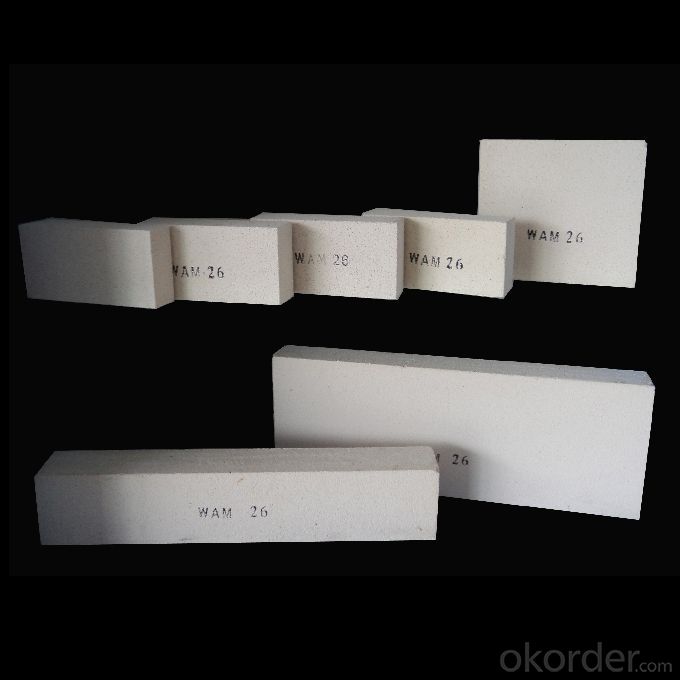

Insulating Fire Brick - Refractory Mullite Insulating Fire Brick GJM23

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

CMAX insulating firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

1. Lower content of iron, alkaline and impurities, good high temperature properties.

2. Homogeneous structure, light weight, energy saving because lower heat storage in the furnace during cooling cycles.

3. High strength, good thermal shock resistance under high temperature.

4. Precise sizes due to grinding and shaping after sintering, which meets the requirement of construction.

5. Max service temp: Up to 1730C (3160F)

Feature

Light weight and low thermal conductivity

Low heat storage

Low iron and impurities

High thermal shock resistance

Application

CMAX insulating firebricks can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass.

ITEM | GJM30 | GJM28 | GJM26 | GJM23 |

Classification Temperature, ℉/℃ | 3000/1650 | 2800/1540 | 2600/1430 | 2300/1260 |

Bulk Density,g/cm³ | ≤1.0 | ≤0.9 | ≤0.8 | ≥0.5 |

Reheating Linear Change, % | ≤0.9 (1550℃,12 h) | ≤0.8 (1510℃,12 h) | ≤0.7 (1410℃,12 h) | ≤0.5 (1230℃,12 h) |

Al2O3 Content, % | ≥75 | ≥65 | ≥55 | ≥45 |

Fe2O3 Content, % | ≤0.5 | ≤0.6 | ≤0.7 | ≤1.0 |

Thermal Conductivity: | ||||

800℃, w/m.k | ≤0.39 | ≤0.37 | ≤0.35 | ≤0.18 |

1000℃, w/m.k | ≤0.43 | ≤0.41 | ≤0.39 | ≤0.20 |

1200℃, w/m.k | ≤0.48 | ≤0.46 | ≤0.43 | --- |

- Q: Can insulating fire bricks be used in blast furnaces?

- Yes, insulating fire bricks can be used in blast furnaces. Insulating fire bricks are designed to withstand high temperatures and provide excellent thermal insulation, making them suitable for lining the walls of blast furnaces. Their insulation properties help to minimize heat loss and improve energy efficiency in the furnace, ultimately enhancing the overall performance and productivity of the blast furnace.

- Q: What is the recommended curing time for insulating fire bricks?

- The curing time for insulating fire bricks can vary based on factors like brick type, application, and manufacturer instructions. Generally, it is recommended to allow at least 24 to 48 hours for curing. This enables proper drying and hardening, ensuring stability and performance in high-temperature settings. To achieve optimal results, it is crucial to adhere to the manufacturer's guidelines and recommendations for curing time. Furthermore, factors like humidity, temperature, and ventilation can impact the curing process, so it is essential to consider them when determining the appropriate curing time for insulating fire bricks.

- Q: The insulation layer destroyed after use of cement paste and tiling

- The most certain and the method can increase the area of the balcony is to eradicate the insulation layer exposed after cement wall tiles.

- Q: Can insulating fire bricks be used in the construction of steam generators?

- Yes, insulating fire bricks can be used in the construction of steam generators. Insulating fire bricks are designed to have excellent thermal insulation properties, which make them ideal for applications where high temperatures and thermal stability are required. Steam generators operate at high temperatures and require efficient heat transfer, which means that insulation is essential to prevent heat loss and increase energy efficiency. Insulating fire bricks can withstand extreme temperatures and provide effective insulation, reducing heat losses and improving the overall efficiency of steam generators. Additionally, their lightweight nature makes them easy to handle and install in the construction process. Therefore, insulating fire bricks are a suitable choice for the construction of steam generators.

- Q: Are insulating fire bricks suitable for use in the construction of lime kilns?

- Yes, insulating fire bricks are suitable for use in the construction of lime kilns. Insulating fire bricks have high thermal insulation properties, which helps in retaining heat within the kiln. This insulation is essential for maintaining high temperatures necessary for lime production. Additionally, insulating fire bricks are lightweight and durable, making them an ideal choice for lime kiln construction.

- Q: Can insulating fire bricks be used in the construction of steam generators?

- Yes, insulating fire bricks can be used in the construction of steam generators. These bricks are designed to withstand high temperatures and provide insulation, making them suitable for applications such as steam generators where heat retention is important.

- Q: Can insulating fire bricks be used in DIY projects?

- Yes, insulating fire bricks can certainly be used in DIY projects. These bricks are lightweight and have excellent thermal insulation properties, making them suitable for various applications. They are commonly used in projects such as constructing wood-fired ovens, fire pits, kilns, and even for building the walls of a forge. Insulating fire bricks can withstand high temperatures and are resistant to thermal shock, making them a reliable choice for DIY enthusiasts who want to create heat-resistant structures. They are also easy to cut and shape, allowing for customization according to specific project needs.

- Q: Can insulating fire bricks be used in low-temperature applications as well?

- In low-temperature scenarios, insulating fire bricks can be utilized to minimize heat loss and maintain a consistent temperature. They are suitable for insulating walls, floors, and roofs of structures or equipment that require temperature regulation, such as cold storage facilities, refrigerators, or freezers. In addition, insulating fire bricks are commonly employed in low-temperature furnaces and kilns to reduce energy consumption and maintain a steady temperature during the heating process. Their exceptional insulation properties ensure that the heat generated within the furnace or kiln remains contained, reducing heat loss and enhancing overall energy efficiency. Moreover, insulating fire bricks are lightweight and easy to handle, making them convenient for various low-temperature applications. They are also resistant to thermal shock and provide outstanding structural stability, guaranteeing long-lasting performance even in demanding environments. Overall, insulating fire bricks can be effectively utilized in low-temperature applications to improve energy efficiency, temperature control, and structural stability.

- Q: Do insulating fire bricks have a high electrical resistivity?

- Insulating fire bricks are generally characterized by their high electrical resistivity. This characteristic arises from their specific design, which aims to minimize thermal conductivity and maximize thermal resistance. Consequently, the insulating materials employed in these bricks, including alumina, silica, and other refractory materials, exhibit inherently high electrical resistivity. Moreover, the manufacturing procedures frequently incorporate the incorporation of insulating additives, thereby augmenting the electrical resistivity of the fire bricks. Consequently, insulating fire bricks prove to be highly effective in mitigating heat transfer and sustaining elevated temperatures across diverse industrial applications, such as kilns, furnaces, and thermal insulation systems.

- Q: Are insulating fire bricks suitable for high-temperature kilns?

- Yes, insulating fire bricks are suitable for high-temperature kilns. Insulating fire bricks are designed to withstand high temperatures and provide excellent thermal insulation, making them ideal for use in kilns that require high operating temperatures. These bricks are made from lightweight and porous materials, such as clay or silica, which have low thermal conductivity. This allows them to effectively trap heat within the kiln and prevent heat loss, while also providing insulation against the external environment. Additionally, insulating fire bricks have good resistance to thermal shock, meaning they can withstand rapid temperature changes without cracking or breaking. Overall, insulating fire bricks are a reliable and efficient choice for high-temperature kilns.

Send your message to us

Insulating Fire Brick - Refractory Mullite Insulating Fire Brick GJM23

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords