Insulating Fire Brick 65% Al2O3 min High Alumina

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Insulating Fire Brick

Insulating Fire Brick 65% Al2O3 min High Alumina is a kind of insulation material adopting organic matter as ignition loss substance in order to increase the porosity of refractory, which has such advantages as high porosity, small volume density, good insulation effect, high mechanical intensity, small thermal conductivity and long service life. For various industrial kilns & furnaces, Insulating Fire Brick is a kind of essential refractory for energy saving and temperature preservation.

This series of High Alumina Insulating Fire Brick are made of selected high alumina bauxite, kaolin caly, hollow microsphere as the mian material. By shaping at high pressure and sintering at high temperature.

Features of Insulating Fire Brick

1. Lower content of iron, alkaline and impurities, good high temperature properties.

2. Homogeneous structure, light weight, energy saving because lower heat storage in the furnace during cooling cycles.

3. High strength, good thermal shock resistance under high temperature.

4. Precise sizes due to grinding and shaping after firing, which meets the requirement of construction.

Specifications for Insulating Fire Brick

SSW-23 | SSW-25 | SSW-26 | SSW-28 | SSW-30 | SSW-32 | ||

ASTM C155-97 °C Classification Temperature °F | 1260 2300 | 1350 2500 | 1430 2600 | 1540 2600 | 1650 3000 | 1760 3200 | |

ASTM C134-95 g/cm³ Bulk Density ib/ft³ | 0.60 37 | 0.80 50 | 0.80 50 | 0.90 56 | 1.03 64 | 1.25 78 | |

ASTM C133-97 Mpa Cold Crushing Strength ib/in² | 1.2 170 | 2.0 284 | 2.0 284 | 2.6 370 | 2.8 398 | 3.4 484 | |

ASTM C133-97 Mpa Modulus of rupture ib/in² | 0.9 128 | 1.2 170 | 1.5 218 | 1.6 232 | 1.7 247 | 2.0 290 | |

ASTM C210-95 % Permanent Liner Change °C*hrs | 0 1230*24 | -0.5 1350*24 | -0.5 1400*24 | -0.8 1510*24 | -0.9 1620*24 | -0.9 1730*24 | |

ASTM C182-88 Thermal Conductivity (W/m.k) | 400°C | 0.17 | 0.24 | 0.24 | 0.30 | 0.40 | 0.49 |

600°C | 0.19 | 0.28 | 0.27 | 0.32 | 0.42 | 0.50 | |

800°C | 0.22 | 0.32 | 0.30 | 0.35 | 0.44 | 0.51 | |

1000°C | 0.25 | 0.37 | 0.32 | 0.38 | 0.45 | 0.53 | |

1200°C | --- | --- | 0.35 | 0.39 | 0.47 | 0.55 | |

Chemical Analysis of Insulating Fire Brick | |||||||

Al2O3 % | 45 | 50 | 55 | 65 | 72 | 76 | |

Fe2O3 % | 0.9 | 0.8 | 0.8 | 0.5 | 0.4 | 0.3 | |

SiO2 % | 50 | 45 | 42 | 32 | 26 | 22 | |

CaO+MgO % | 0.7 | 0.6 | 0.3 | 0.2 | 0.3 | 0.2 | |

K2O+Na2O % | 1.3 | 1.0 | 1.0 | 0.8 | 0.2 | 0.1 | |

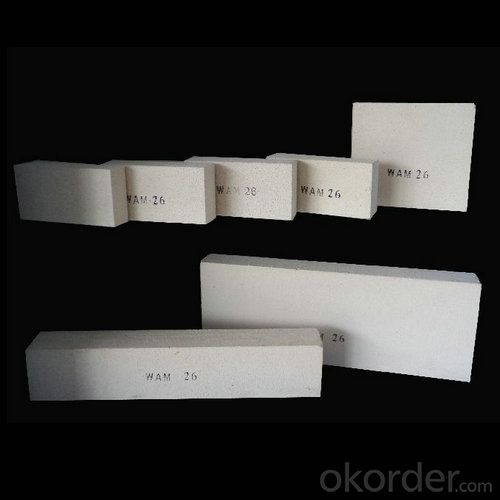

Images of Insulating Fire Brick

Applications of Insulating Fire Brick

1. Building materials for blast furnace

2. Building materials for hot-blast stove

3. Building materials for coke oven

4. Building materials for steel making furnace

5. For construction material in steel industry

6. For ladle

FAQ of Insulating Fire Brick

1. Which products do you have?

We have all kinds of refractory brick, castable, mortar, cement, ceramic fiber products, etc.

Or you could browse our products to choose what you need.

2. Can you give me a general idea of the specification and technical data of your products?

CNBM offer a range of refractory and insulation products. We provide refractory bricks, monolithic refractories as well as ceramic fiber products. And On your given shapes, drawings or description, we are producing refractories with all sizes and shapes, resistant to temperature from 800 °C till 1800 °C, using various machines and equipments for cutting, grinding, drilling, polishing, shaping processes.

Every refractory product by CNBM is of superior quality. Lesser refractory products can not approach. CNBM utilizes proprietary testing methods, testing for chemical content, density, apparent porosity, cold crush strength and modulus of rapture. With stringent quality control, you can count on CNBM products to exceed refractory industry standards and your expectations.

3. Can you give me a brief introduction of the application of your products?

We are mainly specializing in the refractory materials in iron and steel, cement, glass, ceramics, petrochemical, electric power Industry, etc.

4. If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc.

If any question, please contact us freely.

- Q: Are insulating fire bricks resistant to thermal fatigue?

- Yes, insulating fire bricks are generally resistant to thermal fatigue due to their ability to withstand repeated heating and cooling cycles without significant damage or deterioration. Their high thermal shock resistance and low thermal conductivity make them ideal for applications where thermal cycling occurs frequently.

- Q: Do insulating fire bricks require regular maintenance?

- Insulating fire bricks do not require regular maintenance as they are designed to withstand high temperatures and resist wear and tear. They are made from materials that are highly durable and have excellent insulation properties. However, it is important to periodically inspect them for any cracks, chips, or signs of damage. If any damage is found, it should be repaired promptly to ensure the bricks continue to function optimally. Additionally, regular cleaning of the bricks can help remove any build-up of debris or residue, which can affect their insulating properties. Overall, while insulating fire bricks do not require frequent maintenance, regular inspections and occasional cleaning are recommended to ensure their longevity and performance.

- Q: Are insulating fire bricks resistant to carbon monoxide attack?

- Yes, insulating fire bricks are resistant to carbon monoxide attack. These bricks are designed to withstand high temperatures and are made from materials that have low thermal conductivity. This makes them highly resistant to chemical reactions, including carbon monoxide attack.

- Q: Can insulating fire bricks be used in the construction of smelting ovens?

- Yes, insulating fire bricks can be used in the construction of smelting ovens. Insulating fire bricks are designed to have low thermal conductivity, which means they are excellent at retaining heat. This property makes them ideal for applications where high temperatures need to be maintained, such as smelting ovens. Smelting ovens are used to melt and refine various metals and minerals. These processes involve extremely high temperatures, and it is crucial to minimize heat loss to ensure efficient and effective smelting. Insulating fire bricks can help achieve this goal by providing excellent insulation and reducing heat loss. Insulating fire bricks are made from lightweight materials, such as ceramic fibers or expanded clay, which have high insulating properties. They are capable of withstanding temperatures up to 3000°F (1650°C), making them suitable for the extreme heat generated in smelting ovens. Additionally, insulating fire bricks are resistant to thermal shock, meaning they can withstand rapid temperature changes without cracking or breaking. This is essential in smelting processes, which often involve heating and cooling cycles. Furthermore, insulating fire bricks are easy to work with and can be cut or shaped to fit specific dimensions or designs. This flexibility makes them highly adaptable for constructing smelting ovens of various shapes and sizes. In summary, insulating fire bricks are an excellent choice for the construction of smelting ovens due to their low thermal conductivity, high temperature resistance, thermal shock resistance, and ease of customization. They can help maintain high temperatures, reduce heat loss, and ensure efficient smelting processes.

- Q: Are insulating fire bricks resistant to nitrogen oxides?

- Yes, insulating fire bricks are resistant to nitrogen oxides.

- Q: Are insulating fire bricks resistant to thermal conductivity?

- Yes, insulating fire bricks are designed to be resistant to thermal conductivity. These bricks are made from materials with low thermal conductivity, such as lightweight refractory fibers or insulating materials like vermiculite or perlite. The purpose of insulating fire bricks is to provide thermal insulation and prevent heat transfer, making them ideal for applications where temperature control is important, such as in kilns, furnaces, or fireplaces. By reducing thermal conductivity, insulating fire bricks help to retain heat within the desired area and minimize energy loss, making them an effective choice for insulation in high-temperature environments.

- Q: Are insulating fire bricks easy to handle and install?

- Insulating fire bricks are known for their ease of handling and installation. They possess a lightweight composition, enabling effortless transportation and portability. Furthermore, their user-friendly design, in terms of shape and size, facilitates simple manipulation and installation. The majority of insulating fire bricks are equipped with pre-drilled holes or grooves, further streamlining the installation process. Moreover, these bricks offer high versatility as they can be easily cut or shaped to accommodate specific dimensions or requirements. As a result, even individuals with limited expertise or familiarity in masonry work find insulating fire bricks to be manageable and straightforward to handle and install.

- Q: Are insulating fire bricks chemically resistant?

- Insulating fire bricks are generally chemically resistant to a wide range of substances. These bricks are typically made from high-quality refractory materials such as alumina, silica, or a combination of both. These materials have excellent resistance to chemical attack, making insulating fire bricks highly resistant to the corrosive effects of various chemicals. However, it is important to note that the chemical resistance of insulating fire bricks can vary depending on the specific composition and manufacturing process. While they are generally resistant to most chemicals, there may be certain aggressive chemicals or extreme conditions that could potentially degrade or erode the bricks over time. To ensure the optimal chemical resistance of insulating fire bricks, it is recommended to consult the manufacturer's specifications or seek expert advice for specific applications. This will help ensure that the bricks are suitable for the intended chemical environment and will perform reliably over the desired lifespan.

- Q: Is it possible to cut insulating fire bricks to fit custom shapes?

- Cutting insulating fire bricks to fit custom shapes is indeed possible. These bricks, composed of lightweight materials like ceramic fiber, can be easily cut or shaped using a range of tools. Cutting methods typically involve a saw, knife, or even a hot wire cutter. However, it is crucial to prioritize safety precautions and wear protective gear while undertaking this task. Dust and sharp edges may be produced during the cutting process. By employing suitable tools and techniques, it becomes achievable to tailor insulating fire bricks to any desired custom shape.

- Q: Can insulating fire bricks be used in paper mills?

- Yes, insulating fire bricks can be used in paper mills. Insulating fire bricks are commonly used in industrial applications, including paper mills, to provide thermal insulation and protect equipment from high temperatures. They help in maintaining optimal temperature levels and enhance energy efficiency in the paper production process.

Send your message to us

Insulating Fire Brick 65% Al2O3 min High Alumina

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords