Construction Heavy Duty Support Steel Props

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Steel Props:

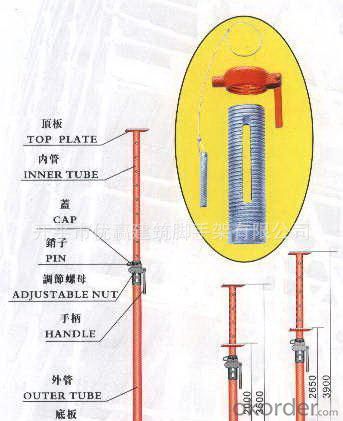

1. Steel Prop consists of internal pipe, external pipe, prop sleeve, nut, pin, top and bottom plate.

2. Steel Prop is widely used as support system in beam, slab, formwork, concrete and floor support.

3. Steel Prop can be surface treatment red oil painting or powder coated or galvanized to further resist rust, cracking and corrosion, has no pollution or harm to the environment and human body, which make sure of its low damage and longer life span.

4. Steel Prop has fewer components, easy and quick assembly.

5. Steel Props has high bearing capacity, as steel pipe material is Q235, thickness can be 1.8mm to 3.0mm, diameter 40-48mm,48-56mm,48-60mm. According to SGS test report, one prop with 2.2mm of thickness, 48-60mm diameter can load 1.8tons, which is heavy duty Steel Props .

6.We can meet all kinds of steel props , Italian tye, Spanish type for South Amercia, Middle East type. aole the requiremnets, such as U head, fork head, rosette head, plate, etc.

Technical parameters

Model Number: adjustable steel prop

Material: Q235 steel tube raw material

Surface Treatment: Galvanized,Dip Painted,Powder coated

Color: silver,dark red,yellow,blue,green and more colore

Application: building construction shoring props for inside concrete wall support

tube thickness: 1.8/2.0/2.2/2.5/3.0mm

adjustable length: 1600-2900/1800-3200/2000-3600/2200-4000mm as your request

base plate size: 120*120*5mm or as your request

Working life: 4-6 years normally

inner tube diameter: 40mm,or 48mm

outer tube diameter: 48mm,or 56/58/60mm

Packaging & Delivery

In bulk or steel pallet. props will be bundle with wooden pallet or bare package in container one 20ft container can load steel props 1800pcs to 2500pcs.

20 to 30 days to main port of China after order confirmation

- Q: Are steel props suitable for supporting temporary walls or partitions?

- Temporary walls or partitions can be effectively supported by steel props. These props, also referred to as adjustable steel props or acro props, are commonly utilized in construction and building endeavors to provide temporary support to structures. Their primary function is to easily adjust their height, enabling flexibility in supporting different types of walls or partitions. Steel props possess a robust load-bearing capacity, allowing them to withstand heavy loads. This makes them highly suitable for supporting temporary walls or partitions. Typically constructed with high-quality steel, these props offer durability and stability to the structure they support. Moreover, their installation and dismantling processes are straightforward, making them convenient for temporary constructions. Additionally, steel props possess the advantage of adjustability, enabling precise height modifications to accommodate various wall or partition heights. This feature ensures that the temporary walls or partitions are adequately supported at the desired height, ultimately contributing to the overall stability and safety of the structure. To sum up, steel props are an ideal choice for supporting temporary walls or partitions due to their load-bearing capacity, durability, ease of installation, and adjustability. They provide the necessary support and stability required for temporary structures, making them a reliable solution in construction and building projects.

- Q: Can steel props be used in the construction of dams?

- Yes, steel props can be used in the construction of dams. Steel props, also known as steel supports or steel shoring, are commonly used in construction projects to provide temporary support to structures or excavations. In dam construction, steel props can be utilized during various stages of the project. During the excavation phase, steel props can be used to secure the sides of the excavation and prevent soil or rock collapse. This is crucial to ensure the safety of workers and maintain the stability of the site. Steel props can be adjusted and installed at different lengths to accommodate the specific requirements of the excavation. Additionally, steel props can also be used during the construction of the dam walls. They can be employed to support the formwork or molds used to shape the concrete walls of the dam. Steel props provide stability and strength to the formwork, allowing construction workers to pour and shape the concrete in a controlled manner. Moreover, steel props can be utilized during the maintenance or repair of dams. When certain sections of a dam need to be accessed for maintenance or repair work, steel props can be used to provide temporary support to the surrounding structures. This ensures the safety of workers and prevents any potential collapse or damage to the dam. Overall, steel props are versatile and reliable tools that can be effectively used in the construction of dams. They provide temporary support, stability, and safety, making them an essential component in the construction and maintenance of dams.

- Q: What are the different finishes available for steel props?

- There are several different finishes available for steel props, depending on the specific requirements and desired aesthetic. One common finish is galvanized steel, which involves applying a protective layer of zinc to the surface of the prop. This finish provides excellent corrosion resistance, making it suitable for outdoor applications or environments with high moisture levels. Galvanized steel props are also known for their durability and long lifespan. Another option is powder coating, which involves applying a dry powder to the surface of the prop and then curing it with heat. This finish offers a wide range of colors and textures, allowing for customization and versatility. Powder coating provides good resistance to chipping, scratching, and fading, making it a popular choice for both indoor and outdoor applications. For a more natural and rustic look, some steel props can be finished with a brushed or polished stainless steel surface. This finish enhances the aesthetic appeal of the prop, as it creates a sleek and reflective appearance. Stainless steel finishes are also highly resistant to corrosion, making them suitable for applications where hygiene and cleanliness are important, such as in the food industry or medical settings. Additionally, there are options for painted steel props, where a coat of paint is applied to the surface. This finish not only provides a decorative element but also helps to protect the steel from corrosion. Painted finishes can be customized to match specific color requirements or branding needs. Overall, the choice of finish for steel props depends on factors such as the intended use, environmental conditions, desired appearance, and budget. It is important to consider these factors and consult with professionals to select the most suitable finish for your specific requirements.

- Q: Can steel props be used in the installation of temporary safety barriers or guardrails?

- Yes, steel props can be used in the installation of temporary safety barriers or guardrails. Steel props are commonly used in construction and temporary works to support structures or elements that require additional stability. They provide a strong and stable support system, making them suitable for ensuring the safety and stability of temporary safety barriers or guardrails. Steel props can be adjusted to the desired height and can be easily installed and removed, making them a practical choice for temporary installations. Additionally, steel props are durable and can withstand heavy loads, ensuring the effectiveness and reliability of the safety barriers or guardrails.

- Q: Can steel props be used for temporary support during wall panel installation?

- Yes, steel props can be used for temporary support during wall panel installation. Steel props are commonly used in construction for temporary support due to their strength and stability. They can provide the necessary support to hold the wall panels in place during installation, ensuring safety and proper alignment.

- Q: Can steel props be used for supporting temporary amusement park rides or attractions?

- Yes, steel props can be used for supporting temporary amusement park rides or attractions. Steel is a strong and durable material that can provide the necessary stability and structural support required for such installations.

- Q: Can steel props be used in the construction of exhibition halls?

- Yes, steel props can be used in the construction of exhibition halls. Steel props, also known as adjustable steel props or acrow props, are commonly used in construction projects to provide temporary support to structures during construction or renovation. They are particularly useful in exhibition hall construction as they can be easily adjusted to the desired height, allowing for flexible installation and removal of walls, ceilings, and other temporary structures. Steel props are made of high-quality steel, which provides excellent strength and stability. They are designed to withstand heavy loads and provide reliable support, making them suitable for use in large-scale projects such as exhibition hall construction. Additionally, steel props are available in various sizes and weight capacities, allowing for customization to meet specific construction requirements. The use of steel props in exhibition hall construction offers several advantages. Firstly, they provide a cost-effective solution as they can be reused in different projects, reducing the need for frequent purchases. Secondly, their adjustable nature allows for quick and efficient installation, saving time and labor during the construction process. Furthermore, steel props offer versatility as they can support various types of structures, including walls, beams, and temporary stages. However, it is important to consult with structural engineers or construction professionals to ensure that the use of steel props is suitable for the specific exhibition hall project. They can assess the load-bearing requirements and provide guidance on the appropriate size and number of steel props needed for the construction. Additionally, local building codes and regulations should be considered to ensure compliance and safety. In conclusion, steel props can indeed be used in the construction of exhibition halls. Their strength, adaptability, and cost-effectiveness make them a viable option for providing temporary support during the construction or renovation of exhibition spaces.

- Q: How do steel props accommodate for changes in formwork dimensions?

- Steel props are commonly used in construction to provide temporary support to formwork during the concrete pouring process. They can easily be adjusted to fit changes in formwork dimensions. One way steel props adjust to changes in formwork dimensions is through their telescopic design. These props have an outer tube and an inner tube that can be extended or retracted to the desired height. The inner tube slides up or down within the outer tube when the locking mechanism is loosened, allowing for easy adjustment to fit the changed formwork dimensions. Once the desired height is reached, the locking mechanism is tightened to secure the prop in place. Moreover, steel props often have threaded end plates at the top and bottom. These plates can be rotated in either direction to further adjust the height of the prop. By turning the plates appropriately, the prop can be extended or retracted to accommodate changes in formwork dimensions. In addition, some steel props come with a fine adjustment mechanism. This mechanism enables precise height adjustments using a screw or ratchet mechanism. By turning the screw or using the ratchet, the prop can be adjusted in small increments to perfectly fit the changed formwork dimensions. Overall, steel props offer great flexibility in adapting to changes in formwork dimensions. Their telescopic design, threaded end plates, and fine adjustment mechanisms allow for easy and precise adjustments to ensure a secure and proper fit with the formwork, ultimately contributing to the success of the concrete pouring process.

- Q: How do steel props contribute to the overall cost of a construction project?

- Steel props can contribute to the overall cost of a construction project in several ways. Firstly, the cost of purchasing or renting steel props adds to the project's budget. Additionally, steel props require regular maintenance and inspection, which incurs ongoing costs. Moreover, their installation and removal involve labor expenses. However, steel props provide essential support and stability during construction, potentially reducing the risk of accidents or structural damage, which can ultimately save costs associated with repairs or delays.

- Q: How do you ensure stability on uneven or sloped surfaces when using steel props?

- To ensure stability on uneven or sloped surfaces when using steel props, it is important to use adjustable props with a base plate or foot plate. These plates provide a larger surface area for distribution of weight and help to prevent sinking or tipping. Additionally, adjusting the prop to the desired height and securing it tightly ensures a stable and secure foundation.

Send your message to us

Construction Heavy Duty Support Steel Props

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords