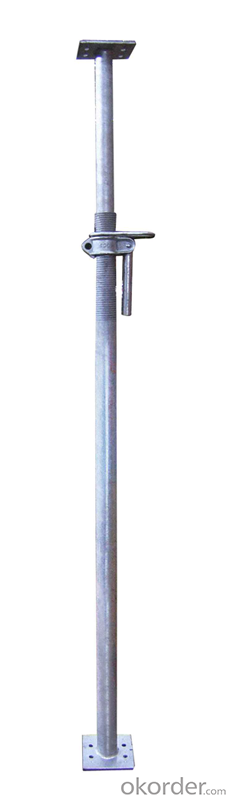

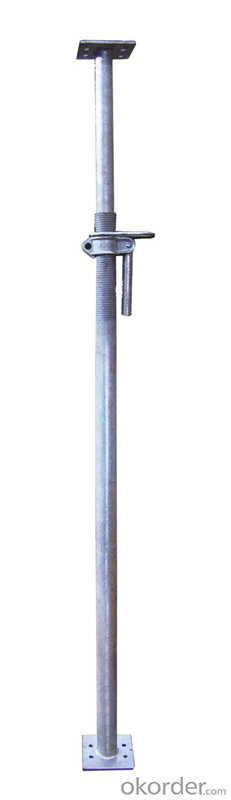

Construction Support Steel Props of Scaffolding System

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Steel Props:

1. Steel Prop consists of internal pipe, external pipe, prop sleeve, nut, pin, top and bottom plate.

2. Steel Prop is widely used as support system in beam, slab, formwork, concrete and floor support.

3. Steel Prop can be surface treatment red oil painting or powder coated or galvanized to further resist rust, cracking and corrosion, has no pollution or harm to the environment and human body, which make sure of its low damage and longer life span.

4. Steel Prop has fewer components, easy and quick assembly.

5. Steel Props has high bearing capacity, as steel pipe material is Q235, thickness can be 1.8mm to 3.0mm, diameter 40-48mm,48-56mm,48-60mm. According to SGS test report, one prop with 2.2mm of thickness, 48-60mm diameter can load 1.8tons, which is heavy duty Steel Props .

6.We can meet all kinds of steel props , Italian tye, Spanish type for South Amercia, Middle East type. aole the requiremnets, such as U head, fork head, rosette head, plate, etc.

Technical parameters

Model Number: adjustable steel prop

Material: Q235 steel tube raw material

Surface Treatment: Galvanized,Dip Painted,Powder coated

Color: silver,dark red,yellow,blue,green and more colore

Application: building construction shoring props for inside concrete wall support

tube thickness: 1.8/2.0/2.2/2.5/3.0mm

adjustable length: 1600-2900/1800-3200/2000-3600/2200-4000mm as your request

base plate size: 120*120*5mm or as your request

Working life: 4-6 years normally

inner tube diameter: 40mm,or 48mm

outer tube diameter: 48mm,or 56/58/60mm

Packaging & Delivery

In bulk or steel pallet. props will be bundle with wooden pallet or bare package in container one 20ft container can load steel props 1800pcs to 2500pcs.

20 to 30 days to main port of China after order confirmation

- Q: Are steel props adjustable for supporting structures with irregular shapes?

- Yes, steel props are adjustable and can be used to support structures with irregular shapes. The adjustable nature of steel props allows for customization and flexibility, making them suitable for various shapes and sizes of structures.

- Q: Can steel props be used for temporary support in airport construction?

- Yes, steel props can be used for temporary support in airport construction. Steel props are commonly used in construction projects to provide temporary support to structures. They are adjustable and can be easily installed, making them suitable for various construction needs, including airport projects.

- Q: Can steel props be used in wastewater treatment plant construction?

- Yes, steel props can be used in wastewater treatment plant construction. Steel props are commonly used in construction projects to support temporary structures, such as formwork, scaffolding, and shoring systems. In the case of a wastewater treatment plant, steel props can be used to provide temporary support to various components during construction, including tanks, pipelines, and equipment. Steel props offer strength, stability, and adjustability, making them suitable for use in the dynamic and demanding environment of a wastewater treatment plant construction site.

- Q: Steel support is now about how much the price

- Steel support prices will follow the market price of steel, and now probably about 3800 yuan / ton, of course, one day a price.

- Q: Can steel props be used for temporary support in mining operations?

- Certainly, steel props have the capability to be utilized for temporary support within mining operations. In the realm of underground mining, steel props are frequently employed to offer temporary reinforcement to the roof, walls, and tunnels. Their purpose is to endure the immense weight and pressure imposed by the surrounding rocks, thereby averting any potential collapse or displacement of the mine structure. With their adjustable nature, steel props enable miners to effortlessly establish the desired height and maintain an unbroken support system as mining operations proceed. Furthermore, they possess exceptional durability and an exceptionally high resistance to corrosion, rendering them suitable for deployment in the demanding conditions found within mining environments. All in all, steel props represent a dependable and efficient remedy for temporary support requirements within mining operations.

- Q: How do steel props compare to wooden props in terms of strength?

- Steel props are generally much stronger than wooden props in terms of strength. Steel is a highly durable and robust material, capable of bearing heavy loads and providing excellent structural support. It has a high tensile strength, which means it can resist bending or breaking under pressure. On the other hand, wooden props, while still capable of supporting certain loads, are more prone to warping, splitting, or deteriorating over time. They are not as resistant to weight and external forces as steel props. Therefore, in terms of strength and durability, steel props are a more reliable choice for construction or structural support applications.

- Q: 7.5 square meters of toughened glass floor C steel support costs about how much

- 1.4 m high concrete beam, along the beam to the vertical bar spacing is not greater than 500mm.

- Q: What are the different weight capacities of steel props?

- The weight capacities of steel props can vary depending on their size and specifications. Steel props, also known as adjustable steel props or acrow props, are commonly used in construction and temporary support applications to provide vertical support and stability to structures or formwork systems. The weight capacity of steel props typically depends on their load-bearing capabilities, which are determined by factors such as the prop's height, diameter, and material strength. In general, steel props are designed to support heavy loads and can have weight capacities ranging from a few hundred kilograms to several tons. Smaller steel props, such as those with a height of around 1-2 meters and a diameter of 40-50mm, usually have weight capacities of up to 2-3 tons. These props are commonly used for lighter support applications, such as supporting beams or formwork for slabs and walls. Medium-sized steel props, with heights ranging from 2-4 meters and diameters around 50-60mm, can typically handle weight capacities of around 3-5 tons. These props are often used for supporting heavier loads, such as larger beams or formwork systems for multi-story structures. Larger steel props, which can have heights exceeding 4 meters and diameters of 60mm or more, are capable of supporting even heavier loads. These props can have weight capacities of 5-10 tons or more, depending on their specific design and material strength. They are commonly used for supporting heavy beams, columns, or other structural elements during construction or renovation projects. It's important to note that the weight capacity of steel props may also be influenced by other factors, such as the condition of the ground or the type of load being supported. Therefore, it is crucial to consult the manufacturer's specifications or seek professional advice to ensure the proper selection and use of steel props for a specific application.

- Q: Can steel props be used in residential renovations?

- Yes, steel props can be used in residential renovations. Steel props are commonly used in construction projects, including residential renovations, to provide temporary support to walls, ceilings, or other structures during the renovation process. These props are adjustable and can be easily installed, making them a practical and reliable choice for residential renovations.

- Q: Steel support can stay in the wall joint position, if not, then why?

- 1, to 2, in order: first the site even wall, etc. the wall concrete reached a certain strength, in the wall at the seams on the outside the foundation construction of high pressure jet grouting pile

Send your message to us

Construction Support Steel Props of Scaffolding System

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords