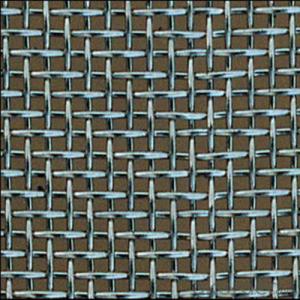

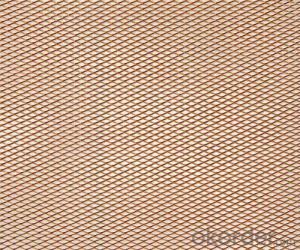

Mineral Screen Crimped Wire Mesh

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Mineral Crimped Wire Mesh

Material: stainless steel wire, high tensile steel, high carbon steel, low carbon steel,

Galvanized wire, clooured steel wire.

Crimp Methods: plain weaved, can be crimped(double crimp, intermediate crimp, lock crimp, flat top crimp, lock slot crimp,

Application: it is used extensively in the minerals extraction, food and chemical processing, water and waste treatment, and construction industries, coal industry, decorate area, etc.

Wire diameter: 0.025-16mm

Aperture: 0.025-100 mm

Width: 0.5-4 m

Length: 1-30m

- Q: Is steel wire mesh suitable for use in railway infrastructure?

- Yes, steel wire mesh is suitable for use in railway infrastructure. It is widely used for various applications such as fencing, reinforcement, and stabilization in railway tracks and structures. Steel wire mesh provides strength, durability, and resistance to harsh environmental conditions, making it an ideal choice for ensuring the stability and safety of railway infrastructure.

- Q: Can steel wire mesh be used for construction purposes?

- Yes, steel wire mesh can be used for construction purposes. It is commonly used in various construction applications such as reinforcing concrete structures, providing stability to walls and foundations, and for safety measures like fencing. The strength, durability, and versatility of steel wire mesh make it a reliable material for construction projects.

- Q: How does steel wire mesh resist rust and corrosion?

- Steel wire mesh resists rust and corrosion due to its composition and protective coating. Steel wire mesh is typically made from stainless steel, which is an alloy that contains chromium. Chromium is known to have excellent corrosion resistance properties. It forms a passive oxide layer on the surface of the steel, which acts as a protective barrier against rust and corrosion. Additionally, steel wire mesh is often coated with a layer of zinc through a process called galvanization. Galvanization involves immersing the steel mesh in a bath of molten zinc. This creates a zinc-iron alloy on the surface, providing an extra layer of protection against rust and corrosion. The combination of stainless steel and galvanization makes steel wire mesh highly resistant to rust and corrosion. This makes it suitable for various applications, both indoors and outdoors, where exposure to moisture, humidity, and other corrosive elements is likely. Whether used in construction, fencing, or industrial applications, steel wire mesh offers durability and long-lasting performance in challenging environments.

- Q: How is steel wire mesh used in geotechnical engineering?

- Steel wire mesh is commonly used in geotechnical engineering for various applications. One of the primary uses of steel wire mesh is in soil stabilization. When soil is weak or loose, it can lead to slope instability or erosion. Steel wire mesh is used to reinforce the soil and increase its strength and stability. It is typically installed horizontally or vertically in the ground to create a strong barrier that prevents soil movement and retains its shape. Steel wire mesh is also utilized in retaining walls and embankments. These structures are built to hold back soil or rock masses and prevent landslides or collapses. The mesh is installed within the soil or behind the retaining wall to reinforce it and provide additional strength. This helps to distribute the forces exerted by the soil or rock mass evenly, reducing the risk of failure. In addition, steel wire mesh is employed in erosion control systems. It is installed on slopes or riverbanks to protect the soil from erosion caused by water or wind. The mesh acts as a barrier, preventing the soil particles from being washed away or blown off. By stabilizing the soil and reducing erosion, steel wire mesh helps to maintain the integrity of the landscape and prevent environmental damage. Furthermore, steel wire mesh is used in geotechnical engineering for rockfall protection. In areas where there is a risk of rockfall, such as mountainous regions or along highways, steel wire mesh is installed to catch and contain falling rocks. The mesh is anchored to the slope or cliff face, creating a protective barrier that prevents rocks from reaching the ground and posing a hazard to people or structures below. Overall, steel wire mesh plays a crucial role in geotechnical engineering by providing reinforcement, stability, and protection to various structures and landscapes. Its versatility and durability make it a preferred choice for applications that require strength and resistance to environmental factors.

- Q: Can steel wire mesh be used for creating animal traps or snares?

- Yes, steel wire mesh can be used for creating animal traps or snares. The durability and strength of steel wire mesh make it a suitable material for constructing traps and snares to capture animals. Steel wire mesh can be shaped and formed into various designs to effectively capture and hold the targeted animal. Additionally, the small gaps between the wires in the mesh prevent animals from escaping once they are caught. However, it is important to note that the use of traps and snares for capturing animals may be subject to legal regulations and ethical considerations, so it is essential to ensure compliance with local laws and use these tools responsibly and humanely.

- Q: Can steel wire mesh be used for stage backdrops?

- Certainly! Stage backdrops can indeed utilize steel wire mesh. This material, known for its versatility, offers a myriad of advantages for stage design. Notably, it boasts durability and strength, providing a reliable surface for suspending props, lights, and other stage embellishments. The mesh's open structure allows for visibility and airflow, creating visually appealing backdrops that do not impede the audience's view of the performers. Moreover, steel wire mesh can be effortlessly manipulated and molded to produce a wide range of artistic effects. These effects may include adding texture, depth, or even crafting three-dimensional shapes. Furthermore, projecting lights and images onto the mesh can introduce an additional dimension to the stage design. Unquestionably, due to its adaptability, resilience, and artistic potential, steel wire mesh has become a favored choice in the entertainment industry for stage backdrops.

- Q: Can steel wire mesh be used for decorative purposes?

- Certainly, decorative purposes can be achieved through the use of steel wire mesh. This highly adaptable material possesses the ability to impart a distinct and contemporary aesthetic to a wide range of environments. By manipulating steel wire mesh into varying shapes and sizes, one can create imaginative and artistic designs. From decorative screens and partitions to wall panels and even sculptures, the possibilities are endless. Moreover, the decorative appeal of steel wire mesh can be further enhanced by applying coatings or paints in an array of colors. Its resilience and strength also render it suitable for outdoor applications, such as fencing and garden features. In conclusion, whether intended for indoor or outdoor utilization, steel wire mesh is undeniably an excellent choice for achieving decorative effects.

- Q: Is steel wire mesh suitable for use in food processing facilities?

- Yes, steel wire mesh is suitable for use in food processing facilities. The use of steel wire mesh in food processing facilities is common due to its various beneficial properties. Firstly, steel wire mesh is a durable and robust material that can withstand the rigorous demands of food processing operations. It is resistant to corrosion, rust, and other forms of degradation, ensuring a long lifespan even in harsh environments. Additionally, steel wire mesh is easy to clean and maintain, which is crucial in food processing facilities where hygiene is of utmost importance. It can be easily sanitized and disinfected, reducing the risk of bacterial contamination and ensuring a safe and clean working environment. Steel wire mesh also offers excellent visibility and ventilation, allowing for proper airflow and preventing the buildup of moisture and condensation. This helps in maintaining the quality and freshness of food products and preventing the growth of mold or bacteria. Furthermore, steel wire mesh is available in various aperture sizes, allowing for customization based on specific requirements. This versatility makes it suitable for a wide range of applications within food processing facilities, such as sieving, filtering, straining, and separating food products. In summary, steel wire mesh is a suitable choice for use in food processing facilities due to its durability, hygiene, visibility, ventilation, and versatility. It provides a reliable and efficient solution for various processes involved in food production, ensuring the safety and quality of food products.

- Q: What is the purpose of using steel wire mesh?

- The utilization of steel wire mesh serves multiple purposes and varies based on its specific application. One primary objective is to offer structural support and reinforcement. In construction projects, steel wire mesh is commonly employed to strengthen concrete structures like walls, columns, and beams. This addition significantly enhances the overall strength and durability of the structure, enabling it to endure greater loads and stresses. Another purpose of steel wire mesh is to serve as a barrier or containment system. It is frequently utilized in fencing and security applications to establish a physical barrier that prevents unauthorized access or delineates boundaries. Steel wire mesh fences are commonly observed in residential, commercial, and industrial settings, providing security and privacy while still allowing visibility and airflow. Moreover, steel wire mesh finds application in filtration and separation processes. Its open and interconnected structure enables effective filtration and separation of solids, liquids, or gases. This makes it ideal for various industrial procedures such as sieving, dewatering, filtering, and particle separation. Steel wire mesh screens are commonly employed in industries such as mining, agriculture, food processing, and pharmaceuticals. Additionally, steel wire mesh serves aesthetic purposes. It can be utilized for decorative purposes in architectural applications, interior design, or artistic installations. Steel wire mesh can introduce texture, visual interest, and a contemporary appearance to spaces, making it a favored option for both functional and decorative objectives. In conclusion, the utilization of steel wire mesh aims to provide strength, reinforcement, security, filtration, and aesthetic appeal across a wide range of applications in diverse industries.

- Q: How does steel wire mesh perform in terms of resistance to high temperatures?

- Steel wire mesh generally performs well in terms of resistance to high temperatures. Steel is a highly durable material that can withstand high temperatures without deforming or melting. The wire mesh's ability to resist high temperatures depends on the type of steel used and the specific manufacturing process. Many steel wire meshes are made from stainless steel, which contains a high percentage of chromium. This chromium content provides excellent heat resistance, making stainless steel wire mesh suitable for applications where high temperatures are encountered. It can withstand temperatures up to 800-1200 degrees Celsius, depending on the specific alloy and grade. Apart from stainless steel, there are other steel alloys that offer even greater heat resistance. For example, Inconel wire mesh is made from a nickel-chromium alloy that can endure extremely high temperatures, up to 1093 degrees Celsius. Inconel wire mesh is commonly used in industries such as aerospace, nuclear, and petrochemical, where extreme heat resistance is required. In addition to the composition of the steel, the construction of the wire mesh also plays a role in its resistance to high temperatures. The mesh's open structure allows for better heat dissipation, preventing excessive heat buildup and reducing the risk of thermal damage. However, it is worth noting that prolonged exposure to high temperatures can still cause some changes in the steel wire mesh's properties, such as a reduction in tensile strength or the development of oxidation. Therefore, it is essential to consider the specific temperature requirements of your application and consult with manufacturers or experts to select the most suitable steel wire mesh for your needs. Overall, steel wire mesh is generally an excellent choice for applications requiring resistance to high temperatures. Its durability, heat resistance, and open structure make it suitable for various industries and environments where thermal performance is crucial.

Send your message to us

Mineral Screen Crimped Wire Mesh

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords