Vokes® NPP Fumed Silica Nanoporous Insulation Panel - High Temperature Microporous Insulating Fire Brick

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CHARACTERISTICS:

Vokes®NNP is a micro porous thermal insulating panel with excellent insulating properties. The core material of Vokes® NPP is fumed silica which is made by nano technology. Furthermore an infrared opacifier is added to minimize thermal transmission by in heat radiation. It’s noncombustible, specializes in the insulation applications where the space is limited but a high thermal resistance is necessary. Long-term application temperature is during -120℃-1000℃, the insulation performance is much better than the traditional materials, especially at high temperature.

ADVANTAGES:

• Wide insulation range: Long-term working temperature is at the period of -120℃-1000℃.

• Extremely low and stable thermal conductivity: At normal temperature, the insulated performance is at least 3-5 times better than the traditional materials. At temperatures higher than 300℃, the insulated performance is at least 4-8 times better than the traditional materials.

• Space saving: It drastically reduced insulation thickness.

• Easy installation and maintenance: The small density makes installing safely and easily.

•Corrosion resistant: Products are made of inorganic silicates, it doesn’t include soluble chloride ions, won’t cause corrosion on equipments, pipes..

• Soundproof/Shockproof: It helps acoustic noise reduction and shock buffer.

• Waterproof: Nano particles of product themselves are super hydrophobic.

• Durable: It has a long working life.

APPLICATIONS:

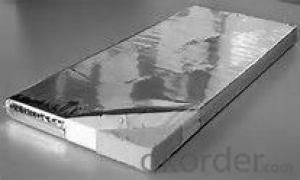

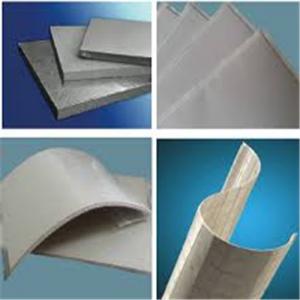

Vokes®NNP is widely used because of the stable thermal performance. According to diverse situations, Vokes®NNP can be protected with appropriate covers.

-Industrial furnace (rotary kiln, shuttle kiln, steel ladle, tundish, oven door etc. )

-Metallurgical industry (steel, aluminum, smelting furnace, holding furnace, etc.)

-Instrument (temperature tracker, heat receiver, date protection system, etc.)

-Oil and energy (piping, reacting furnace, etc.)

-Refrigeration and freezing

-Automotive (Cars, trains, planes, ships, etc.)

PRODUCT DATA:

Surface color: White/Grey

Geometry:Rectangular shape (without protruding flanges*)

Density ≤300kg/m³

Thermal conductivity (Surface temperature:℃)

50℃ 0.016W/(m·k)

200℃ 0.020W/(m·k)

300℃ 0.023W/(m·k)

400℃ 0.025W/(m·k)

500℃ 0.033W/(m·k)

600℃ 0.040W/(m·k)

700℃ 0.049W/(m·k)

800℃ 0.060W/(m·k)

900℃ 0.064W/(m·k)

1000℃ 0.073W/(m·k)

Refractoriness: 1300℃

Cold Crushing Strength (Compression 20%) ≥0.40MPa

Permanent Linear Change(800℃×24h) ≤1.0%

Standard dimension (L x W)(mm): 1200x600/500x600/250x600

Thickness:10mm/15mm/20mm/25mm/30mm/40mm/50mm

Size tolerance • 0 to 500 mm: ±2 mm

Thickness tolerance: ± 1 mm

Service life : extrapolated, depending on application up to 50 years.

- Q: Can insulating fire bricks be used in the construction of glass fusing kilns?

- Yes, insulating fire bricks can be used in the construction of glass fusing kilns. These bricks have excellent insulating properties, which helps in maintaining consistent and controlled temperatures inside the kiln. Additionally, they can withstand high temperatures without cracking or breaking, making them suitable for glass fusing kilns.

- Q: Are insulating fire bricks resistant to abrasion or erosion?

- Insulating fire bricks are generally not resistant to abrasion or erosion. While they are excellent at insulating heat, they are typically made from materials that are not designed to withstand high levels of wear and tear. Insulating fire bricks are often used in applications where they are not exposed to significant mechanical forces or abrasive materials. If abrasion or erosion is a concern, a different type of refractory material or lining may be more suitable for the specific application.

- Q: Are insulating fire bricks resistant to high-velocity gas flow erosion?

- Insulating fire bricks are generally capable of resisting erosion caused by high-velocity gas flow. These bricks are engineered to endure extreme temperatures and harsh conditions, including environments prone to erosion. They are crafted from top-notch refractory materials, like alumina and silica, renowned for their outstanding resistance to erosion and corrosion. Moreover, insulating fire bricks possess low thermal conductivity, aiding in minimizing heat loss and preserving their structural integrity even when subjected to high-velocity gas flow. Nonetheless, it is crucial to acknowledge that the precise level of resistance may differ depending on the unique composition and manufacturing techniques employed in creating the insulating fire bricks.

- Q: Can insulating fire bricks be used for insulation in cement kilns?

- Insulation in cement kilns can be achieved by using insulating fire bricks. These bricks are made from lightweight materials like ceramic fibers or expanded clay, which possess high insulation properties. Their low thermal conductivity allows them to effectively reduce heat transfer and retain heat within the kiln. Cement kilns operate at extremely high temperatures, often surpassing 1,400 degrees Celsius (2,500 degrees Fahrenheit). Incorporating insulating fire bricks in the kiln helps prevent heat loss, enhances energy efficiency, and reduces fuel consumption. By creating a barrier between the hot gases inside the kiln and the surrounding environment, these bricks minimize heat escape. Additionally, insulating fire bricks exhibit remarkable resistance to thermal shocks, enabling them to withstand the severe temperature fluctuations that occur in cement kilns. This durability ensures long-lasting insulation, minimizing the need for frequent maintenance and replacement. Nevertheless, it is crucial to note that the specific type and composition of insulating fire bricks required for cement kiln insulation may vary depending on factors such as the kiln's design and operating conditions. Consulting with experts or manufacturers specializing in refractory materials is advisable to ensure the correct selection and installation of insulating fire bricks for cement kiln insulation.

- Q: Can insulating fire bricks be used in the construction of pottery slab rollers?

- Yes, insulating fire bricks can be used in the construction of pottery slab rollers. These bricks can provide thermal insulation and withstand high temperatures, making them suitable for pottery kilns and other heat-intensive applications like slab rollers.

- Q: Are insulating fire bricks suitable for use in the construction of incinerators?

- Yes, insulating fire bricks are suitable for use in the construction of incinerators. Insulating fire bricks have excellent thermal insulation properties, allowing them to withstand high temperatures and efficiently retain heat. This makes them ideal for lining the walls and floors of incinerators, as they help to contain and direct heat, ensuring proper combustion while reducing heat loss. Additionally, insulating fire bricks are resistant to chemical attacks and can withstand the corrosive environment found in incinerators, making them a reliable choice for this application.

- Q: How do insulating fire bricks affect the overall energy consumption of a building?

- Insulating fire bricks can significantly impact the overall energy consumption of a building in a positive way. These bricks are designed to have high thermal resistance, which means they are effective in reducing heat transfer between the inside and outside of a building. By using insulating fire bricks in the construction of walls, floors, and ceilings, the building becomes better insulated, resulting in reduced heat loss during the colder months and decreased heat gain during the hotter months. This improved insulation helps maintain a more comfortable temperature inside the building, reducing the need for excessive heating or cooling. When a building is properly insulated with fire bricks, the HVAC system doesn't have to work as hard to maintain the desired temperature, resulting in lower energy consumption and reduced utility bills. Additionally, the reduced energy demand also has a positive environmental impact by reducing greenhouse gas emissions associated with energy production. In addition to their thermal insulation properties, insulating fire bricks also offer excellent fire resistance. This can enhance the safety of the building by limiting the spread of fires and providing additional time for occupants to evacuate. This fire resistance can potentially lower insurance costs for the building. Overall, insulating fire bricks play a crucial role in reducing energy consumption and improving energy efficiency in buildings. They not only provide cost savings for the building owners but also contribute to a more sustainable and eco-friendly environment.

- Q: Can insulating fire bricks be used in refractory linings for blast furnaces?

- Yes, refractory linings for blast furnaces can utilize insulating fire bricks. These bricks are specifically designed to possess low thermal conductivity, effectively minimizing heat loss from the furnace. This characteristic holds particular significance in blast furnaces where maintaining high temperatures is crucial for optimal operation. Insulating fire bricks are crafted from lightweight refractory materials like alumina or silica, renowned for their exceptional insulating properties. These bricks not only provide thermal insulation, but they also exhibit remarkable resistance to thermal shock, rendering them suitable for the extreme conditions prevalent in blast furnaces. Beyond insulation, insulating fire bricks present additional advantages for blast furnace linings. They possess a lightweight nature and are easily installable, thereby reducing construction labor and time requirements. Moreover, their low thermal conductivity aids in minimizing the occurrence of hot spots and uneven temperature distribution within the furnace. These issues, if unaddressed, can trigger premature wear and failure of the refractory lining. However, it is crucial to acknowledge that relying solely on insulating fire bricks may not suffice for all portions of the blast furnace lining. Certain areas, such as the hearth and tuyere zones, may necessitate high-density refractory bricks capable of withstanding intense heat and mechanical stress. In such cases, a combination of insulating fire bricks and other refractory materials can be employed to achieve the desired performance and longevity. Overall, insulating fire bricks serve as a valuable constituent in refractory linings for blast furnaces, offering benefits such as enhanced energy efficiency, reduced heat loss, and prolonged lifespan of the lining.

- Q: Are insulating fire bricks suitable for use in kilns and furnaces?

- Yes, insulating fire bricks are suitable for use in kilns and furnaces. Insulating fire bricks are designed to provide excellent thermal insulation, making them ideal for applications that require high temperatures, such as in kilns and furnaces. They have low thermal conductivity which helps to minimize heat loss and improve energy efficiency. Additionally, insulating fire bricks are lightweight and durable, allowing for easy installation and long-lasting performance in high-temperature environments. They are resistant to thermal shock and can withstand rapid temperature changes, making them a reliable choice for kilns and furnaces. Overall, insulating fire bricks are an excellent option for providing insulation and maintaining high temperatures in kilns and furnaces.

- Q: What is the exterior wall insulation material made of graphite?

- Graphite is polystyrene board, polyurethane graphite plate, from the point of view of building the acceptance specification in the use process, the core index of insulation material is the heat transfer coefficient and safety, by now a large number of glazed hollow bead slurry from the actual situation it seems difficult to ensure the quality of construction materials should be on site workers slurry mixing, finished product the quality gap made out of very large.

Send your message to us

Vokes® NPP Fumed Silica Nanoporous Insulation Panel - High Temperature Microporous Insulating Fire Brick

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords