EPDM Membrane Vulcanization Thickness 1.2MM for Waterproof System

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

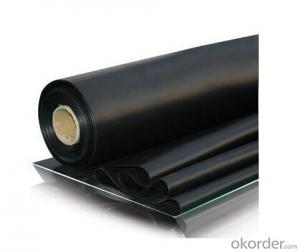

EPDM Membrane Vulcanization 1.2 mmfor Waterproof System

Description Of EPDM Membrane Vulcanization1.2 mm:

1. EPDM 1.2 mm membrane is made from ternary ethylene-propylene rubber, which is for waterproofing of exposed and non-exposed applications.

2. EPDM 1.2 mm membrane production adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization technology.

3. EPDM 1.2 mm is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

Main Features of EPDM Vulcanization EPDM Membrane1.2 mm:

1. Excellent physical and mechanical performance

2. High tearing resistance

3. Good deformation adaptability

4. High puncture resistance

5. High aging resistance

6. UV resistance

Specifications of EPDM Vulcanization Membrane1.2 mm:

Material | Ternary Ethylene-Propylene rubber |

Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

Thick | 1.2mm, 1.5mm, 2.0mm |

Type | Vulcanized |

Pattern | Non-reinforced (homogeneous) |

Certificate | ISO9001/14001 |

Applications of EPDM Rubber Waterproof Membrane1.2 mm:

1.Roofs, Basement, Toilets

2. Industrial and civil building waterproofing

3. Geosynthetic liner for swimming pool, channels, irrigation system

4. Especially suitable for projects with high requirements in durability, anti-corrosion and deformation.

IMages of EPDM Vulcanization Membrane:

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

.

2. How Many years experience do we have?

We have been exported to more than 15 countries in the past 10 years.

3. How long do we usually reply your request?

We always reply our customer within 12 hours.

- Q: Can a waterproofing membrane be used on tunnels?

- Yes, a waterproofing membrane can be used on tunnels. Tunnels are often subjected to high levels of moisture, groundwater infiltration, and potential leaks. Therefore, it is crucial to protect them from water damage and ensure their long-term structural integrity. Waterproofing membranes are commonly used in tunnel construction to prevent water penetration and provide an effective barrier against moisture. These membranes are designed to be durable, flexible, and resistant to various environmental conditions, making them suitable for use in tunnels. They can be applied to the tunnel walls, roof, and floor to create a waterproof seal, ensuring that the tunnel remains dry and protected from water-related issues such as corrosion, deterioration, and mold growth. Additionally, waterproofing membranes can also help in reducing maintenance costs and extending the lifespan of the tunnel infrastructure.

- Q: Can a waterproofing membrane be exposed to extreme temperatures?

- Yes, a waterproofing membrane can generally be exposed to extreme temperatures. Most waterproofing membranes are designed to withstand a wide range of temperatures, including both high and low extremes. However, it is important to note that the specific temperature limits and performance characteristics may vary depending on the type and brand of the membrane. It is always recommended to consult the manufacturer's specifications and guidelines to ensure the membrane is suitable for the specific temperature conditions it will be exposed to. Additionally, it is important to consider other factors such as UV exposure and thermal expansion/contraction that may affect the overall performance and longevity of the waterproofing membrane in extreme temperature conditions.

- Q: Can a waterproofing membrane be used in areas with high groundwater levels?

- Certainly, it is possible to utilize a waterproofing membrane in regions with elevated groundwater levels. In truth, it is strongly advised to employ a waterproofing membrane in such areas to safeguard the integrity of the edifice from water penetration. The primary purpose of a waterproofing membrane is to construct a barrier that hinders the ingress of water into the building or structure. This becomes particularly crucial in zones with high groundwater levels due to the substantial pressure exerted by the water, which heightens the chances of water damage or flooding. By implementing a waterproofing membrane, you can effectively minimize the risk of water infiltration and ensure the long-lasting resilience of the structure.

- Q: Can a waterproofing membrane be applied to concrete surfaces?

- Yes, a waterproofing membrane can be applied to concrete surfaces.

- Q: Can a waterproofing membrane be used in new construction?

- Yes, a waterproofing membrane can be used in new construction. In fact, it is often recommended to install a waterproofing membrane during the construction phase to prevent water damage to the building's foundation and structure.

- Q: Can a waterproofing membrane be used on brick walls?

- Yes, a waterproofing membrane can be used on brick walls. It helps to prevent water penetration and protects the bricks from moisture damage.

- Q: What is the difference between PET waterproofing membrane and BAC waterproofing membrane? What is the commonality? Is BAC a PET?

- PET refers to polyethylene terephthalate, PET film using polyester composite film as the surface material, coated with rubber asphalt adhesive material, with cement mortar paste or self-adhesive. Can be constructed on the wet base surface, the grass-roots requirements are low, with high bond strength, bonding effect is good, not channeling water and so on.

- Q: Can a waterproofing membrane be used for a shower enclosure?

- Indeed, it is possible to utilize a waterproofing membrane for the purpose of a shower enclosure. Waterproofing membranes possess the capability to impede the infiltration of water through various surfaces, consequently preventing any potential harm. Within a shower enclosure, where water exposure is exceedingly pronounced, application of a waterproofing membrane on both the walls and floor is highly advisable in order to establish a safeguarding barrier. This measure serves the purpose of guaranteeing that water does not permeate the encompassing structure, thereby averting predicaments such as mold proliferation, decay, and water-induced impairment. To attain optimal outcomes, it is crucial to opt for a waterproofing membrane specifically tailored for showers and adhere to the manufacturer's guidelines for accurate installation.

- Q: Can a waterproofing membrane be used for parking garages?

- Yes, a waterproofing membrane can be used for parking garages. Waterproofing membranes are commonly used in construction to prevent water infiltration and damage to structures. Given the potential exposure of parking garages to water from rainfall, snowmelt, or vehicle fluids, using a waterproofing membrane can help protect the structural integrity of the garage and extend its lifespan.

- Q: Are there any special tools required for installing a waterproofing membrane?

- Yes, there are several special tools required for installing a waterproofing membrane. These tools may vary depending on the specific type of membrane being installed, but some common tools include a trowel or brush for applying the membrane, a utility knife for cutting the membrane to size, a roller for ensuring proper adhesion, and a heat gun for activating any adhesive properties of the membrane. Additionally, other tools such as a measuring tape, level, and caulking gun may be necessary for proper installation. It is important to consult the manufacturer's instructions and recommendations to ensure that the correct tools are used for the specific membrane being installed.

Send your message to us

EPDM Membrane Vulcanization Thickness 1.2MM for Waterproof System

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords