Vokes® VIP Boards - Fumed Silica VIPs for Building and Industrial Applications

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

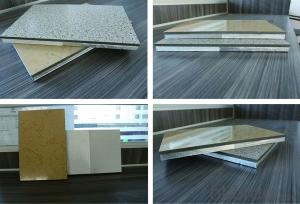

Vokes® VIP (Vacuum insulation panels)

Characteristics

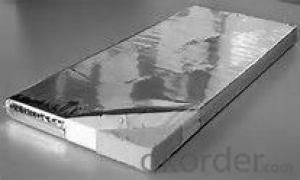

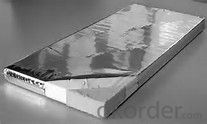

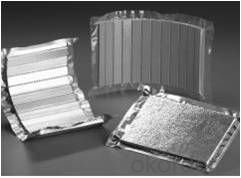

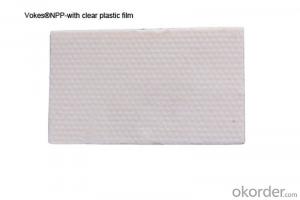

Vokes® VIP is an evacuated micro porous thermal insulating panel

with excellent insulating properties. Vokes® VIP

The core material of Vokes® VIP is fumed

Silica board and noncombustible. It is sealed into a high gas barrier

film under vacuum. Vokes® VIP

Application

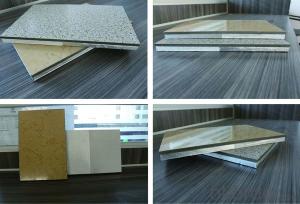

Vokes® VIP is specially developed for insulation applications where

not much space is available but a high thermal resistance is necessary.

Vokes® VIP

Vokes® VIP is a successful insulation element in the following areas:

• Building appl ication (Roofs, floors, etc)

• Thermal packaging (Medicine trnasport boxes, etc.)

• Appliance (Water boiler, etc.)

• Automotive (train, ship, air plains, etc.)

Advantage

• Drastically reduced heat fluxes

• Drastically reduced insulation thickness

• Increased usable volume

• All purpose VIP with a long service life

Product data

Surface color Silver

Geometry Rectangular shape (without protruding flanges*)

Density 180 to 210 kg/m³

Thermal conductivity < 0.004 W/mK

Temperature stability -70 °C to +70 °C (due to the film)

Thermal shock resistance Not sensitive to heat & cold shock in the given

temperature range

Humidity stability 0 % to 60 %

Internal gas pressure 1 mbar (at delivery)

Increase of gas pressure approx. 1 mbar/year (at 20 mm thickness &

normal room conditions)

Standard dimension (L x W)(mm) 100x400/200 x600/400 x600/600 x1000/600 x1200

Thickness 10mm/15 mm/20 mm/25mm/30mm

Size tolerance

• 0 to 500 mm ±2 mm

Thickness tolerance ± 1 mm

Specific heat capacity 0.8 kJ/(kg·K) (at normal room temperature)

U-value U 0.2 W/(m²K) (at 20 mm thickness)

Mass per area 4 kg/m² (at 20 mm thickness)

Compressive strengh GB8813/EN8268- ≥0.15MPa

Flammability GBB624- A

Service life extrapolated, depending on application up to 50

years

- Q: I ask, our home is the top floor, the summer is too hot, the walls and roof in addition to the use of insulation board, posted their own kind of tin foil, will not be useful?

- At present, the domestic brand is not clear who is using a good insulation board should be made of silica filler, because the BET for the nano-so the effect is better. Energy saving can reach more than 30 percent

- Q: Is the thermal conductivity of the vacuum insulated plate used to protect the hot plate method?

- Mainly in the 40 yuan / m or so, but the specific price depends on color steel sandwich panel core material and specifications to determine the model

- Q: What brand of refrigerator is using a vacuum insulation board? What kind of insulation board is better? More

- What do you mean if you want to get your own steel pipe fastener? Which city is in the city?

- Q: What is the best insulation material? To be waterproof.

- Under normal circumstances, the steel structure of the plant panel can be a single laminated steel plate, double laminated steel plate, composite color plate. Single-layer steel plate used for simple plant or temporary plant roof, this material is affordable, but the insulation effect is poor, easy to leak. Double laminated steel plate effect will be better. Composite color steel plate for the use of insulation materials sandwich practice, insulation and noise effects are very good, but as a roof, the national standard requires sandwich material must be flame retardant or non-combustible materials.

- Q: External wall insulation material which is good, external wall insulation materials

- Indoor insulation material that the best, fire, environmental protection, good insulation effect? ??Glass fiber. Good insulation. Glass fiber cotton with numerous fine gas holes, fibers arranged irregularly arranged, heat conduction breakdown of 0.03w / cm.k, is an excellent insulation material; . with non-flammable. Glass fiber cotton will not burn, no deformation, no embrittlement, can withstand 700 degrees of high temperature, the combustion performance to A1; . environmental non-toxic. As the glass fiber cotton in the manufacturing process does not add any adhesive, so there is no smell, high temperature will not be distributed when the toxic, pungent smell, smell, etc .; . high insulation. As the glass fiber cotton used in the raw material is glass, non-conductive, so it has a very high insulation; . corrosion resistance. Glass fiber is not afraid of strong acid, with a strong corrosion resistance, even if the use of long time will not reduce its functional characteristics; . good recovery Glass fiber contains numerous fixed cavitation, with excellent recovery, not afraid of any shock, tensile strength are more than 1.0kg; . do not want to light field scrambled decanoate containing mutual water. The moisture absorption of glass fibers is usually close to zero, do not worry about there will be water swelling caused by wet cracking of the situation. I hope my answer can help you.

Send your message to us

Vokes® VIP Boards - Fumed Silica VIPs for Building and Industrial Applications

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords