Adjustable Steel Prop - Vertical Structure Support System

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

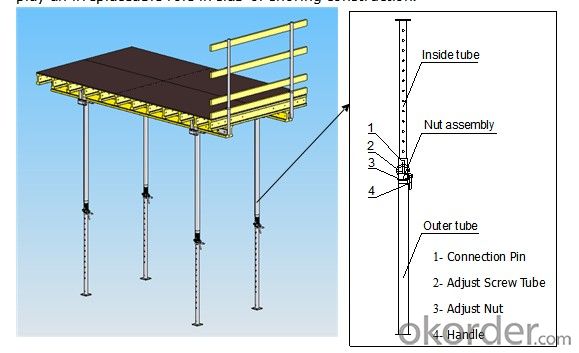

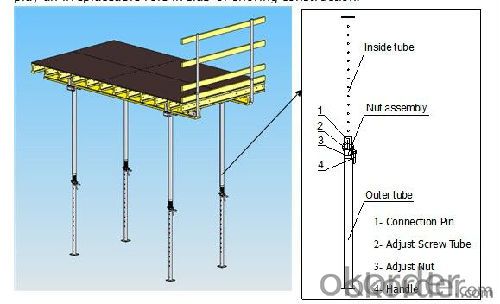

1. Structure of Adjustable Steel Prop

A vertical support system widely used in construction of slab or shoring. The prop has simple structure. It is easy to operation and has perfect adjustment to each individual job site requirement, all these features decide that the props play an irreplaceable role in slab or shoring construction.

2. Main Features of Adjustable Steel Prop

① Simple structure, easy operation.

As the above picture shown, the prop has very simple structure. The height of prop is adjustable by means of the relative position of inside tube and outer tube. And the light adjustment will be achieved by rotating adjust nut. It is very easy to operate for every labor.

②Reasonable load-bearing capacity.

The prop is mainly used for supporting slab formwork, especially for table formwork, its load-bearing capacity is undoubted important to be construction safety. The props have two series according to different load-bearing capacity: 30KN per set and 20KN per set with maximum height. Usually, we take 2 times safety factors in formwork design.

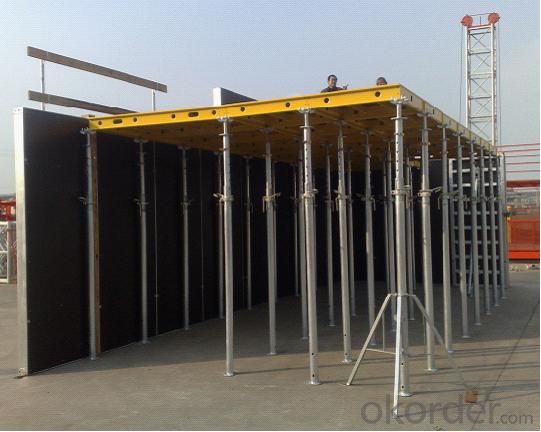

3. Adjustable Steel Prop Images

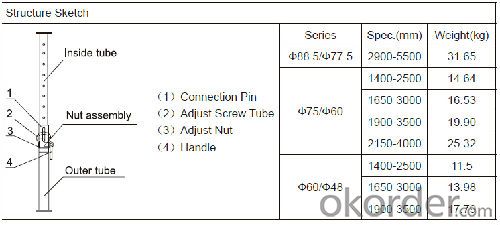

4. Adjustable Steel Prop Specification

5. FAQ of Adjustable Steel Prop

1) What can we do for you?

We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

We can provide you the professional design team.

We can provide fashionable and newest styles for you.

We can design the artwork for you.

Please feel free to customize.

2) What promises can be done by us?

If interested in Adjustable Steel Prop, please feel free to write us for any QUOTE.

If printing required, please advise asap because the whole set need much more time to complete.

Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

Response will be carried out in 24hours after receiving any complain or request.

If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

Packing: As Customer's Requirements

Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

Shipping time:Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days. Other mass qty of Adjustable Steel Prop, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: Can steel props be used in foundation repair work?

- Yes, steel props can be used in foundation repair work. Steel props are commonly used in construction and can provide the necessary support to stabilize and reinforce foundation structures during repair processes.

- Q: Can steel props be used in highway construction?

- Indeed, highway construction can make use of steel props. These support systems, known for their strength and durability, are widely employed in various construction ventures, including highway projects. During construction or repair work, steel props offer temporary support to structures like formwork, walls, or beams. Their adjustable height and straightforward installation and dismantling process make them a practical option for temporary support needs in highway endeavors. By ensuring stability and safety at the construction site, these props enable workers to carry out their tasks efficiently and securely.

- Q: Started to want to buy a good quality of the new steel support to go where ah

- The traditional template reinforcement system using wood plywood + + square steel tube, because the wood stiffness is small and making precision, steel and wood for the line of contact and other reasons, caused by the poor quality of concrete, yin and yang angle is not square, leakage, many quality problem of actual measurement standards etc..

- Q: How do you prevent rust on steel props?

- To prevent rust on steel props, it is important to keep them clean and dry. Applying a protective coating such as paint or a rust inhibitor can also help to create a barrier between the steel and moisture, reducing the chances of rust formation. Regular inspections and maintenance, including addressing any scratches or chips in the coating, can further prevent rust from developing on steel props.

- Q: What are the factors to consider when selecting steel props for a project?

- There are several important factors to take into account when choosing steel props for a project. First and foremost, it is crucial to assess the props' load-bearing capacity. The weight and size of the structure being supported should be considered to ensure that the props can bear the load adequately and without any risk of failure or collapse. This requires determining the maximum load capacity of the props and comparing it to the project's requirements. In addition, the height and adjustability of the props must be considered. The props need to reach the desired height and be adjustable to accommodate any changes in the project's requirements. This involves evaluating the available range of adjustment options, such as telescopic or screw-type props, and ensuring that they can be adjusted easily and safely. Another factor to take into consideration is the quality and durability of the steel props. It is important to choose props made from high-quality steel to ensure their strength, longevity, and resistance to corrosion. This can be determined by examining the material specifications, such as the grade of steel used and whether it meets relevant industry standards and certifications. Moreover, the ease of installation and dismantling should be taken into account. The props should be designed in a way that allows for quick and efficient assembly and disassembly, minimizing any potential disruptions to the project timeline. This could involve considering features such as self-locking mechanisms or snap-on parts. Lastly, the cost and availability of the steel props should be considered. It is important to select props that fit within the project's budget while still meeting the required specifications. Additionally, ensuring that the props are available from reliable suppliers is crucial to avoid any delays or complications during the project. In conclusion, considering factors such as load-bearing capacity, height and adjustability, quality and durability, ease of installation, and cost and availability will help in choosing the most suitable steel props for a project.

- Q: Can steel props be used in the construction of concert halls?

- Yes, steel props can be used in the construction of concert halls. Steel props are commonly used in construction projects to provide temporary support to structures. They are versatile, strong, and can be adjusted to accommodate different heights and loads. In the case of concert halls, steel props can be used to support the framework during construction or renovation phases, ensuring stability and safety.

- Q: Are steel props suitable for supporting temporary film sets?

- Yes, steel props are suitable for supporting temporary film sets.

- Q: How long can a steel prop be extended?

- The extension length of a steel prop is contingent upon several factors, including the prop's design, specifications, and intended purpose. In construction and temporary support systems, steel props, also known as adjustable steel props or steel shoring props, are commonly employed. Typically, manufacturers specify the maximum length to which a steel prop can be extended. This maximum length is determined by the prop's load-bearing capacity and its ability to provide adequate support. Adhering to the manufacturer's guidelines is crucial, as surpassing the maximum extension length jeopardizes the prop's structural integrity and safety. Steel props are adjustable, facilitating easy customization for different heights and requirements on construction sites. They usually incorporate a threaded mechanism that enables incremental extension and retraction to achieve the desired height. By rotating the thread, the prop can be gradually extended or shortened, granting flexibility in various applications. It is important to note that while steel props offer considerable strength and stability, their load-bearing capacity diminishes as they reach longer lengths. Therefore, the weight and load being supported must be taken into account when determining the appropriate extension length for a steel prop. To summarize, the maximum extension length of a steel prop hinges on its design, load-bearing capacity, and the manufacturer's specifications. By adhering to the manufacturer's guidelines and considering the weight and load requirements, one can safely extend a steel prop to the suitable length for temporary support in construction or other relevant applications.

- Q: RT, steel support (roof brace) 1 varieties of steel, round steel specifications: diameter 12, Q235B2 single weight: 0.3T3 sandblasting derusting grade Sa2.54 anti rust paint alkyd enamel two times, two times

- Steel support (steel brace) set the quota according to the corresponding types of steel to steel support (steel brace) production, installation, transportation, paint (anti rust paint over quota already contains quota). If the machine is rust, then set the corresponding mechanical rust removal (shot blasting rust and sand blasting rust, general drawing design instructions will be noted that manual rust has been included in the quota)

- Q: Can steel props be used in telecommunications tower construction?

- Yes, steel props can be used in telecommunications tower construction. Steel props are commonly used in construction projects to provide temporary support and stability to structures. In telecommunications tower construction, steel props can be used during the installation process to support the tower structure while it is being erected. They help ensure the tower remains stable and secure during the construction process.

Send your message to us

Adjustable Steel Prop - Vertical Structure Support System

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords