Adjustable Prop Vertical Robust Suspended Slab Formwork System

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

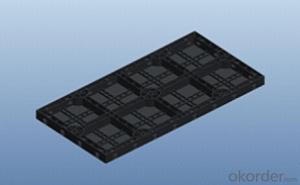

suspended slab formwork

slab form work

concrete slab formwork

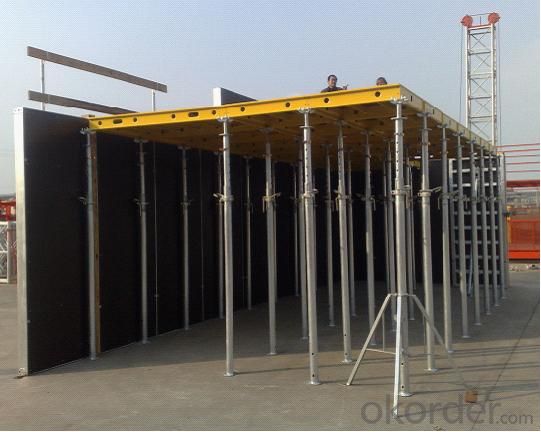

Adjustable Prop Vertical Robust Suspended Slab Formwork System

Description:

1. Brief introduction

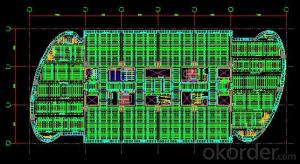

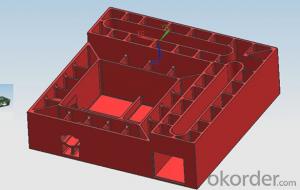

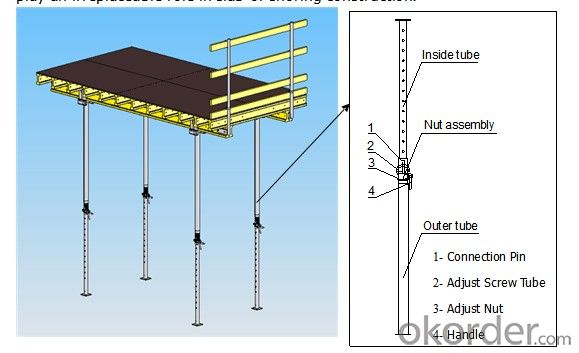

A vertical support system widely used in construction of slab or shoring. The prop has simple structure; it is easy to operation and has perfect adjustment to each individual job site requirement, all these features decide that the props play an irreplaceable role in slab or shoring construction.

2. Competitive advantage

① Simple structure, easy operation.

As the above picture shown, the prop has very simple structure. The height of prop is adjustable by means of the relative position of inside tube and outer tube. And the light adjustment will be achieved by rotating adjust nut. It is very easy to operate for every labor.

②Reasonable load-bearing capacity.

The prop is mainly used for supporting slab formwork, especially for table formwork, its load-bearing capacity is undoubted important to be construction safety. The props have two series according to different load-bearing capacity: 30KN per set and 20KN per set with maximum height. Usually, we take 2 times safety factors in formwork design.

3. Applications

- Q: Who used it, how not universal.

- 4. The product pouring concrete surface smooth, bright as a mirror, to meet the requirements of decorative and decorative water, eliminating the need for secondary plastering process. 5. Turnover times more than 50 times, the template each time the amortization cost is less than 3 yuan, steel frame plastic template turnover times more than 300 6. The material is non-toxic, harmless, pollution-free, 100% recovery, green products The 7. The product acid, alkali, anti-corrosion performance. Product use temperature of -80 ℃ ~ 100 ℃, good weather resistance.

- Q: I heard that there are building aluminum template and plastic template it? Which is better?

- Wood-plastic building templates in the construction works more useful, more affordable, more convenient.

- Q: Europe and the United States national construction template is made of plastic or wood

- With plastic construction, then, is the most solid touch on the back, Europe and the United States part of the country after the earthquake so the use of wood plus wire

- Q: We have to start the construction site immediately, and have not used this plastic building template; I would like to ask you all the big brother who used this plastic building template ah? How is the quality of ah? So good ah?

- The production of plastic building template not only has the many advantages of plastic template, but also successfully broke the plastic building template price is high, the price is equivalent to the current construction industry commonly used bamboo sheet, while giving the plastic template more advantage.

- Q: Want to purchase a number of building templates and found a new plastic building template, do not know how the quality?

- Plastic construction template is the disadvantage of airtight and non-absorbent, in the mold, the wall will blister, can not meet the construction requirements, especially high-rise buildings, repeated use after a few times can no longer use. At present, a large number of domestic or wood template.

- Q: Types of building templates? What is the water template?

- The type of template, according to the material to wood template, steel formwork, bamboo template, Gangmu combination template, etc.

- Q: How does the concrete on the plastic template remove (already glued to the concrete)

- With pliers slowly pull, or spray gun spray.

- Q: I heard that plastic construction template workers do not want to use, there is such a situation

- Are generally wood board, plastic with less

- Q: The price of raw materials can say better, is the PVC material.

- General templates are fixed specifications, such as 1.22 * 2.44,980 * 2200 so it is generally in accordance with each template to price

- Q: Shear wall plastic template for the wall height and thick ratio requirements is how much?

- The support system of the building template should be able to maintain the safety and reliability of the vertical placement of the building template and its own stability under the wind load. The length of the foot adjustment bolt should meet the need to adjust the vertical installation of the template and adjust the self-stabilizing angle. The foot adjustment device should be easy to adjust and turn flexible. Panel should be used not less than 5mm thickness of the production of steel, the material should not be lower than the performance requirements of Q215A, the template of the ribs and back corure should use steel, cold-formed thin-walled steel production, material and steel panel material should be the same brand to ensure Welding performance and structural properties. Panel system, support system, operating platform system and connectors and other components. Composition of the building template The connection between the various systems must be safe and reliable.

Send your message to us

Adjustable Prop Vertical Robust Suspended Slab Formwork System

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords