Vertical Structure Support System for Push Pull Prop

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

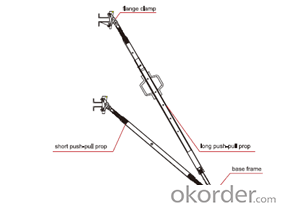

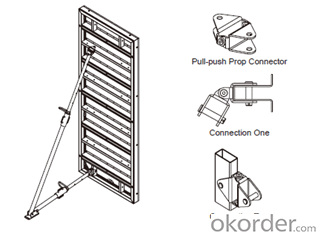

1. Structure of Push Pull Prop

Pull-push prop are used for supporting the wall and column formwork.

1.) For Timber Beam Formwork

2.) For Steel Frame Formwork

2. Main Features of Push Pull Prop

◆ High degree of standardization

◆ Simple site operations

◆ Quick adjustment

3. Push Pull Prop Images

4. Single Side Bracket Specifications

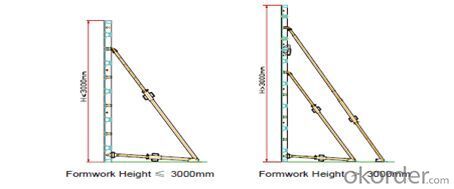

There are three kinds of pull-push props, A,B,C. The A and B is suitable for the formwork not higher than 3000mm; C is suitable for the formwork higher than 3000mm as a reinforcer.

5. FAQ of Single Side Bracket

1) What can we do for you?

.We can ensure the quality of the push pull prop and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issues.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.

- Q: Can steel props be used for temporary support in offshore platforms?

- Yes, steel props can be used for temporary support in offshore platforms. Steel props are commonly used in construction for supporting temporary structures or providing additional support to existing structures. In the case of offshore platforms, steel props can be used to provide temporary support during construction, maintenance, or repair activities. Offshore platforms are subjected to various loads and forces, including waves, wind, and the weight of equipment and personnel. During construction or maintenance work, additional loads may be applied, which can require temporary support to ensure the stability and safety of the platform. Steel props are typically made of high-strength steel and can be easily adjusted to the required height and load-bearing capacity. They provide a stable and reliable means of supporting structures temporarily, allowing for the completion of necessary work. However, it is important to ensure that the steel props used for temporary support in offshore platforms are designed and manufactured to meet the specific requirements and safety standards of the offshore industry. This includes considering factors such as corrosion resistance, load capacity, and compliance with relevant regulations and guidelines. In summary, steel props can be used for temporary support in offshore platforms, but it is crucial to choose appropriate props that are designed and manufactured to meet the specific needs of the offshore environment to ensure the safety and stability of the platform.

- Q: What are the differences and similarities between the support of wood, steel, and steel?

- Generally, the steel support is inclined connection member, the most common is the herringbone shape and cross shape, the cross section can be steel pipe, H steel, angle steel, the role is to enhance the stability of the structure. When it comes to brace generally refers to Rachel steel purlin, is thick bar, but also to enhance the stability of the purlin purlin, not easy to lose in the external force under certain failure. Section purlin are generally H steel, C shape, Z shape, is reducing cabin panel span and fixed roof panel. Steel support is a kind of steel structure, which is used as a supporting component, which is used to support the structure of large load.

- Q: How do you calculate the required number of steel props for a specific job?

- To calculate the required number of steel props for a specific job, you need to consider the load-bearing capacity of the props, the weight of the structure being supported, and the spacing between the props. By determining the maximum load capacity of each prop and dividing the total weight of the structure by the load capacity of a single prop, you can estimate the number of props needed. Additionally, considering the spacing requirements, you can calculate the overall number of props required for the job.

- Q: How do you ensure proper load distribution when using multiple steel props?

- Proper load distribution when using multiple steel props can be ensured by following a few essential steps. Firstly, it is important to determine the total load that needs to be supported and distribute it evenly among the props based on their load-bearing capacities. Secondly, the props should be positioned at regular intervals along the load-bearing structure to provide adequate support and prevent any excessive load on a single prop. Additionally, the props should be properly aligned and adjusted to ensure they are all carrying their fair share of the load. Regular monitoring and adjustment of the props during the construction process also help in maintaining proper load distribution.

- Q: I would like to ask how the cost of steel support how the composition of the material composition of the number of what the size of the various specifications of how much raw materials are required

- The cost of steelmaking process is mainly composed of pig iron, scrap steel, alloy, electrode, refractory material, auxiliary material, electricity, inspection and other expenses. At present, the main China steelmaking equipment for smelting converter and electric furnace, based on the different principle, converter and electric furnace in the main raw materials (iron and steel) ratio of certain differences, scrap converter process usually takes 10% of the usage and configuration, the electric furnace process scrap accounted for 80%.

- Q: Can steel props be used for supporting temporary residential structures?

- Steel props are capable of supporting temporary residential structures. These props, also referred to as adjustable steel props or steel acrow props, are widely employed in construction projects to offer temporary support to structures. They are designed to withstand heavy loads and provide stability during construction or renovation activities. When it comes to temporary residential structures like mobile homes, portable cabins, or temporary shelters, steel props can serve as an effective solution. They can be easily adjusted to the desired height and deliver the necessary support for the structure. Steel props possess strength, durability, and a high load-bearing capacity, making them suitable for a range of temporary residential structures. Nevertheless, it is crucial to ensure the proper installation and adherence to the specific requirements of the structure when using steel props. Seeking professional advice and expertise is essential to ascertain the appropriate size, number, and placement of steel props, guaranteeing the safety and stability of the temporary residential structure. Moreover, routine inspections and maintenance must be conducted to ensure that the steel props remain in good condition and continue to provide the necessary support. Overall, steel props can be deemed a dependable choice for supporting temporary residential structures; however, meticulous planning, installation, and maintenance are pivotal to ensure their effectiveness and safety.

- Q: What are the typical costs associated with renting steel props?

- The typical costs associated with renting steel props vary depending on various factors such as the duration of the rental, the quantity of props needed, and the location. However, on average, the cost of renting steel props can range from $2 to $6 per week for each prop. Additionally, there may be additional charges for delivery and pickup, as well as any damages that occur during the rental period. Some rental companies may require a security deposit or insurance coverage to protect against potential damages or loss of the props. It is important to note that the cost of steel props rental may also vary depending on the market demand and the specific supplier. Therefore, it is recommended to reach out to different rental companies to get accurate and up-to-date pricing information based on your specific project requirements.

- Q: Can steel props be used in hospital construction?

- Yes, steel props can be used in hospital construction. Steel props, also known as adjustable steel props or steel shoring props, are commonly used in construction projects to provide temporary support to structures. They are versatile and can be adjusted to different heights, making them suitable for various applications, including hospital construction. In hospital construction, steel props can be used for various purposes. They can provide support to ceilings, walls, and beams during the construction process. Steel props can also be used to support temporary structures such as scaffolding or formwork, which are essential for construction activities. Additionally, steel props are known for their strength and stability, which makes them a reliable choice for hospital construction. Hospitals require structures that can withstand heavy loads and provide a safe environment for patients and staff. Steel props, being made from high-quality steel, offer the necessary strength and stability required in such critical infrastructure projects. Moreover, steel props are adjustable, allowing for easy installation and adaptation to changing construction needs. Hospital construction often involves complex designs and layouts, and steel props can be easily adjusted to different heights and angles to accommodate these requirements. Furthermore, steel props are durable and long-lasting, making them a cost-effective solution for hospital construction. Hospitals are long-term investments, and using steel props ensures the longevity and stability of the structures, reducing the need for frequent repairs or replacements. Overall, steel props can indeed be used in hospital construction. Their strength, stability, adjustability, and durability make them an ideal choice for supporting various structures during the construction process.

- Q: Can steel props be used for supporting temporary aerial platforms or lifts?

- Supporting temporary aerial platforms or lifts can be achieved using steel props. These props, also referred to as adjustable steel props or scaffolding props, are commonly utilized in construction projects to offer temporary support for structures or platforms. Their adjustable height feature makes them suitable for various applications, including supporting aerial platforms or lifts. Steel props are renowned for their strength and stability, making them a dependable choice for establishing a secure and sturdy foundation for temporary platforms or lifts. Moreover, their height can be easily modified, providing flexibility in determining the desired elevation for the platforms or lifts. However, it is imperative to ensure the proper installation of steel props and adherence to required safety standards to guarantee the safety of workers and the stability of the supported structure.

- Q: Are steel props suitable for supporting temporary stages or platforms?

- Yes, steel props are generally suitable for supporting temporary stages or platforms. Steel props are strong, durable, and adjustable, making them capable of providing stable and reliable support for various types of temporary structures. Additionally, their load-bearing capacity and versatility make them a popular choice in the construction industry for temporary stage and platform installations.

Send your message to us

Vertical Structure Support System for Push Pull Prop

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords