Tripod & Beam clamp

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Prop & Tripod & Beam Clamp

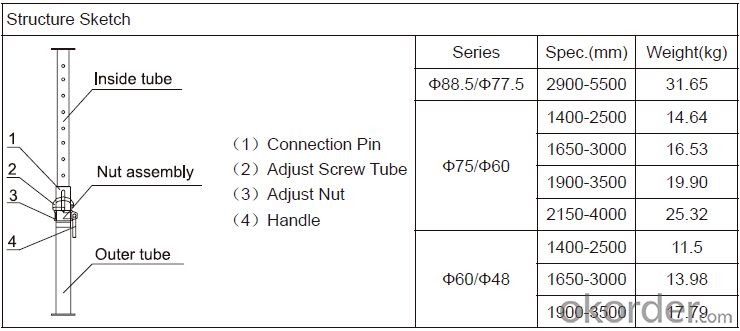

(1) Steel prop is a vertical support system widely used in construction.

Characteristics:

◆ Simple & flexible structure

◆ Easy & fast operation

◆ Economical efficiency

◆ Easy storage and transportation

◆ Reasonable load-bearing capacity

(2) Tripod is always used as support for steel prop.

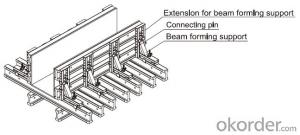

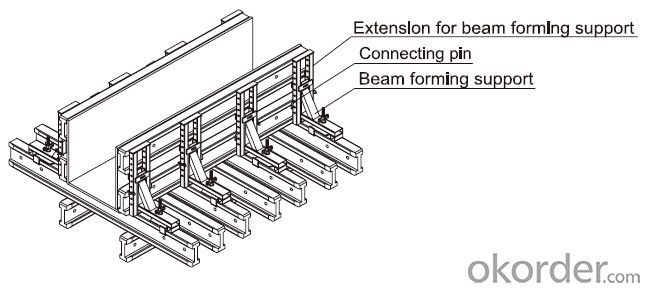

(3) The beam clamp is a technical instrument for supporting beam formwork

which makes conventional beam formwork simple, and increases the construction

efficiency.

Characteristics:

◆ Flexible structure

◆ Optimum design proposal

- Q: Can steel props be used in high-rise buildings?

- Yes, steel props can be used in high-rise buildings. Steel props, also known as scaffolding or shoring systems, are commonly used in construction to support and stabilize structures during the building process. Due to their strength and load-bearing capacity, steel props are suitable for use in high-rise buildings where additional support is needed to ensure the safety and stability of the structure.

- Q: Can steel props be used for supporting concrete slabs?

- Certainly! Steel props have the capability to support concrete slabs. Referred to as adjustable steel props or steel prop jacks, these props are frequently utilized in construction to offer temporary support and stability to structures. They possess the ability to withstand substantial loads and can be modified to achieve the desired height, thus making them an ideal choice for supporting concrete slabs in construction or renovation endeavors. In order to prevent sagging or collapse of concrete slabs prior to reaching their full strength, steel props are frequently employed. By providing dependable and robust support, they ensure that the concrete slab remains securely in place and maintains a level position throughout the curing process.

- Q: Can steel props be used in conjunction with other support systems, such as scaffolding?

- Steel props, also referred to as adjustable steel props or adjustable steel shores, are utilized in construction and renovation ventures to temporarily support substantial loads or structures. They are commonly employed for horizontal beams, slabs, formwork, and other vertical loads. On the contrary, scaffolding is a provisional structure employed to facilitate access and support for workers and materials during construction, maintenance, or repair activities. It comprises of platforms, support beams, and other components. In numerous construction projects, steel props are employed alongside scaffolding to offer supplementary support and stability. For instance, if a scaffold is erected to provide access to a higher level, steel props can be employed to uphold the scaffold's weight and ensure its stability. Likewise, steel props can be employed to sustain scaffold platforms or to reinforce vulnerable areas where added support is necessary. The amalgamation of steel props and scaffolding can heighten safety and stability on construction sites, particularly when managing heavy loads or working on elevated platforms. However, it is crucial to guarantee that both the design and installation of the steel props and scaffolding adhere to relevant safety regulations and guidelines. Meticulous planning, engineering calculations, and professional supervision are imperative to ensure the secure and efficient utilization of steel props alongside other support systems like scaffolding.

- Q: Are steel props adjustable in both tension and torsion?

- No, steel props are typically adjustable in tension only, not torsion.

- Q: Are steel props adjustable in both rotation and translation?

- Yes, steel props are adjustable in both rotation and translation.

- Q: How much should be the concrete strength of the main structure of the steel support to carry out the construction

- Support system of the special support for the following points: (1) the support of the switch must be in accordance with the principle of first support after the demolition

- Q: Are steel props adjustable in small increments or only in larger steps?

- Steel props, also known as steel shore or adjustable steel props, are designed to provide temporary support to structures during construction or renovation. These props are known for their versatility and adjustability, allowing for precise support to be provided in accordance with the specific requirements of the project. In terms of adjustability, steel props typically offer the flexibility to be adjusted in small increments, allowing for fine-tuning and precise positioning. This adjustability is crucial in ensuring that the temporary support is precisely aligned and can effectively bear the load it is intended to carry. The adjustment mechanism of steel props usually involves a threaded screw or pin system that allows for easy extension or retraction. By rotating the screw or releasing the pin, the length of the prop can be increased or decreased in small increments. This enables the construction workers to make minor adjustments to the height or alignment of the props as needed. The ability to adjust steel props in small increments is particularly advantageous when working on projects where precise measurements are required, such as leveling floors or supporting beams. It allows for greater control and accuracy, ensuring that the temporary support is optimally positioned and capable of effectively distributing the load. Overall, steel props are highly adjustable and can be fine-tuned in small increments to meet specific construction needs. Whether it is adjusting the height or alignment, these props provide the necessary flexibility to ensure a secure and stable temporary support system.

- Q: Can steel props be used for supporting temporary fences or barriers?

- Temporary fences or barriers can indeed be supported by steel props. While steel props are commonly used for supporting structures during construction or renovation projects, they can also provide stability and support to temporary fences and barriers. Due to their sturdiness and durability, steel props are an ideal choice for ensuring the stability and security of temporary fencing systems. They are easily adjustable to the desired height and can withstand external forces such as wind or accidental impact. Moreover, the installation and removal of steel props are quick, making them a convenient solution for temporary fencing needs. In summary, the use of steel props for supporting temporary fences or barriers is a dependable and efficient method to guarantee the safety and stability of the fencing system.

- Q: What are the components of a steel prop?

- The components of a steel prop typically include a steel tube or pipe, an adjustable threaded collar, a base plate or foot, and a swivel head or top plate.

- Q: What are the characteristics of steel frame bracing system

- What are the characteristics of steel frame bracing system,

Send your message to us

Tripod & Beam clamp

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords