VIP Boards Micropores Insulation Fireproof Board for Fire Elevator

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for Micropores Insulation Fireproof Board for Fire Elevator

| Place of Origin: | China | Brand Name: | CMAX | Model Number: | micropores insulation board |

| Material: | PTFE | Thickness: | 3mm-100mm, 3mm-100mm | Size: | Length & Width: 500mm*500mm,600mm*600mm,1000mm*1000mm,1200mm*1200mm |

| Certificate: | ISO9001:2000,ISO9001:2008 | Coating: | alumina foil/ glass fiber cloth | Length & Width: | 500mm*500mm,600mm*600mm,1000mm*1000mm,1200mm*1200mm |

| Grade: | A grade (100% virgin), B grade (50% virgin), C grade ( 30% virgin) | Polytetrafluoroethylene: | PTFE,also named TEFLON. | Characteristics: | includes molded sheet and skived sheet |

| Applications: | used within -180℃~+260℃ | Delivery: | 7 days after the receipt of the deposit | Packaging: | Pallet or according to customer requirement |

Packaging & Delivery

| Packaging Details: | 1.Paper-carton with polybag inside. 2.Paper-carton with polybag inside snd pallet. 3.Paper-carton with polybag inside and shrinkable film and strapped. |

| Delivery Detail: | 15 Days |

1.Micropores Insulation Fireproof Board for VDR (Voyage Data Recorder) / aluminium/Power/Cement/Nonferrous/steel industry.

Microporous Insulation Boards are specially designed for steel industry & metallurgy with very good thermal and mechanical properties. The formulation is an opacified blend of filament reinforced pyrogenic silica. The coverings is water repellent to assure the stability of the microporous insulation boards when moisture may occur due to castables, mortar etc.

Micropore Insulation Boards can be as much as four times more effective than conventional insulation materials. In practical terms this means that a Micropore Insulation Boards system can be only one quarter of the thickness for equivalent thermal control. This becomes crucially important wherever space is limited.

Typical Applications

Back-up insulation in industrial furnaces

Fuel cells (SOFC)

Thermal Batteries

Aluminium industry ( launders,Smelter.etc. )

Glass & ceramics industry

Petrochemical industry (cracking furnace, reformer)

Black box & VDR (Voyage Data Recorder)

Data loggers

Properties & Advantages

Extremely low thermal conductivity

High thermal stability

High compressive strength

No harmful respirable fibres

Free of organic binders

Environmentally friendly

Resistant to most chemicals

Non combustible

Easy to handle

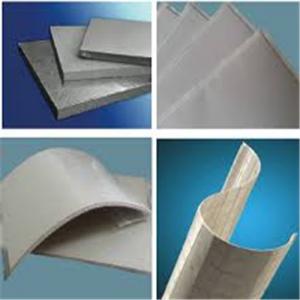

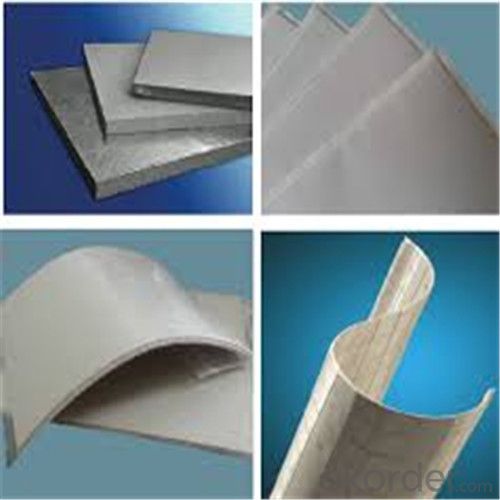

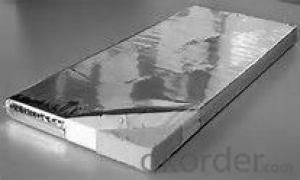

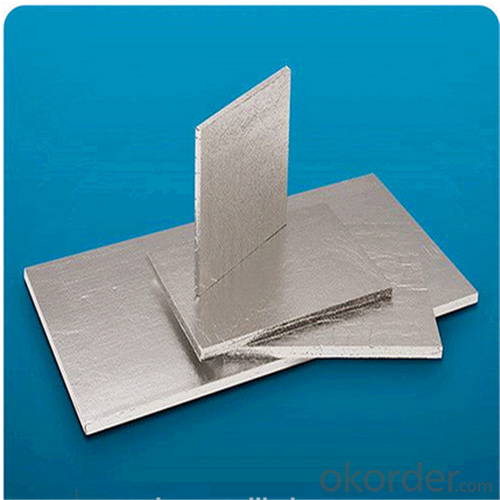

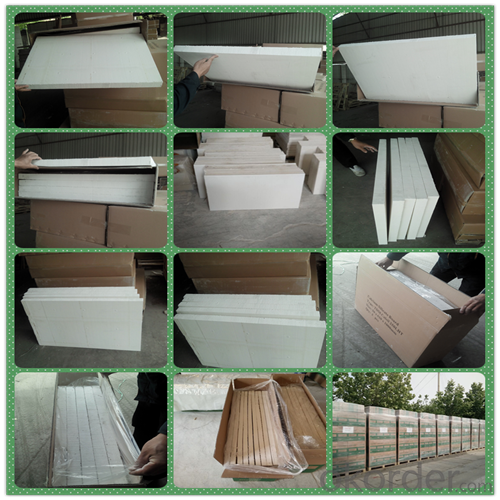

2.Pictures of micropores insulation board

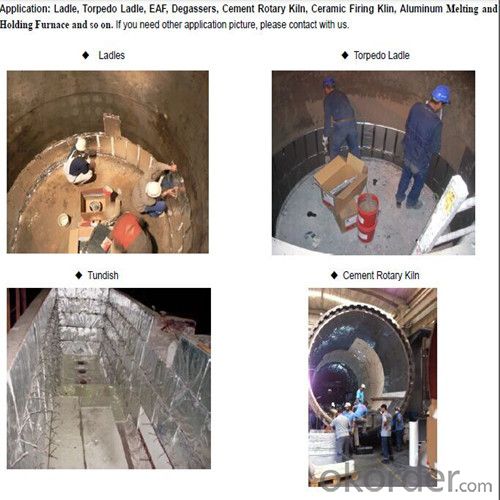

3. Applications of micropores insulation board

A. Cement industry: preheaters and cyclone separators, decomposition kiln,tertiary air duct and cooler .

B. Nonferrous metallurygical industry: aluminum power calciner and electrolysis groove.

C. Petrochemical industry: Splitting furnace,catalytic cracking furnace,petroleumpipeline,underground heat-flooding.

D.Metallurgical industry(steel plant): hot-rolling heat furnace,cool-rolling mill set,RH vacuum degassing furnace , smelters,hot deformation and heat treatment plants.

E. Power plant:preheat stove ,pipe.

F.Glass industry:melting furnace and recuperator,annealing furnace and cooling channels.

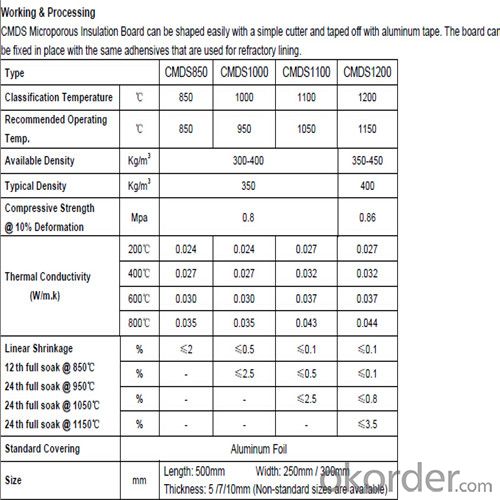

4. Technical of micropores insulation board

5.More Products To Choose

Our Services

1) High performance cost ratio with steady quality

2) OEM service and Prompt Delivery

3) The fast speed of reply your email and can make quotation sheet just for you.

4) Can provide free sample, only need you bear the sample fee.

5) Supply good after-sales service, we will follow-up the situation after using, if have problems,we will find out the

reason and deal with positively.

Other insulation products:

FAQ

Q1:Are you a manufacturer or trader?

A:Manufacturer+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q5:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q6:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q7:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q8:What is the service life of your products?

A:The service life of different Micropore/ Microporous Insulation Boards is unlike.It also depends on your using condition and method.

If you have any enquiry,please don't hesitate to contact us, we will provide our best products and services in 24 hours!!

Welcome to visit our factory!!!

- Q: I ask, our home is the top floor, the summer is too hot, the walls and roof in addition to the use of insulation board, posted their own kind of tin foil, will not be useful?

- The traditional ceiling color steel tile composite composite 10 cm thick white polystyrene foam insulation board, the insulation effect is not very good, this is because the thermal conductivity of polystyrene foam board is relatively high (thermal conductivity 0.035W / (m · K) above), plus There is a gap between the foam board and the board, the temperature is very serious, the comprehensive thermal conductivity is generally higher than 0.05. The new polyurethane spray insulation material can be directly sprayed on the color steel tile, the thermal conductivity is low, only 0.022-0.024W / (m · K), insulation effect is 2-3 times the polystyrene board, is the insulation of all insulation materials Especially excellent material. Because in the construction of the use of direct spray molding technology, so that the polyurethane foam layer is not the overall burden of sewing the body to form a complete impermeability, fundamentally put an end to the possible deep Sex. Which play a preservative effect.

- Q: Is the thermal conductivity of the vacuum insulated plate used to protect the hot plate method?

- This place is different in different places, the calculation is not the same. We are here so: independent columns need to calculate the scaffolding to (peripheral circumference +3.6) multiplied by the column height calculation, 3.6 meters below the single row of scaffolding, 3.6 meters above the corresponding height of the double row. With the overall beam of the beam does not calculate the scaffolding. You say the frame column, to distinguish between different situations.

- Q: What brand of refrigerator is using a vacuum insulation board? What kind of insulation board is better? More

- Aluminum generally refers to anodized aluminum, not magnesium alloy. Apple, Dell alien field arc spot some of the old roar M18x (note only M18x is, other models are not) XPS series, all the super class such as Acer hummingbird, Lenovo U300s

- Q: What is the best insulation material? To be waterproof.

- Under normal circumstances, the steel structure of the plant panel can be a single laminated steel plate, double laminated steel plate, composite color plate. Single-layer steel plate used for simple plant or temporary plant roof, this material is affordable, but the insulation effect is poor, easy to leak. Double laminated steel plate effect will be better. Composite color steel plate for the use of insulation materials sandwich practice, insulation and noise effects are very good, but as a roof, the national standard requires sandwich material must be flame retardant or non-combustible materials.

- Q: External wall insulation material which is good, external wall insulation materials

- Indoor insulation material that the best, fire, environmental protection, good insulation effect? ??Glass fiber. Good insulation. Glass fiber cotton with numerous fine gas holes, fibers arranged irregularly arranged, heat conduction breakdown of 0.03w / cm.k, is an excellent insulation material; . with non-flammable. Glass fiber cotton will not burn, no deformation, no embrittlement, can withstand 700 degrees of high temperature, the combustion performance to A1; . environmental non-toxic. As the glass fiber cotton in the manufacturing process does not add any adhesive, so there is no smell, high temperature will not be distributed when the toxic, pungent smell, smell, etc .; . high insulation. As the glass fiber cotton used in the raw material is glass, non-conductive, so it has a very high insulation; . corrosion resistance. Glass fiber is not afraid of strong acid, with a strong corrosion resistance, even if the use of long time will not reduce its functional characteristics; . good recovery Glass fiber contains numerous fixed cavitation, with excellent recovery, not afraid of any shock, tensile strength are more than 1.0kg; . do not want to light field scrambled decanoate containing mutual water. The moisture absorption of glass fibers is usually close to zero, do not worry about there will be water swelling caused by wet cracking of the situation. I hope my answer can help you.

Send your message to us

VIP Boards Micropores Insulation Fireproof Board for Fire Elevator

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords