JIS Standard SS400 H beams with High Quality 100mm-150mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 15000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of JIS Standard SS400 H beams with High Quality 100mm-150mm:

1. Standard: JIS 3192

2. Grade: SS400 or Equivalent

3. Length: 10m, 12m as following table

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

Size and Mass of JIS Standard SS400 H beams with High Quality 100mm-150mm:

| Size (mm) | Mass (Kg/m) | Size (mm) | Mass (Kg) |

| 100*100*6.0 | 16.9 | 148*100*6.0 | 20.7 |

| 125*125*6.5 | 23.6 | 150*150*7.0 | 31.1 |

| 150*75*5.0 | 14.0 |

Packaging & Delivery of JIS Standard SS400 H beams with High Quality 100mm-150mm for Building Structures:

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The shipping date is dependent upon the quatity, how many sizes you want and the plan of production, but is typically 1 month to 2 months days from the beginning of production.

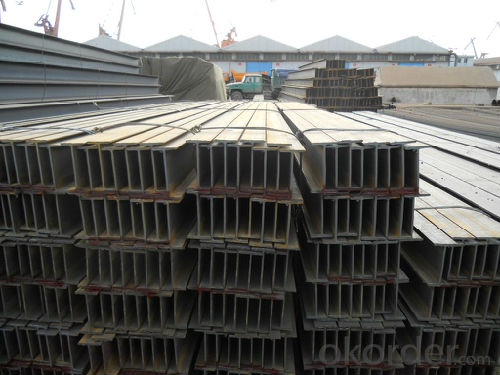

Images of JIS Standard SS400 H beams with High Quality 100mm-150mm:

* If you would like to get our price, please inform us the size, standard/material and quantity. Thank you very much for your attention.

- Q: Can steel H-beams be used for supporting elevated water tanks?

- Indeed, elevated water tanks can be supported by steel H-beams. Construction commonly utilizes steel H-beams due to their exceptional strength and capacity to bear heavy loads. These H-beams possess the ability to furnish the essential structural support necessary for elevated water tanks. By employing design and engineering techniques, the H-beams can be tailored to withstand the weight of the water tank, guaranteeing the stability and safety of the entire structure. Moreover, steel beams exhibit resistance to corrosion, rendering them appropriate for outdoor settings where water tanks are conventionally situated.

- Q: Are there any maintenance requirements for Steel H-Beams?

- Steel H-Beams require maintenance to ensure their structural integrity remains intact. Despite being a highly durable material, steel is still susceptible to various factors that can impact its stability over time. Here are some maintenance requirements to consider: 1. Conduct Regular Inspections: It is crucial to have qualified professionals regularly inspect the steel H-beams for any signs of damage, corrosion, or deformations. These inspections will help determine if any maintenance or repairs are needed. 2. Keep them Clean: Regular cleaning is necessary to remove dirt, dust, and debris that may accumulate on the surface of the steel beams. Use a mild detergent or specialized steel cleaner, followed by rinsing with water. Avoid abrasive materials or harsh chemicals that could damage the protective coating. 3. Prevent Corrosion: Steel H-beams are prone to corrosion, especially in humid or coastal environments. To prevent this, apply a protective coating or paint to act as a barrier against moisture and corrosive elements. Regularly inspect the coating for damage and touch up as needed. 4. Address Structural Issues: If any structural problems are identified during inspections, such as cracks, bends, or excessive deflection, immediate repairs should be carried out. Depending on the severity, repairs may involve reinforcing, welding, or replacing sections. It is essential to involve experienced engineers or contractors in steel structures for these repairs. 5. Monitor Load: Steel H-beams have specific load capacities. It is crucial to monitor and ensure that the applied loads do not exceed their design limits. Overloading can lead to structural failures or premature deterioration. Regularly assess the loads and consult professionals to ensure proper weight distribution and prevent potential issues. By adhering to these maintenance requirements, steel H-beams can maintain their structural integrity and longevity. Consult experts in steel structures or engineers for project-specific guidance.

- Q: How do steel H-beams perform in high-humidity environments?

- Steel H-beams generally perform well in high-humidity environments. The steel used in H-beams is typically coated or galvanized, which helps protect against corrosion caused by humidity. However, prolonged exposure to high humidity may still lead to some degree of corrosion over time. Regular maintenance and inspection are recommended to ensure the structural integrity of H-beams in such environments.

- Q: Can steel H-beams be used for long-span structures?

- Yes, steel H-beams can be used for long-span structures. Steel H-beams are commonly used in construction due to their high strength-to-weight ratio and versatility. They are capable of spanning long distances without the need for additional support columns or beams. The H-shape provides structural stability and distributes the load evenly, making it suitable for long-span structures such as bridges, high-rise buildings, and industrial facilities. Additionally, steel H-beams can be easily fabricated and connected, allowing for efficient construction and customization to meet specific design requirements. Overall, steel H-beams are a popular choice for long-span structures due to their strength, durability, and cost-effectiveness.

- Q: What are the different connection types for steel H-beams?

- There are several different connection types that can be used for steel H-beams, depending on the specific application and structural requirements. One common connection type is the welded connection. In this method, the H-beams are welded together using a combination of heat and pressure. This creates a strong and durable connection that is capable of withstanding significant loads. Welded connections are often used in heavy-duty applications where strength is a primary concern. Another connection type is the bolted connection. This involves using bolts or screws to connect the H-beams together. Bolted connections are advantageous because they can be easily disassembled and reassembled if needed. Additionally, they allow for a certain degree of flexibility and adjustment during installation. However, bolted connections may not be as strong as welded connections and may require periodic maintenance to ensure the integrity of the connection. Another option is the pinned connection. In this type of connection, the H-beams are connected using pins or dowels that allow for rotation at the joint. Pinned connections are often used in structures that require flexibility or where movement is expected, such as in bridges or seismic-resistant buildings. These connections allow for some degree of movement and rotation at the joint, which can help dissipate forces and reduce stress concentrations. In addition to these main connection types, there are also specialized connection methods such as moment connections and shear connections. Moment connections allow for the transfer of bending moments between the connected beams, while shear connections are designed to transfer shear forces. These specialized connections are often used in structural designs where specific loadings and requirements need to be considered. Overall, the choice of connection type for steel H-beams depends on factors such as the load requirements, structural design, expected movement, and ease of installation. It is important to consult with a structural engineer or professional to determine the most appropriate connection type for a specific application.

- Q: How do steel H-beams distribute load?

- Load distribution is achieved by steel H-beams through the utilization of their distinctive structural shape and material properties. H-beams are characterized by a horizontal top and bottom flange, connected by a vertical web in the center. This design enables the efficient distribution of loads by transferring them from the top flange to the web and then to the bottom flange, resulting in a balanced distribution of forces throughout the beam. The top and bottom flanges of H-beams are wider and thicker than the web, providing greater resistance to bending and torsional forces. When a load is applied to the beam, the top flange undergoes compression while the bottom flange undergoes tension. This distribution of forces helps the H-beam withstand bending and prevents it from collapsing under the weight of the load. Additionally, the vertical web in the center of the H-beam enhances stability and rigidity. It effectively resists shear forces that may act on the beam, preventing twisting or buckling. By connecting the flanges, the web ensures an even distribution of the load along the entire length of the beam, avoiding concentration in specific areas. The steel material used in H-beams is also pivotal in load distribution. Steel is renowned for its high tensile strength and durability, making it an ideal choice for structural applications. The strength of steel enables H-beams to bear heavy loads without deforming or failing. Moreover, steel possesses excellent stiffness and elasticity properties, guaranteeing that the H-beam maintains its shape and structural integrity under various loads. In conclusion, steel H-beams distribute load effectively through their unique shape and material properties. The horizontal flanges resist bending and tension forces, while the vertical web enhances stability and prevents twisting. The combination of these factors ensures efficient load distribution and the overall structural integrity of the system.

- Q: How do steel H-beams perform in mining and industrial facilities?

- Steel H-beams perform exceptionally well in mining and industrial facilities due to their high strength and durability. These beams provide robust structural support, enabling them to withstand heavy loads, vibrations, and harsh conditions commonly found in these environments. Additionally, their versatility allows for easy customization and installation, making them a preferred choice for various applications such as supporting heavy machinery, constructing conveyor systems, and creating overhead cranes. Overall, steel H-beams are reliable and efficient in enhancing the safety and operational efficiency of mining and industrial facilities.

- Q: Are Steel H-Beams resistant to pests or insects?

- Yes, steel H-beams are highly resistant to pests or insects. Unlike wooden beams, steel does not provide a food source or habitat for pests, making it an effective deterrent against any potential infestations.

- Q: What are the different types of connections used for steel H-beams to concrete?

- Steel H-beams can be connected to concrete using different methods. Some of the most commonly used methods are as follows: 1. Embedding steel plates or angles in the concrete and welding the steel H-beam to them. This creates a strong and rigid connection, but it requires skilled labor and may take more time. 2. Using bolts to connect the steel H-beam to the concrete. This method is versatile and relatively easy, allowing for adjustments and easy disassembly if necessary. 3. Employing shear connectors, such as headed studs or profiled steel plates, in composite construction. These connectors are welded to the steel H-beam and embedded in the concrete to transfer shear forces between the two materials. 4. Utilizing specialized mechanical devices, like steel connectors or clamps, to join the steel H-beam to the concrete. These connections are often employed for temporary or removable structures due to their quick installation and removal capabilities. The choice of connection type depends on various factors, including project requirements, load capacity, construction method, and budget. It is crucial to consult with a structural engineer to determine the most suitable connection type for steel H-beams to concrete in a specific application.

- Q: Can steel H-beams be used in the construction of industrial buildings?

- Yes, steel H-beams can be used in the construction of industrial buildings. H-beams, also known as I-beams, are commonly used in construction due to their strength, durability, and ability to support heavy loads. They are often used as structural support beams, providing stability and integrity to industrial buildings.

Send your message to us

JIS Standard SS400 H beams with High Quality 100mm-150mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 15000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords