yes, recycled aluminum can be used to make automobiles and other vehicles. It is a common practice as aluminum is highly recyclable and retains its properties even after multiple recycling processes. Using recycled aluminum reduces the need for new aluminum production, which is energy-intensive, and contributes to sustainability efforts. Recycled aluminum is often used in vehicle components such as engine parts, body panels, and wheels, due to its lightweight, strength, and corrosion resistance.</p>

- Q: This question asks for the amount of energy needed to produce a single aluminum ingot.

- <p>The energy required to produce an aluminum ingot varies based on production methods and efficiency. On average, it takes about 14 to 25 kWh of electricity to produce one kilogram of aluminum. This high energy consumption is due to the electrolytic process used to extract aluminum from its ore, bauxite. The Hall-H茅roult process is the dominant method, which involves passing an electric current through a bath of molten cryolite to reduce aluminum oxide to aluminum metal. Energy efficiency in aluminum production has been improving, but it remains a significant factor in the overall carbon footprint of aluminum products.</p>

- Q: This question asks for examples of industrial processes that incorporate the use of aluminum.

- <p>Aluminum is widely used in various industrial processes due to its lightweight, corrosion resistance, and high strength-to-weight ratio. Some key industrial processes that utilize aluminum include the automotive industry for manufacturing car parts, the aerospace industry for aircraft construction, the construction industry for building materials, the packaging industry for food and beverage cans, and the electronics industry for components in devices. Aluminum is also used in the manufacturing of machinery, electrical equipment, and transportation equipment. Its versatility makes it a crucial material in many industrial applications.</p>

- Q: Explain how the inclusion of copper impacts the characteristics of aluminum alloys.

- <p>The addition of copper to aluminum alloys significantly enhances their strength and hardness. Copper is one of the most effective alloying elements for aluminum, leading to the formation of a series of age-hardenable alloys known as the 2xxx series. These alloys, such as 2024, are characterized by their high strength-to-weight ratio and are often used in aerospace applications, structural components, and transportation equipment. The copper atoms in the aluminum matrix form precipitates that strengthen the alloy through a process called precipitation hardening. However, the addition of copper also reduces the alloy's ductility and corrosion resistance, necessitating careful control of the copper content and heat treatment processes to optimize the alloy's properties for specific applications.</p>

- Q: Is it safe to use aluminum for making containers for food and beverages?

- <p>Yes, aluminum can be used to make containers for food and drink. Aluminum is a common material for food packaging due to its lightweight, durability, and resistance to corrosion. It forms a protective oxide layer that prevents the metal from interacting with the food, ensuring safety. However, it's important to note that aluminum containers should not be used for storing acidic foods or beverages for extended periods, as this can lead to leaching of aluminum into the food. Additionally, some studies suggest a potential link between aluminum and neurological disorders, though this is still a subject of debate.</p>

- Q: This question asks for a brief overview of the characteristics or qualities of aluminum nitride, a chemical compound.

- <p>Aluminum nitride (AlN) is a covalent, ceramic material known for its exceptional properties. It has a high thermal conductivity, which is about two-thirds that of copper, making it useful in electronics for heat dissipation. It's also an electrical insulator, exhibiting high electrical resistivity. Aluminum nitride is characterized by its high thermal stability, resistance to thermal shock, and excellent mechanical strength. It's chemically inert, resistant to most acids and alkalis, and has a high melting point of approximately 2200掳C. These properties make it suitable for applications in high-temperature electronics, as a substrate for semiconductor devices, and in the automotive industry for heat sinks and other heat management components.</p>

- Q: This question asks about the impact of aluminum on the aging process in living organisms.

- <p>Aluminum's effect on the aging process is a subject of ongoing research and debate. Some studies suggest that aluminum can accumulate in the body over time, potentially contributing to age-related diseases such as Alzheimer's. It is hypothesized that aluminum may interfere with cellular function, disrupt enzyme activity, and cause oxidative stress, which are all factors associated with aging. However, the exact mechanisms and the extent of aluminum's role in aging are not fully understood. It's important to note that the human body naturally has mechanisms to excrete aluminum, and the contribution of aluminum to aging is not conclusively proven. More research is needed to establish a clear link between aluminum exposure and the aging process.</p>

- Q: Are aluminum alloys suitable for use in the aerospace industry?

- <p>Yes, aluminum alloys are extensively used in aerospace applications due to their high strength-to-weight ratio, corrosion resistance, and good fatigue characteristics. They are particularly favored for constructing airframes, wings, and other structural components where weight savings are critical. The alloys are also used in manufacturing engine parts and heat exchangers due to their thermal conductivity and ability to withstand high temperatures. However, the specific alloy selection depends on the particular requirements of the application, such as temperature resistance, strength, and environmental conditions.</p>

- Q: Is it safe and common to use aluminum in food packaging?

- <p>Yes, aluminum is commonly used in food packaging due to its lightweight, durability, and excellent barrier properties against light, oxygen, and moisture. It is often used in the form of aluminum foil and aluminum-coated films or laminates to protect food and extend its shelf life. However, there are concerns about the potential health risks of aluminum exposure, and it's important to note that regulations and guidelines exist to ensure that aluminum levels in food packaging are safe for consumers.</p>

Send your message to us

Aluminum Prepainted Aluminum Coil for Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords