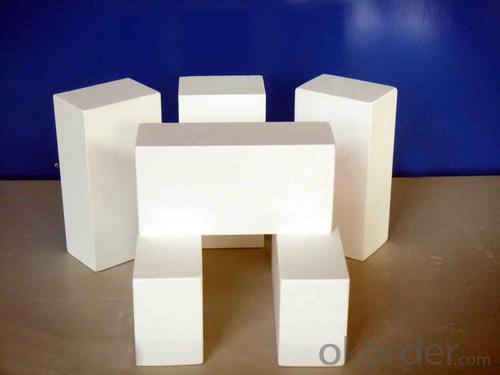

Insulating Fire Brick - DJM 26 Lightweight

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Thermal Insulation Fire Clay Brick

DJM 26 Light Weight Insulating fire brickconforms strictly to the requirements of ISO 9000 quality control system during the production. MSDS is also available if you want. The thermal insulation fire clay brick meet with the requirements of ASTM & JIS standards. So please stay cool with our quality.

Application

DJM 26 Light Weight Insulating fire brick are used for the lining of converter, alternating current arc furnace, direct Current arc furnace and the ladle slag line, etc.

Company Advantage

(1)Long Insulating Fire Brick manufacture history: 25 years manufacturer

(2)Advanced equipment

(3)Diversification of production standards: ISO ANSI FEPA JIS ASTM

(4)Flexible payment: T/T L/C D/P D/A

(5)Professional marketing team and after-sale service

(6)Free sample

Equipment

1 unit of Ceramic Abrasive (SG Abrasive) pilot production line

1 unit of high-end coated abrasives (abrasive cloth) production line

2 units of Boron Carbide production lines

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: What is the weight of an average insulating fire brick?

- The size and composition of an average insulating fire brick can cause its weight to differ. On average, these bricks weigh around 2.5 to 5 pounds (1.13 to 2.27 kilograms). They are specifically engineered to be lightweight, enabling effortless handling and installation in different thermal insulation applications.

- Q: Can insulating fire bricks be used in the construction of industrial chimneys?

- Indeed, insulating fire bricks are capable of being utilized in the construction of industrial chimneys. These bricks are meticulously crafted with exceptional thermal insulation properties, rendering them perfectly suited for situations where precise temperature management is paramount. Given that industrial chimneys endure elevated temperatures and heat transmission, insulating fire bricks prove invaluable in mitigating heat dissipation or acquisition, thereby enhancing energy efficiency and minimizing the likelihood of structural harm. Furthermore, these bricks exhibit commendable resilience against thermal shock, enabling them to endure the rigorous conditions commonly encountered in industrial environments. Consequently, insulating fire bricks emerge as a fitting choice for constructing industrial chimneys.

- Q: Are insulating fire bricks resistant to erosion?

- Insulating fire bricks, in general, exhibit resistance to erosion. They consist of lightweight materials like alumina, silica, or a combination thereof. These materials possess remarkable resistance to erosion caused by elevated temperatures, chemical reactions, and physical wear. They are engineered to endure extreme heat and harsh circumstances, rendering them highly resistant to erosion. Furthermore, insulating fire bricks demonstrate low thermal conductivity, preventing easy absorption or transfer of heat and thereby affording additional protection against erosion. Nevertheless, it is worth noting that the level of erosion resistance may differ depending on the precise composition and quality of the insulating fire bricks.

- Q: The insulation layer destroyed after use of cement paste and tiling

- Put on the insulating layer and paste it with cement.Some students worry about the insulation layer and the wall adhesive strength is not enough, do not worry about, now developers are building exterior insulation and then on top of the tiling. Because after finishing the insulation layer, the contractor should check the construction to do a pullout test, the purpose is to prevent the strength can not meet the requirements.

- Q: Are insulating fire bricks resistant to impact or mechanical stress?

- Indeed, insulating fire bricks exhibit resistance against impact and mechanical stress. These bricks are crafted using lightweight refractory materials, purposefully formulated to endure extreme temperatures and thermal shock. Their composition is specifically engineered to possess exceptional resilience against mechanical stress and impact, rendering them appropriate for a multitude of applications in which external forces or pressure may be exerted upon them. Remarkably, these bricks retain their structural integrity and durability, safeguarding their shape and thermal insulation attributes even when subjected to mechanical stress or impact. Consequently, they are highly recommended for deployment in furnaces, kilns, and other environments characterized by elevated temperatures.

- Q: Do insulating fire bricks have good mechanical strength?

- Yes, insulating fire bricks have good mechanical strength. They are specifically designed to withstand high temperatures and provide excellent thermal insulation while maintaining their structural integrity.

- Q: Do insulating fire bricks have a high thermal shock resistance?

- Insulating fire bricks are commonly known for their remarkable thermal shock resistance. They are specifically engineered to endure sudden temperature variations without any fractures or damage. Crafted from lightweight refractory materials with low thermal conductivity, these bricks effectively reduce heat transfer and prevent thermal strain. Furthermore, the firing process they undergo further enhances their ability to withstand thermal shocks. In summary, these bricks are perfect for situations where extreme temperature fluctuations are encountered, making them a dependable option for insulation in high-temperature surroundings.

- Q: Can insulating fire bricks be used in ceramic fiber boards?

- Insulating fire bricks have the potential to be utilized in ceramic fiber boards. They are commonly employed as a lining material for high-temperature purposes due to their ability to endure extremely high temperatures and offer exceptional thermal insulation. Conversely, ceramic fiber boards are lightweight and possess commendable thermal shock resistance, rendering them suitable for employment in diverse industrial and residential settings. When utilized in conjunction, insulating fire bricks can be positioned behind or around the ceramic fiber boards to augment their insulating properties and elevate overall thermal efficiency. The bricks have the capability to provide additional structural support and assist in retaining heat within the system, thereby enhancing energy efficiency and minimizing heat loss. Nevertheless, it is crucial to acknowledge that the compatibility of insulating fire bricks and ceramic fiber boards might fluctuate based on the specific application and requirements. It is advisable to seek guidance from manufacturers or industry professionals to ensure appropriate selection and installation of these materials according to your individual needs.

- Q: Are insulating fire bricks porous?

- Yes, insulating fire bricks are porous.

- Q: What is the lifespan of insulating fire bricks?

- The lifespan of insulating fire bricks can vary depending on various factors. Typically, these bricks are designed to be long-lasting and can endure for numerous years or even decades if correctly installed and maintained. The longevity of insulating fire bricks is significantly influenced by their quality. Superior materials and manufacturing processes used in the production of high-quality bricks tend to result in a longer lifespan compared to lower-quality bricks. It is important to select bricks from reputable manufacturers who abide by stringent quality control standards. The application and conditions under which insulating fire bricks are used also play a crucial role. If exposed to extreme temperatures, such as in furnaces or kilns, the bricks may undergo thermal shock and degradation over time. Similarly, exposure to corrosive chemicals or abrasive materials can also impact the bricks' lifespan. To maximize the lifespan of insulating fire bricks, proper installation and maintenance are essential. They should be installed in accordance with the manufacturer's guidelines, ensuring proper alignment and support. Regular inspections should be carried out to detect any signs of damage or wear, with prompt repairs or replacements made as necessary. In conclusion, while the exact lifespan of insulating fire bricks cannot be determined with absolute certainty, it is reasonable to expect them to endure for several years to several decades when used in suitable applications and maintained appropriately.

Send your message to us

Insulating Fire Brick - DJM 26 Lightweight

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords