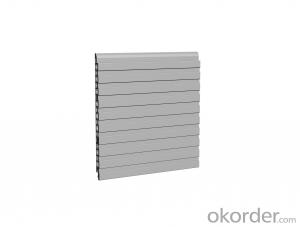

Waterproof Fireproof Wear resistant Interior and exterior walls Fiber Cement Board 4X8

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

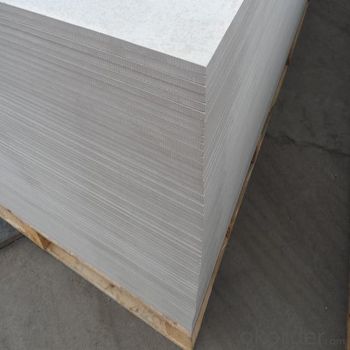

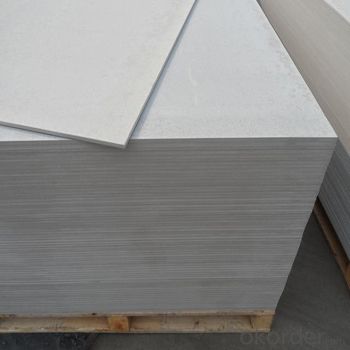

Packaging Details

1.Hold by Wooden Pallet

2.Covered by PVC and Bonded with plastic belt

3.Fasten around the corners

4.Mounted in container to protect your purchasing.

Specification

1. Small board: 595*595mm /600*600mm /603*603mm /595*1195mm /600*1200mm

2. Big board: 1220*2440mm /1220*3050mm

3. Thickness: 4.5, 5, 6, 8, 10, 12, 15, 18, 20, 25mm (4.5-30mm)

Remark: Other specification is available.

Application

application: Partition wall and ceiling

Fireproof structure: Fire Rating Partition, Ceiling, wall, door,

Exterior Cladding and façade structure

Sound Insulation structure

Usage in wet areas

Other purpose: applied to furniture, interlayer floor, interior substrate

Technical Data

Item | Index | Unit | ||

Density | ≤1.20 | g/cm3 | ||

Water contain | ≤10 | % | ||

Water absorption | ≤39 | % | ||

Incombustibility | Grade A1 incombustible | |||

Bending strength | Oven dry | cross | ≥12 | M pa |

Parallel | ≥10 | M pa | ||

Sound and Weather Resistant:

Karmeen fiber cement boards deliver optimal sound and weather insulation. Noise as well as changing weather conditions such as freeze / thaw, heat and water pose no threat to fiber cement board. The boards retain their shape at all times.

Low Maintenance:

The ability of the boards to resist mold and algae attacks is equally impressive. The result is a long-lived façade that saves you time and effort on inconvenient and costly repairs and repaints.

Non-combustible:

The boards are non-combustible, which is your guarantee for a safe building.

Easy Handling:

Karmeen fiber cement boards are flexible and easy to handle. They can be delivered cut to size, ready for installation. All this makes for lower construction costs, shorter construction times, and lower installed costs.

Board Edge:

Fumigation wooden pallets+PE cover + corner protector

- Q: I think I have termites outside on my shield. I sprayed that terminix on the shield but now there are some holes that I want to cover up and since I had extra durock cement board I put it up to help keep any water or anything from going in. Is this a good idea and will the cement board be ok in the weather of the San Jose ca area.

- It will be fine. A bit overkill maybe, but it will work. Might as well use it if you already have it.

- Q: Miyan cement board and wood fiber cement board with the advantages of ordinary cement board

- Wood fiber cement board, the United States rock cement board is mainly created by the Japanese top architect - Ando Takeno advocated the construction of fresh water concrete, the construction of easy operation, ordinary carpentry can be willing to operate the handy.

- Q: pre-tiling bathroom floor

- I would let it set..... or you will warp the cement board as you squish the thin set.

- Q: Will the cement board on the decoration be used to blow it directly?

- If the wall can be placed directly putty putty, putty on the general scraping three times; if the wall is not flat on the first use of plaster gypsum leveling, and then scraping putty.

- Q: I've removed the old cement boards and I've put new ones up on the shower walls. My tile will not go to the ceiling. I'm at the step where I need to apply thin-set and tape to all of the cement board seems. What do I do at the seem that transitions from cement board to sheet rock?

- Use Hardibacker and seal the seams with tape and thinset. Use thinset to set the tile using 1/4 spacers. I have used and recommend that you use a tile sealer to seal the slate prior to grouting and to use epoxy grout. The grout is more difficult to install but requires no sealers which need to be redone at least once a year in a shower and is well worth the initial time and effort. Be sure to read and follow the directions on the grout bags to ensure a uniform color and good grout set. MT C

- Q: Would you recommend putting crazy glue in the draft boards locks, or cement?

- What works best is going in to sign up and fight for your country like a damn man :)

- Q: 5mm cement fiber board how much money a square?

- The price of cement fiberboard is not fixed, and according to the density of the board, the thickness of the gap is very different, usually the conventional board from 6mm-24mm between about 10-37 per square meter

- Q: Do you know that light through the cement? What is the material and how to do it?

- Transparent cement is a widely used with a new light transmission properties of building materials, is composed of fiber and fine grinding cement compounds. The cement is made up of thousands of optical fibers parallel to each other on both sides of the cement block. The proportion of fibers is very low (4%) throughout the cement block. In addition, because the fiber size is very small, so become a cement structure of a collection of components, cement block surface or uniform cement. Transparent cement can be used to build construction installations to build prefabricated blocks and cement boards. As the fiber size is small, so as a new ingredient mixed with the cement together to form a collection. Therefore, the final not only in the cement is mixed with two components of glass fiber only, but in the internal structure and the surface can achieve a balanced effect of new building materials. In theory, the light-permeable cement block can be built with a few meters of thickness of the wall, because the fiber in principle, within 20 meters will not lose any light information. The fiber does not affect the high capacity of the cement, so in these cement blocks can build any load of the building structure. The light-permeable cement block can be produced in a different size, and a heat-insulating layer can be added thereto.

- Q: I'm pulling up the linoleum and replacing it with ceramic tile, 12x12. it's a small bathroom, on the 2nd floor.Under the linoleum is wood. Do i need to lie down cement board before I put the mortar mix down? Or will it be fine to put tiles on the mortar mix on the wood?

- Cement Board Floor

- Q: I'm my history day exhibit board, and I used rubber cement, but the rubber cement stained the background paper I am using. Now, I have to move things around and organize my exhibit, and the stains are showing! How can I get them to go away??? Help!

- Sorry but the stains are there to stay. You might try using some cornmeal or flour and let it set on the stains. They might pull some of the oily residue out of the paper but it won't take it all out. You might have to paint over the stains.

Send your message to us

Waterproof Fireproof Wear resistant Interior and exterior walls Fiber Cement Board 4X8

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords