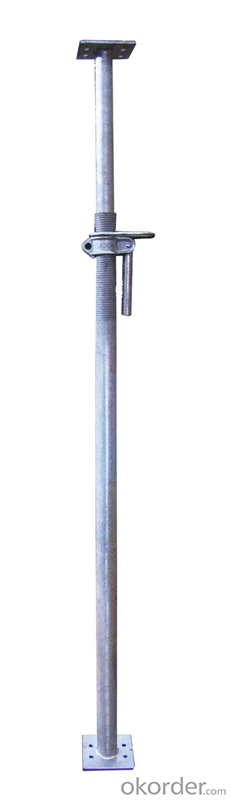

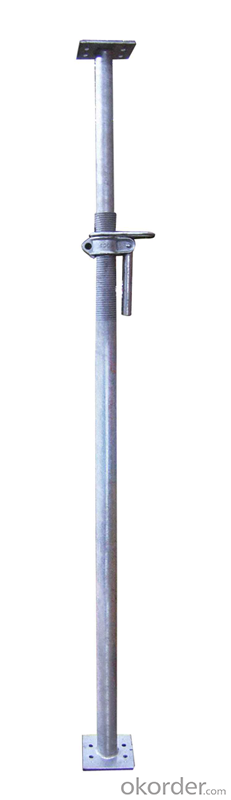

Formwork Steel Props Scaffolding for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product information:

Model Number: GTJ-P003

Name: Q235 High Quality Steel Slab Props

Material: Q235

Thickness: 1.6mm to3mm or as your requirements

Surface Treatment: as per requirements

Standard: use your standard or international standard

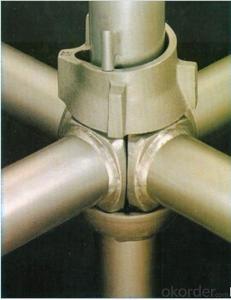

Dimension: Light duty 40-48mm, MID Duty 48-56/58mm, Heavy duty 48-60mm

Characteristics:

1. Reliable performance

2. Corrosion resistance

3. Durable finish standards

Functions

It is used for construction supporting, timber, formwork, concrete slab and so on. It is very easy and reliable to use

Why Choose Us

1. We are experienced manufacturer in Hebei with more than 4 years experience and cooperating with more many countries.

2. We supply qualified products which are certified by SGS and ISO9001:2008. Strict QC to make sure your profit.

3. Timely delivery can be guaranteed because we have a factory which covers an area of 30000sqm and its daily output is more than 50 tons.

4. A competitive price can be offered because we are a professional manufacturer of scaffolding with an advantage on cost-controlling & production management.

- Q: Are steel props suitable for supporting temporary scaffolding structures?

- Temporary scaffolding structures can be effectively supported using steel props. These props, also referred to as adjustable props or acrow props, are extensively utilized in the construction industry. They offer robust support and stability to a range of structural elements, including temporary scaffolding structures. Constructed from top-notch steel materials, these props are designed to provide reliable and durable support. Their adjustable feature allows for easy customization of height, making them adaptable to various scaffolding configurations. Not only are steel props renowned for their strength and durability, but they also prioritize worker safety and the stability of the temporary scaffolding structure. Moreover, their simple installation and dismantling process contribute to efficient construction procedures. In conclusion, steel props are a dependable and appropriate choice for supporting temporary scaffolding structures.

- Q: Can steel props be used in supporting temporary stages and platforms?

- Indeed, temporary stages and platforms can benefit from the utilization of steel props. These props, alternatively referred to as adjustable steel columns or acrow props, serve as versatile and sturdy support systems frequently employed in construction and temporary structures. Their purpose is to furnish temporary support for both horizontal and vertical loads. With the ability to adjust their height, steel props can be effortlessly tailored to the necessary elevation for supporting stages and platforms. Furthermore, their resilient steel composition guarantees stability and safety, enabling them to bear substantial loads and establish a reliable base for temporary structures.

- Q: What are the potential aesthetic considerations when using steel props?

- When using steel props, potential aesthetic considerations include the visual appearance of the props themselves, their compatibility with the surrounding environment or design, and the overall impact they may have on the aesthetic appeal of the space. Additionally, the choice of finishes, colors, or textures of the steel props can also play a role in their overall aesthetic integration.

- Q: Are steel props suitable for supporting heavy machinery?

- Yes, steel props are suitable for supporting heavy machinery. Steel props, also known as steel acrow props or steel adjustable props, are designed to provide temporary support for various construction applications, including supporting heavy machinery. Steel props are made of high-quality steel, which gives them excellent strength and load-bearing capacity. They are specifically engineered to withstand heavy loads and provide stability and support in construction sites or industrial settings. These props typically consist of an adjustable inner tube that can be extended or compressed to the desired length, along with an outer tube that provides additional strength and stability. They are designed to be easily adjustable to accommodate different heights and loads, making them versatile and suitable for various heavy machinery applications. Moreover, steel props often come with additional features such as threaded handles or pins for secure tightening and locking of the prop's length. This ensures that the prop remains firmly in place and can withstand the weight and vibrations generated by heavy machinery. Overall, steel props are a reliable and effective solution for supporting heavy machinery. However, it is essential to follow proper guidelines and ensure that the props are correctly installed and adjusted to ensure maximum safety and stability.

- Q: How do you ensure proper load distribution when using multiple steel props?

- Proper load distribution when using multiple steel props can be ensured by following a few essential steps. Firstly, it is important to determine the total load that needs to be supported and distribute it evenly among the props based on their load-bearing capacities. Secondly, the props should be positioned at regular intervals along the load-bearing structure to provide adequate support and prevent any excessive load on a single prop. Additionally, the props should be properly aligned and adjusted to ensure they are all carrying their fair share of the load. Regular monitoring and adjustment of the props during the construction process also help in maintaining proper load distribution.

- Q: How do you ensure proper stability when using steel props on soft ground?

- To ensure proper stability when using steel props on soft ground, there are a few important measures that can be taken: 1) Ground Assessment: Before using steel props, it is crucial to assess the ground conditions. Soft ground can include soil with low bearing capacity or areas prone to sinking. Conducting a thorough ground assessment will help determine the appropriate measures to be taken. 2) Load Distribution: Distributing the load over a larger area can help minimize the pressure exerted on the soft ground. This can be achieved by using larger base plates or timber mats to spread the load evenly. 3) Depth and Size of Props: Consider using longer and larger diameter steel props when working on soft ground. Longer props will provide better stability by reaching deeper, more stable soil layers. Similarly, larger diameter props will distribute the load more evenly and reduce the risk of sinking. 4) Reinforcement: In some cases, additional reinforcement may be required to enhance stability. This can be achieved by using steel plates or beams to provide additional support to the props. Reinforcement will help distribute the load more effectively and minimize the risk of sinking. 5) Regular Monitoring: It is important to continuously monitor the stability of the steel props and the ground conditions throughout the project. Regular inspections will help identify any potential issues or instability and allow for timely corrective measures to be taken. By following these measures, proper stability can be ensured when using steel props on soft ground, minimizing the risk of accidents and ensuring the safety of workers and the surrounding environment.

- Q: Basement slab reinforcement drawings did not explain how to calculate the final accounts?

- Is only part of the sample was not standard, still construction

- Q: How do you calculate the required spacing between steel props?

- To ensure the safe and efficient support of a structure, several factors must be considered when calculating the required spacing between steel props. The following are the key steps involved in this calculation: 1. Start by determining the load that the steel props need to support, which includes the weight of the structure, any additional live loads, and any concentrated loads that may be present. 2. Next, assess the load-bearing capacity of the steel props being used. This information can typically be obtained from the manufacturer's specifications or load tables. It is important to consider both the maximum axial load and the maximum moment capacity of the props. 3. Divide the total load by the number of props to determine the load that each individual prop needs to support. Ensure that the individual prop load does not exceed the load-bearing capacity of the props. 4. Determine any spacing limitations based on the specific requirements of the project or the manufacturer's guidelines. These may include maximum and minimum spacing requirements, influenced by factors such as the prop's length, stability, or bracing requirements. 5. Take into account the deflection of the steel props under load. Typically, a maximum allowable deflection limit is provided by the manufacturer. Ensure that the spacing is such that the deflection of each prop remains within this limit. 6. Divide the maximum allowable deflection by the deflection of each prop under load to determine the number of props needed to achieve the desired spacing. It is important to ensure that the resulting number of props is practical and feasible within the given project constraints. 7. Finally, consider any additional factors that may impact the spacing calculation, such as wind loads, seismic loads, or any other relevant design considerations. Adjustments to the spacing calculation may be necessary to ensure the stability and safety of the structure. During the calculation process, it is crucial to consult with a structural engineer or a qualified professional to ensure accuracy and adherence to safety standards and local building codes.

- Q: Can steel props be used in the construction of hotels?

- Steel props, also known as steel shoring or steel support systems, are widely employed in the construction industry, including hotel construction. These props serve as temporary supports during the construction process, providing stability and safety to structures. They are easily adjustable and can be conveniently installed and removed, making them an ideal choice for construction projects necessitating temporary support. In hotel construction, steel props play a crucial role in supporting the weight of concrete slabs, walls, and other building components. Additionally, their adaptability in terms of height adjustment makes them suitable for a variety of construction scenarios and requirements. In summary, steel props are a dependable and extensively utilized tool in the construction industry, including the construction of hotels.

- Q: Can steel props be used for supporting temporary structures during disaster relief efforts?

- Indeed, steel props have the capability to support temporary structures during the course of disaster relief endeavors. These props are extensively employed in construction and have been specifically engineered to furnish provisional reinforcement to structures. They possess the ability to adjust their height and are capable of sustaining substantial loads, rendering them ideal for a multitude of purposes, including disaster relief initiatives. Steel props can be effectively utilized to stabilize structures that have incurred damage or have collapsed, bestow supplementary support to structures that have been weakened, or even establish temporary shelters for individuals affected by the calamity. Due to their robustness and endurance, steel props prove to be dependable and proficient in providing support to temporary structures during the course of disaster relief efforts.

Send your message to us

Formwork Steel Props Scaffolding for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords