Slab Formwork System With Adjustable Prop Support System

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

suspended slab formwork

slab form work

concrete slab formwork

Waterproof Slab Formwork System With Adjustable Prop Table Formwork

Description:

1. Breif introduction

Especially for projects with a large number of similar applications and open facades, Alu-slab system is the right solution.

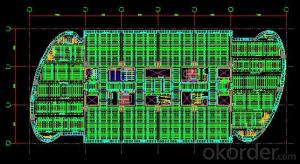

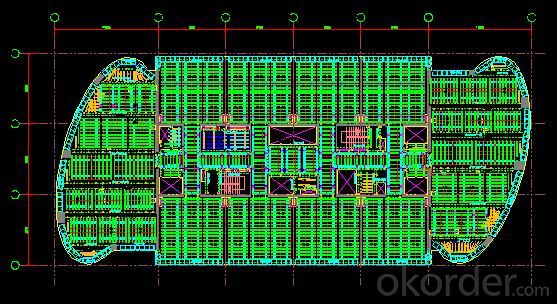

Here, table formwork is designed to suit a particular structure and is customised down to the last detail. If the geometry of the structure requires, for example, a trapezoidal-shaped table for a circular office building, the table system tailored solution is the right choice. Adapting to the shape of the structure means that infill areas are reduced to a minimum. We have to make all the formwork to slab.

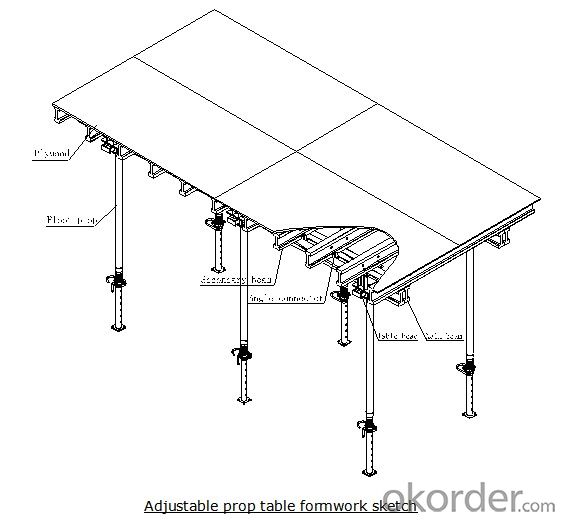

2. Structure of table formwork

3. About the infill areas

For RA-INST system, infill materials are necessary for small space or same special area. They are usually composed of timber beam, prop, head-jack, tripod, and plywood as the below picture shown.

4. Competitive advantage

① Fast construction

The table formwork is pre-assembled; all the structural elements are connected by specific fastenings, so it is easily to move and turnover.

②Easy operation

The formwork is composed of plywood, timber beam, table head and props. It’s easy to assemble for labors with simple structure. Special skill train is no needed.

③Props are adjustable

Table formwork is supported with adjustable props; the props can be pivoted in two directions for meeting the demand of different height.

④Mature system with several kinds of specific tools.

We afford trolley, lifting fork, handrail for TBS-A system, trolley is especially for shifting table formwork from the slab; lifting fork is a lifting tool for lifting the table formwork by crane; The workers will be in a safe site condition by means of handrail.

5. Applications

- Q: Plastic deformation of the template how to solve or why the deformation Thank you I want the reason

- Pvc plate deformation are: physical deformation and chemical deformation.A physical deformation, the cause:???? High temperature lead to deformation, if it is such a deformation, targeted plastic raw materials for high temperature modification, can effectively improve such problems???? Improper textile lead to deformation, such deformation has two reasons, a plate of raw materials can not meet the actual requirements of the product requirements, re-deployment of raw materials formula to meet the actual requirements of the product can be. Second, the processing and storage methods are not correct, leading to deformation, such problems can solve the problem from the rootTwo chemical deformation: mainly the molecular structure of raw materials change.

- Q: Plastic construction template has no one used? How about the effect of using. How much can the main savings? Can really use 50 times?

- By our site identification: hollow plastic building templates to protect the case of the use of 50 times is not a problem, even more than 50 times. Not capped Plastic non-stick cement. You know.

- Q: Why the floor is not plastic building materials square wood and template

- Is the plastic strong? The environment on the site you know, throw off how to do, have to find strong and durable.

- Q: Who used it, how not universal.

- The product has the following characteristics: 1. General product specifications 3020 * 1220 * (12-20) mm. Product area, construction joints less, improve the construction speed and efficiency. 2. The product can be sawed, planing, can be nailed, can be repaired, processing is very convenient. 3. Strong plastic PP plastic template does not absorb water, there is no stratification, cracking phenomenon.

- Q: I heard that there are building aluminum template and plastic template it? Which is better?

- Wood-plastic building templates in the construction works more useful, more affordable, more convenient.

- Q: Plastic mold dynamic template, the size of the template

- A lot of it? What are you talking about? Plastic mold points a lot of tonnage, there are 80T, 120T, 240T, 1000T, 1250T

- Q: I heard that plastic construction template workers do not want to use, there is such a situation

- Are generally wood board, plastic with less

- Q: Plastic building template made of what material

- Plastic template (that also can be said that the composite template)

- Q: Why is the building template made 1830mm * 915mm and not made 2000mm * 1000mm it?

- Can be ruled length processing, can be ruled length processing, can be ruled length processing

- Q: The price of raw materials can say better, is the PVC material.

- Usually in square meters. But whether by square meters or by weight count, but the process is different, but the results will be the same unit price. Off to know how much the cost of this product, how much profit. The cost of each product produced by the factory are not necessarily, of course, the profit is not the same. Cost is the material, management, plant rent, utilities, machine depreciation and other costs together, and now PVC materials have different grades, the specific price can be found on the Internet to see.

Send your message to us

Slab Formwork System With Adjustable Prop Support System

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords