Hot Rolled Structural Steel H-beam with all Size

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Structural Steel H-beam JIS Standard at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

Product Advantages:

OKorder's Structural Steel H-beam JIS Standard are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

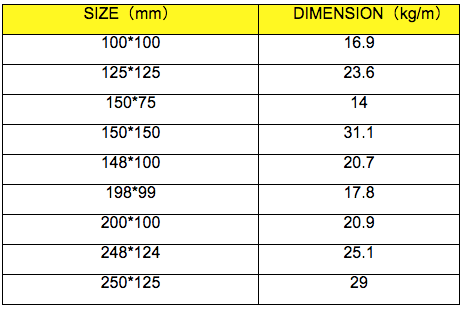

Specifications of Hot Rolled Structural Steel H-beam with all Size

1. Standard: GB700-88, Q235B2.

2. Grade: Q235, SS400 or Equivalent

3. Length: 6m,10m, 12m as following table

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

6. Sizes:

Usage & Applications of Hot Rolled Structural Steel H-beam with all Size

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

Packaging & Delivery of Hot Rolled Structural Steel H-beam with all Size

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

Production flow of Hot Rolled Structural Steel H-beam with all Size

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

FAQ

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

- Q: What are the different load types that steel H-beams can withstand?

- Steel H-beams possess excellent versatility and suitability for a wide array of applications due to their ability to withstand diverse load types. These load types that steel H-beams can endure include: 1. Uniformly Distributed Load (UDL): Steel H-beams effectively bear UDL, which is the evenly spread weight across the entire beam length. An example of UDL could be the weight of a floor or a roof. 2. Point Load: Steel H-beams are also capable of resisting point loads, which are concentrated forces applied at a specific point or area on the beam. Instances of point loads include the weight of heavy equipment or machinery placed directly on the beam. 3. Torsional Load: Steel H-beams possess the capacity to withstand torsional loads, which arise from a twisting force applied to the beam. This is crucial for structures experiencing rotational forces, such as bridges or towers subjected to wind or seismic activity. 4. Lateral Load: Steel H-beams can endure lateral loads, also known as horizontal loads that act perpendicular to the beam's axis. This is essential in countering lateral forces caused by wind or earthquakes. 5. Axial Load: Steel H-beams are specifically designed to resist axial loads, which are forces acting along the beam's axis. These loads can be compressive (pushing the beam together) or tensile (pulling the beam apart). Axial loads are commonly encountered in columns or vertical components of a structure. 6. Shear Load: Steel H-beams exhibit the capability to withstand shear loads, which transpire when two forces act in opposite directions parallel to the beam's cross-section. If not appropriately considered in the design, shear forces can cause beam deformation or failure. It is important to acknowledge that the load capacity of steel H-beams varies depending on factors such as beam size, shape, steel type, and specific design considerations of the structure. Thus, consulting engineering specifications and calculations is crucial to ensure the appropriate selection and application of H-beams based on the specific load requirements of a given project.

- Q: Can steel H-beams be used in the construction of sports arenas?

- Sports arenas can indeed utilize steel H-beams for construction purposes. These H-beams possess numerous benefits that render them suitable for this particular type of edifice. First and foremost, H-beams boast exceptional strength and durability, enabling them to bear the immense weight of expansive roof structures, seating areas, and other substantial loads commonly found in sports arenas. Moreover, steel H-beams exhibit a high resistance to corrosion, which proves essential in structures that are constantly exposed to diverse weather conditions. Furthermore, the versatility of steel permits the fabrication of H-beams in various sizes and shapes, guaranteeing that they can be customized to meet the precise design requirements of sports arenas. In conclusion, the utilization of steel H-beams in the construction of sports arenas ensures the creation of a secure and sturdy structure that can withstand the demands of accommodating large crowds and supporting intricate roof systems.

- Q: Are there any safety concerns related to steel H-beams?

- Yes, there are safety concerns related to steel H-beams. While steel H-beams are commonly used in construction and provide structural support, there are several factors that need to be considered to ensure safety. One of the primary concerns is the potential for structural failure. Steel H-beams can be subjected to various loads, including static, dynamic, and environmental forces. If the beams are not properly designed, fabricated, or maintained, they can experience structural weaknesses or defects that may lead to collapse or failure. Another safety concern is related to fire resistance. Steel H-beams, like other steel structures, can be vulnerable to fire. The high temperatures during a fire can weaken the steel, reducing its load-bearing capacity. Therefore, fire protection measures such as fire-resistant coatings or fireproofing materials should be implemented to enhance the safety of steel H-beams in fire-prone areas. Additionally, during construction or maintenance activities involving steel H-beams, there is a risk of accidents and injuries. Workers must follow proper safety protocols, including wearing personal protective equipment, using appropriate lifting and rigging techniques, and ensuring that the beams are securely fastened to prevent accidents such as falling or structural collapse. Lastly, the weight and size of steel H-beams can pose challenges during transportation, handling, and installation. Specialized equipment and trained personnel are required to safely lift, move, and position these heavy beams. Failure to adhere to safety procedures can result in accidents, injuries, or damage to property. In conclusion, while steel H-beams are a common and reliable choice for structural support, safety concerns exist. Proper design, fabrication, maintenance, fire protection measures, and adherence to safety protocols are essential to ensure the safe use of steel H-beams in construction and related activities.

- Q: Can steel H-beams be used for pedestrian bridges over highways?

- Yes, steel H-beams can be used for pedestrian bridges over highways. Steel H-beams are commonly used in bridge construction due to their high strength-to-weight ratio and structural stability. They can withstand heavy loads, making them suitable for supporting pedestrian traffic over highways. Additionally, steel H-beams can be prefabricated and easily transported to the construction site, allowing for efficient and cost-effective bridge construction. Proper design and engineering considerations must be made to ensure the bridge meets all safety standards and requirements.

- Q: What are the factors that affect the cost of steel H-beams?

- There are several factors that affect the cost of steel H-beams. Firstly, the current demand and supply in the market play a significant role. If there is high demand and limited supply, the cost is likely to increase. Additionally, the cost of raw materials, such as iron ore and coal, which are used in the production of steel, can impact the price of H-beams. Other factors include manufacturing and transportation costs, tariffs and taxes, currency exchange rates, and any additional specifications or customization required by the customer.

- Q: How do steel H-beams perform in high-temperature environments such as industrial furnaces?

- High-temperature environments, such as industrial furnaces, are well-suited for the performance of steel H-beams. Their exceptional thermal conductivity and high melting point are the primary factors contributing to this. These H-beams are typically constructed using structural steel, which is specifically designed to endure elevated temperatures without experiencing notable strength loss or compromised structural integrity. In such high-temperature conditions, steel H-beams effectively and rapidly distribute heat uniformly, thereby minimizing the chances of localized overheating. This plays a crucial role in averting any deformation or failure of the beams, ensuring the overall stability and safety of the structure. Moreover, steel H-beams possess a remarkable melting point, typically around 1370°C (2500°F) for carbon steel. This characteristic allows them to endure extreme heat without incurring significant damage. Even in the most intensely heated regions of an industrial furnace, where temperatures can surpass 1000°C (1832°F), steel H-beams remain structurally sound. Additionally, steel H-beams exhibit outstanding fire resistance properties. They do not combust or contribute to the propagation of fire, making them a reliable choice for high-temperature environments. This attribute is of particular significance in industrial furnaces, where the risk of fire is a considerable concern. All in all, steel H-beams are a suitable option for high-temperature environments like industrial furnaces. Their thermal conductivity, high melting point, and fire resistance properties enable them to withstand extreme heat while maintaining their structural integrity and ensuring safety.

- Q: Can Steel H-Beams be used in convention center or exhibition hall construction?

- Yes, Steel H-Beams can be used in convention center or exhibition hall construction. They are commonly used in such projects due to their high strength, durability, and ability to support heavy loads. Steel H-Beams provide structural integrity and can be easily fabricated and installed, making them a reliable choice for large-scale construction projects like convention centers and exhibition halls.

- Q: Can steel H-beams be used in the construction of telecommunications infrastructure?

- Yes, steel H-beams can be used in the construction of telecommunications infrastructure. H-beams are commonly used in construction due to their high strength-to-weight ratio, which makes them an ideal choice for supporting heavy loads. They provide excellent structural integrity and stability, making them suitable for various applications, including telecommunications towers, antennas, and equipment shelters. Steel H-beams can withstand extreme weather conditions and provide the necessary support for the installation and maintenance of telecommunications equipment. Additionally, they can be easily fabricated and assembled, allowing for efficient construction and flexibility in design. Overall, steel H-beams are a reliable and durable option for constructing telecommunications infrastructure.

- Q: What are the aesthetic options for steel H-beams?

- Steel H-beams, also known as I-beams, have a variety of aesthetic options that can enhance the appearance of different structures. Here are some of the available aesthetic options for steel H-beams: 1. Finishing: Steel H-beams can be finished in various ways to achieve different aesthetic effects. One popular choice is to leave the beams with a natural, raw steel finish, showcasing the industrial and rugged appeal of the material. Alternatively, the beams can be painted or powder-coated in different colors to match the overall design scheme of the structure or to create a contrasting visual effect. 2. Surface texture: Steel H-beams can also be treated to create different surface textures. For example, they can be sandblasted to achieve a rough, textured appearance that adds visual interest. Additionally, they can be polished or brushed to create a smoother and more refined look, which works well in contemporary or modern architectural designs. 3. Coating: To enhance both aesthetics and durability, steel H-beams can be coated with various materials. Galvanization is a common option, where a layer of zinc is applied to protect the steel from corrosion. The galvanized coating can have a shiny or matte finish, depending on the desired aesthetic outcome. Other coating options include epoxy, which can be applied in different colors, or even a clear protective coating to preserve the natural appearance of the steel. 4. Customized shapes: Steel H-beams can be customized into different shapes to suit specific aesthetic requirements. This involves altering the width, height, and thickness of the beams to create unique designs. Customized shapes can add visual interest and architectural appeal to structures, making them stand out in a visually striking manner. 5. Integration with other materials: Steel H-beams can be combined with other materials to create a visually appealing contrast. For example, incorporating wood or glass elements alongside the steel beams can create an interesting mix of textures and materials, making the structure more visually dynamic. In conclusion, the aesthetic options for steel H-beams are extensive. From various finishes and coatings to surface textures and shape customization, these options allow designers and architects to create visually appealing structures that cater to a range of architectural styles and preferences.

- Q: What are the mechanical properties of steel H-beams?

- Steel H-beams have several key mechanical properties that make them suitable for a wide range of applications. Firstly, H-beams have a high tensile strength, which means they can withstand significant amounts of tension or pulling forces without breaking or deforming. This property makes them ideal for use in structures that need to support heavy loads, such as bridges or high-rise buildings. H-beams also have excellent yield strength, which is the amount of stress a material can withstand before it starts to deform permanently. This property ensures that H-beams can resist bending or buckling under heavy loads, providing structural stability and preventing collapse. Another important mechanical property of steel H-beams is their stiffness or modulus of elasticity. This property determines how much a material will deform under a given amount of stress. H-beams have a high modulus of elasticity, which means they are relatively rigid and can maintain their shape and structural integrity even when subjected to significant loads. Additionally, steel H-beams have good fatigue resistance, allowing them to withstand repeated cycles of loading and unloading without failure. This property is crucial in structures subject to dynamic loads, such as bridges or cranes, where the material is constantly exposed to varying forces. Finally, H-beams have excellent weldability, enabling them to be easily joined together to create larger structures or to modify existing ones. This property is essential for construction projects that require flexibility and adaptability in design. Overall, the mechanical properties of steel H-beams, including high tensile strength, yield strength, stiffness, fatigue resistance, and weldability, make them a popular choice in structural engineering and construction applications.

Send your message to us

Hot Rolled Structural Steel H-beam with all Size

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords