Wholesale 201 Stainless Steel Sheet Embossed Sheets Plates

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Stainless steel which can be produced in different chemical, physical and mechanical properties, have high corrosion and heat resistance, mechanical strength, manufacturing ease, aesthetic appearance hygienic and long lasting properties.

STANDARDS

ASTM A240/A240M,ASME A240/A240,EN 10088-2, EN10028-7,JIS G 4305

| Decoration Stainless Steel Sheet / Plate | |

| Size | Thickness 0.02mm-3mm, Width and Length can be customized |

| Grade | SUS 201, 202, 304L/H, 316L/H, 321/H, 317/H, 347/H, 310S, 430, 409/L, 31803, 32750, 32760, etc |

| Standard | JIS,EN,ASTM,AISI |

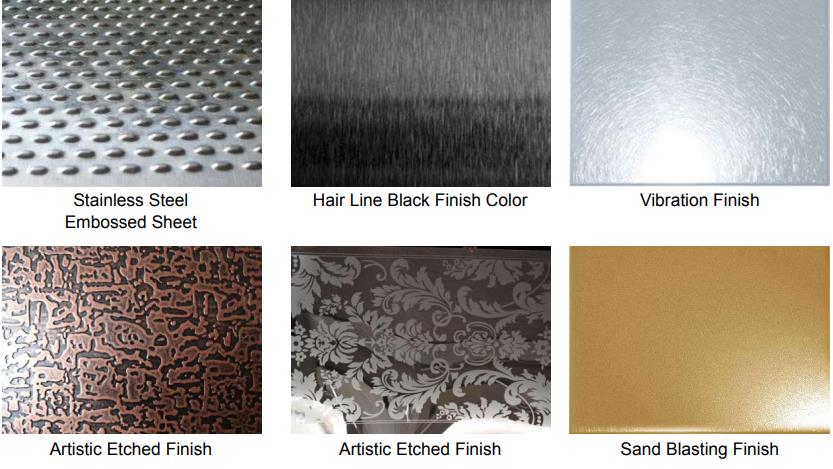

| Finish | 2B, HL, NO.4, BA, Mirror, Embossed, Colored, Vibration, Sand blasting, Artistic etched etc. |

| Application | Elevator, Carbin Decoration, Building Decoration, Architectural Decoration, Kitchen Decoration |

Stainless Steel Sheet Series

Stainless Steel Polished Sheet (8K Mirror, Hairline, Grit 240,320)

Embossed Stainless Steel Sheet

Etched Stainless Steel Sheet,

PVD Colored Stainless Steel Sheet,

Perforated Stainless Steel Plate

Chequered Stainless Steel Sheet

Packaging & Shipping

Application

Kitchen, Subway, Hospital, Door, Frame of Door, Structure, Machine, Pipe, Utensil, Internal Decoration of Elevator.

- Q: Can stainless steel sheets be used for decorative wall panels?

- Yes, stainless steel sheets can be used for decorative wall panels. Stainless steel is a versatile material that can be easily shaped and manipulated to create various designs and patterns. It is known for its sleek and modern appearance, making it a popular choice for contemporary and industrial-style interiors. Stainless steel sheets are available in different finishes, such as brushed, mirrored, or textured, allowing for further customization and adding visual interest to the wall panels. Additionally, stainless steel is resistant to corrosion, durable, and easy to clean, making it suitable for high-traffic areas or environments prone to moisture or humidity. Overall, stainless steel sheets can provide a stylish and functional solution for decorative wall panels.

- Q: How do you bend stainless steel sheets?

- To effectively bend stainless steel sheets, a combination of skill, knowledge, and the right tools is necessary. Follow these steps for successful bending: 1. Identify the specific grade of stainless steel you are working with as each grade possesses unique characteristics affecting malleability and bending response. 2. Prior to bending, ensure the stainless steel sheet is clean and devoid of any dirt or debris. Use a mild detergent and a soft cloth for surface cleaning. 3. Mark the precise bending line by measuring and indicating the desired spot. Utilize a ruler or straight edge for accuracy. 4. Select an appropriate bending tool based on the size and thickness of the stainless steel sheet. Options include a press brake, rolling machine, or bending machine. 5. Gradually apply pressure by placing the stainless steel sheet in the bending tool, aligning it with the marked bending line. Avoid excessive force to prevent cracking or deformation. 6. Adjust the bending angle as needed by repositioning the stainless steel sheet within the bending tool. Utilize the tool's adjustments or supplementary tools like clamps for precise angles. 7. Inspect the result by carefully removing the stainless steel sheet from the bending tool. Check for defects, cracks, or unevenness. Minor adjustments can be made using a rubber mallet or a hammer with a soft face. Keep in mind that bending stainless steel sheets requires practice and precision. Begin with smaller projects and gradually advance to more complex bends. If uncertain or lacking experience, consult a professional in metal fabrication for the best outcomes.

- Q: Can stainless steel sheets be used for furniture or fixtures?

- Yes, stainless steel sheets can be used for furniture or fixtures. Stainless steel is a durable and versatile material that is resistant to corrosion, making it an excellent choice for furniture and fixtures that are exposed to moisture or high humidity. It can be used for a variety of applications such as tabletops, countertops, shelves, cabinets, and even decorative accents. Stainless steel sheets can be easily fabricated into different shapes and sizes, allowing for customization to suit specific design requirements. Additionally, stainless steel has a modern and sleek appearance, making it a popular choice for contemporary and industrial-style furniture and fixtures.

- Q: Can stainless steel sheets be used for food preparation surfaces?

- Yes, stainless steel sheets can be used for food preparation surfaces. Stainless steel is a popular choice for food preparation surfaces due to its excellent properties. It is non-porous, which means it does not absorb any liquids or bacteria that can contaminate the food. Stainless steel is also resistant to corrosion, staining, and rusting, making it a durable and long-lasting option for food preparation surfaces. Additionally, stainless steel is easy to clean, as it can withstand high temperatures and is not affected by most cleaning agents. This makes it a hygienic choice for food preparation surfaces, as it can be thoroughly sanitized to prevent the growth of bacteria. Overall, stainless steel sheets are a safe and practical choice for food preparation surfaces.

- Q: How do I install stainless steel sheets?

- To install stainless steel sheets, you will need to follow a few steps: 1. Measure and prepare the area: Start by accurately measuring the area where you want to install the stainless steel sheets. Use a tape measure to determine the length and width of the space. Additionally, make sure the surface is clean, dry, and free from any debris or contaminants. 2. Cut the sheets: If the stainless steel sheets you have purchased are not already pre-cut to the desired size, you will need to cut them to fit the area. Use a metal cutting saw, such as a circular saw or an angle grinder with a metal-cutting blade, to make precise cuts. Make sure to wear safety goggles and work gloves while cutting to protect yourself from any flying debris. 3. Apply adhesive or screws: Depending on the method you prefer, you can either use an adhesive or screws to secure the stainless steel sheets to the surface. If you choose to use an adhesive, apply a thin layer of construction adhesive to the back of the sheet and press it firmly onto the surface. For added security, you can also use screws to fasten the sheets. Pre-drill holes into the stainless steel sheets and then screw them into place using stainless steel screws. 4. Secure the edges: Once the sheets are in place, secure the edges by using trim pieces or stainless steel molding. This will give your installation a clean and finished look while also providing additional protection to the edges of the sheets. 5. Clean and maintain: After the installation is complete, clean the stainless steel sheets using a mild detergent and a soft cloth. Avoid using abrasive cleaners or scrub brushes as they can scratch the surface. Regular cleaning and maintenance will help preserve the appearance and longevity of the stainless steel sheets. Remember, if you are unsure about any step of the installation process, it is always recommended to consult a professional or seek guidance from the manufacturer of the stainless steel sheets you have purchased.

- Q: What are the standard sizes and thicknesses of stainless steel sheets?

- Stainless steel sheets come in various standard sizes and thicknesses that are widely used in different industries and applications. The standard sizes typically range from 4 feet by 8 feet to 5 feet by 10 feet, although custom sizes can also be obtained based on specific requirements. Regarding thicknesses, stainless steel sheets are available in several standard options, including 20 gauge (0.036 inches), 18 gauge (0.048 inches), 16 gauge (0.060 inches), 14 gauge (0.075 inches), 12 gauge (0.105 inches), and 10 gauge (0.135 inches). These thicknesses refer to the nominal thickness, and actual thickness may vary slightly. It is important to note that stainless steel sheets can also be obtained in metric sizes, with common thicknesses ranging from 0.5 mm to 3 mm. This allows for flexibility and compatibility with international standards and specifications. Overall, the standard sizes and thicknesses of stainless steel sheets are determined by industry standards and customer requirements, ensuring wide availability and versatility for various applications such as construction, automotive, aerospace, and kitchen equipment manufacturing, among others.

- Q: How do I determine the hardness of stainless steel sheets?

- There are various techniques available for determining the hardness of stainless steel sheets. One commonly used method is the Rockwell hardness test, which involves measuring the depth of penetration of an indenter into the material. The Rockwell scale offers different scales for different materials, so it is essential to select the appropriate scale for stainless steel. To conduct the Rockwell hardness test, you will require a Rockwell hardness tester and either a diamond or tungsten carbide indenter. Begin by placing the stainless steel sheet on a stable, flat surface. Next, position the indenter on the surface of the sheet and apply a minor load. Once the minor load is applied, proceed to apply the major load until it reaches its maximum value. After the load has been applied and released, the hardness value will be displayed on the dial or digital display of the Rockwell hardness tester. This value corresponds to a specific hardness scale, such as HRC for stainless steel. It is important to remember that the Rockwell hardness test provides a relative measurement of hardness and may not accurately reflect the physical properties of the material. Moreover, the hardness of stainless steel can vary depending on factors such as alloy composition, heat treatment, and manufacturing process. Therefore, it is advisable to consult the material's specifications or conduct additional tests to obtain a more accurate and comprehensive understanding of the stainless steel sheet's hardness.

- Q: What's the difference between cold rolling and hot rolling of stainless steel plate?

- Cold rolling and hot rolling are different processes, and cold rolling is usually made by longitudinal rolling. Cold rolling process usually includes preparation of raw materials, pickling, rolling, degreasing, annealing (heat treatment), finishing and so on. Cold rolling takes hot rolling product as raw material, and the raw material should be removed before cold rolling so as to ensure the surface cleanness of cold rolling products.

- Q: Are stainless steel sheets suitable for architectural mesh applications?

- Yes, stainless steel sheets are highly suitable for architectural mesh applications. Stainless steel is a versatile and durable material that offers numerous benefits for architectural applications. It is resistant to corrosion, which is crucial for long-term performance in outdoor and high-moisture environments. Additionally, stainless steel has excellent strength and can withstand heavy loads, making it ideal for structural applications. Architectural mesh made from stainless steel sheets offers a unique combination of functionality and aesthetics. It can be used for a wide range of applications, including facades, cladding, sunshades, balustrades, and partitions. The mesh can be woven or welded into various patterns and shapes, allowing for creative and visually appealing designs. Stainless steel architectural mesh also provides excellent transparency and airflow, making it suitable for applications that require ventilation or light transmission. It can enhance the aesthetics of a building by creating a sense of openness while providing privacy and security. Moreover, stainless steel offers a high degree of customization. It can be finished in different colors and surface textures, allowing architects and designers to achieve their desired look and feel. Additionally, stainless steel is a sustainable material as it is fully recyclable and has a long lifespan, reducing the environmental impact of architectural projects. In conclusion, stainless steel sheets are highly suitable for architectural mesh applications due to their corrosion resistance, strength, versatility, and aesthetic appeal. They provide architects and designers with a wide range of options to create visually striking and functional structures.

- Q: Can stainless steel sheets be used for medical implant devices?

- Yes, stainless steel sheets can be used for medical implant devices. Stainless steel is a commonly used material in medical implants due to its high strength, corrosion resistance, and biocompatibility. It can be shaped into sheets and fabricated into various implantable medical devices such as orthopedic implants, dental implants, and cardiovascular stents.

Send your message to us

Wholesale 201 Stainless Steel Sheet Embossed Sheets Plates

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords