Vokes® NPP (Nanoporous insulation panels)

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Vokes® NPP (Nanoporous insulation panels)

Characteristics

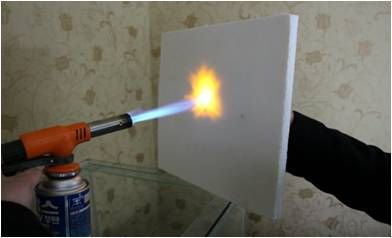

Vokes® NPP is an evacuated micro porous thermal

insulating panel with excellent insulating properties.

Vokes® NPP

The core material of

Vokes® NPP is fumed Silica board and noncombustible.

It is sealed into a high gas barrier film under vacuum.

Vokes® NPP

Application

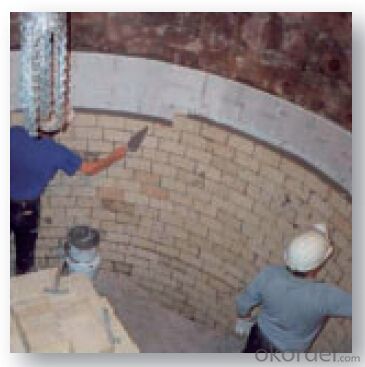

Vokes® NPP is specially developed for insulation

applications where not much space is available but a

high thermal resistance is necessary. Mainly used in

high-temperature insulationMainly used in hightemperature

insulation.

Vokes® NPP

Vokes® NPP is a successful insulation element in the following areas:

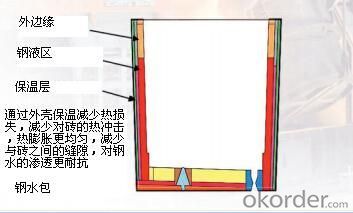

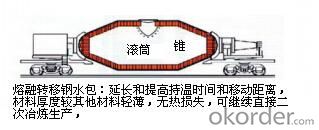

• Industrial equipment insulation

• High temperature boiler insulation

• Thermal packaging (Medicine transport boxes, etc.)

• Appliance (Water boiler, etc.)

• Automotive (train, ship, air plains, etc.)

Advantage

• Insulation : Long-term application temperature reached -120℃-1200℃. Insulation at normal

temperature for 3-5 times the performance of traditional materials. Stable thermal conductivity at high

temperatures, Temperature at 300 ℃ insulation performance is 4-8 times that of traditional materials.

• Drastically reduced insulation thickness

• Thermal resistance :Particles constituting unit having a three-dimensional network structure,

will form many nanoporosity avoid sintering deformation.

• All purpose VIP with a long service life

•Corrosion resistant :Products made of an inorganic material, no soluble chloride ions, No

corrosion on equipment, pipe grassroots.

• Soundproofing/Seismic Performance :Acoustic noise reduction, buffer shock.

• Waterproof :Product nanoparticles themselves with super hydrophobic properties.

Product data

Surface color whiter

Geometry

Rectangular shape (without protruding

flanges*)

Density ≤300kg/m³

Thermal conductivity (Surface

temperature:℃)

50 0.016W/(m·k)

200 0.020W/(m·k)

300 0.023W/(m·k)

400 0.025W/(m·k)

500 0.033W/(m·k)

600 0.040W/(m·k)

700 0.050W/(m·k)

800 0.060W/(m·k)

Refractoriness >1200℃

cold crushing strength

(Compression 20%) ≥0.40MPa

permanent change in dimension on heating

(800℃×24h) ≤1.0%

Standard dimension (L x W)(mm) 250x600/500x600/1200x600

Thickness

10mm/15 mm/20

mm/25mm/30mm/40mm/50mm

Size tolerance

• 0 to 500 mm ±2 mm

Thickness tolerance ± 1 mm

Service life : extrapolated, depending on application up to 50.

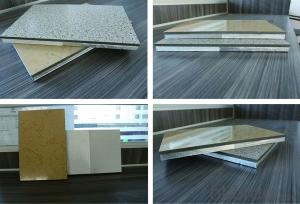

Vokes® NPP Nanoporous insulation panel for industrial applications

Vokes® NPP surface can be a composite various materials(Heat shrinkable film, Glass fiber cloth,

- Q: Detailed description of the feed pump

- At this point, 0.9Mpa decompression to 0.2Mpa throttle pressure loss, there is a significant energy loss.

- Q: 15KW of the induced draft fan is about how much?

- Ventilators are widely used for ventilation, dust and cooling in factories, mines, tunnels, cooling towers, vehicles, ships and buildings; ventilation and induced winds for boilers and industrial furnaces; air conditioning and household appliances cooling and

- Q: What material is used for the fan

- Gas compression and gas transport machinery is the conversion of mechanical energy into gas pressure energy and kinetic energy, and the gas transported out of the machinery.

- Q: What is the history of the blower?

- The image of the canyon pedal has been painted in the murals of the tombs of the 18th dynasty of Rekhmir (about 1450 BC).

- Q: There is no difference between the blower and the blower

- The working principle of a centrifugal blower is similar to that of a centrifugal fan, except that the compression process of the air is usually carried out by centrifugal forces after several working impellers (or stages).

- Q: What is the blower to open the blower?

- (6) Place a container underneath the engine, below the water supply pipe behind the cylinder head.

- Q: Energy saving of wind turbines

- Today, all walks of life in various industries and machinery and electrical equipment and fans supporting the motor about 60% of the installed capacity of the country, the consumption of electricity accounts for about one-third of the total power generation.

- Q: The relationship between fan power and air flow

- The amount of air flowing per unit of time is used to indicate the capacity of the blower or ventilation equipment, calculated in cubic meters per second.

- Q: What is the main difference between a ventilator and a draft fan?

- And our daily, and the fan according to positive and negative pressure when used, divided into:

- Q: What is the difference between a high-pressure ring fan and a Roots blower?

- The air between the impeller blades is spirally accelerated and the gas outside the pump body is squeezed into the side slot (when sucked into the side of the suction port). When it enters the side channel, the gas is compressed and then reverts between the impeller blades

Send your message to us

Vokes® NPP (Nanoporous insulation panels)

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot Searches

Related keywords