Steel Prop & Beam Clamp for building construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Prop & Tripod & Beam Clamp

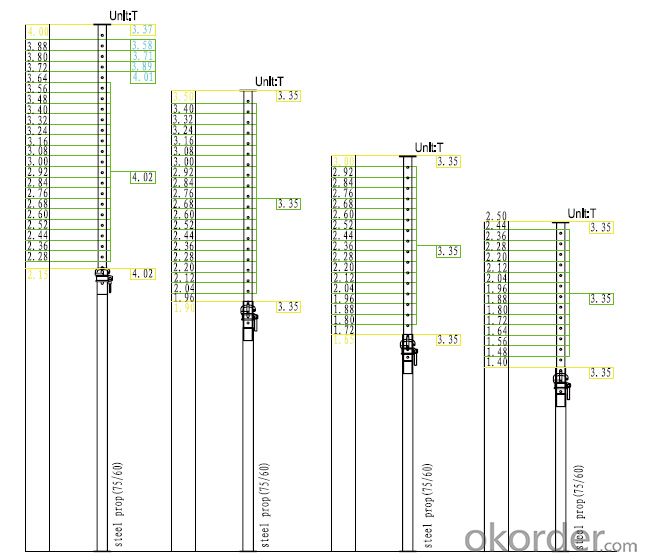

(1) Steel prop is a vertical support system widely used in construction.

Characteristics:

◆ Simple & flexible structure

◆ Easy & fast operation

◆ Economical efficiency

◆ Easy storage and transportation

◆ Reasonable load-bearing capacity

(2) Tripod is always used as support for steel prop.

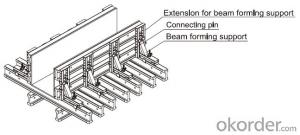

(3) The beam clamp is a technical instrument for supporting beam formwork

which makes conventional beam formwork simple, and increases the construction

efficiency.

Characteristics:

◆ Flexible structure

◆ Optimum design proposal

- Q: Are steel props suitable for supporting overhead cranes or gantries?

- Yes, steel props are suitable for supporting overhead cranes or gantries. Steel props are strong and durable, capable of providing the necessary support and stability required for heavy machinery like cranes and gantries.

- Q: Can steel props be used in warehouse construction?

- Warehouse construction can utilize steel props. These props, also known as adjustable steel props or scaffolding props, are commonly employed in construction endeavors to uphold vertical loads. They serve as temporary support during the construction process, particularly for formwork and scaffolding. In the context of warehouse construction, steel props can be employed to uphold hefty loads like roof beams, columns, and walls. They prove particularly useful in situations where supplementary support is necessary to guarantee the stability of the structure. Steel props can be conveniently adjusted to the desired height and can be used in various configurations to cater to the specific demands of the warehouse construction project. Furthermore, steel props present numerous advantages over alternative support systems. They possess the attributes of being lightweight, durable, and capable of enduring substantial loads. Additionally, they are versatile and can be effortlessly installed and disassembled, rendering them a cost-effective solution for provisional support in warehouse construction. Ultimately, steel props constitute a dependable and efficient choice for sustaining heavy loads in warehouse construction. Nonetheless, it is imperative to consult with a structural engineer or construction professional to ensure the proper and safe utilization of the props, in accordance with the project's distinct requirements.

- Q: What are the different types of steel used in steel props?

- There are several different types of steel used in steel props, including carbon steel, stainless steel, and alloy steel. Carbon steel is the most common type and is known for its strength and durability. Stainless steel is often used in applications where corrosion resistance is important. Alloy steel is a combination of different metals and is chosen for its specific properties, such as high strength or heat resistance.

- Q: Can steel props be used for temporary support in residential buildings?

- Yes, steel props can be used for temporary support in residential buildings. Steel props are commonly used in construction to provide temporary support during various stages of the building process. They are adjustable and can be easily installed to provide additional support to walls, beams, or other structural elements that may require extra reinforcement. Steel props are especially useful when there is a need to remove load-bearing walls or when constructing or renovating upper floors. However, it is important to ensure that the steel props are correctly installed and sized to withstand the load they are intended to support. It is also advisable to consult with a structural engineer or construction professional to determine the appropriate size and placement of steel props to ensure the safety and stability of the residential building during temporary support.

- Q: Are steel props suitable for supporting temporary medical facilities?

- Yes, steel props are suitable for supporting temporary medical facilities. Steel props, also known as adjustable steel props or acrow props, are commonly used in construction to support structures temporarily. They are strong, durable, and can bear significant weight, making them suitable for supporting various types of temporary structures, including medical facilities. Temporary medical facilities often require sturdy support systems to ensure the safety and stability of the structure. Steel props can be easily adjusted to the desired height and provide reliable support for the temporary walls, ceilings, and other structures necessary for medical facilities. Moreover, steel props are versatile and can be used in different configurations, allowing for flexibility in the layout and design of the temporary medical facility. They can be securely placed at various angles and adjusted to accommodate the specific needs of the facility. Additionally, steel props are easy to install and dismantle, making them ideal for temporary structures that may need to be moved or dismantled after a certain period. They can be quickly assembled and disassembled, saving time and effort during the construction and deconstruction process. In summary, steel props are suitable for supporting temporary medical facilities due to their strength, durability, versatility, and ease of installation. They provide the necessary stability and support required for temporary structures, ensuring the safety and functionality of the medical facility.

- Q: Can steel props be rented or leased?

- Yes, steel props can be rented or leased. Steel props, also known as adjustable steel props or acrow props, are commonly used in construction projects to provide temporary support to ceilings, walls, or other structures. These props are adjustable in height and can be easily installed and removed as needed. Many equipment rental companies offer steel props for rent or lease, allowing construction companies and individuals to access the required support equipment without having to purchase them outright. Renting or leasing steel props can be a cost-effective solution for short-term projects or when purchasing the props is not feasible or necessary.

- Q: Can steel props be used in different weather conditions?

- Yes, steel props can be used in different weather conditions. Steel is a strong and durable material that can withstand various weather conditions such as rain, wind, and extreme temperatures. However, it is important to ensure proper maintenance and protection to prevent rust and corrosion that can be caused by prolonged exposure to harsh weather elements.

- Q: Can steel props be used in the construction of manufacturing facilities?

- Yes, steel props can be used in the construction of manufacturing facilities. Steel props are commonly used in construction projects to provide temporary support to structures during the construction process. They are versatile, strong, and can be easily adjusted to support different loads and heights. Therefore, steel props can be effectively used in the construction of manufacturing facilities to ensure stability and safety during the building process.

- Q: RT, steel support (roof brace) 1 varieties of steel, round steel specifications: diameter 12, Q235B2 single weight: 0.3T3 sandblasting derusting grade Sa2.54 anti rust paint alkyd enamel two times, two times

- Steel support (steel brace) set the quota according to the corresponding types of steel to steel support (steel brace) production, installation, transportation, paint (anti rust paint over quota already contains quota). If the machine is rust, then set the corresponding mechanical rust removal (shot blasting rust and sand blasting rust, general drawing design instructions will be noted that manual rust has been included in the quota)

- Q: How do steel props contribute to the overall sustainability of construction practices?

- Steel props contribute to the overall sustainability of construction practices by offering a reusable and durable support system for temporary structures. They help reduce the need for excessive excavation and concrete usage, leading to reduced material waste and lower environmental impact. Additionally, their adjustable design allows for efficient use of resources by adapting to different project requirements, minimizing the need for additional materials and reducing overall construction time.

Send your message to us

Steel Prop & Beam Clamp for building construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords