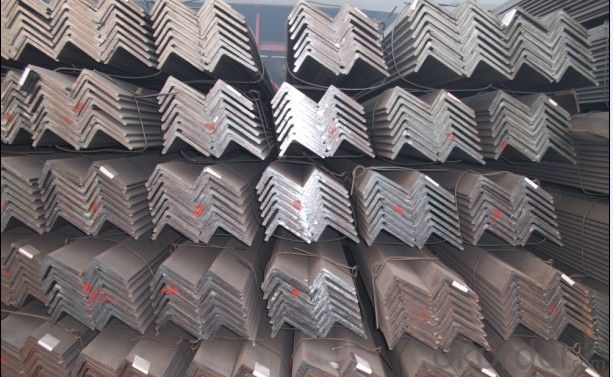

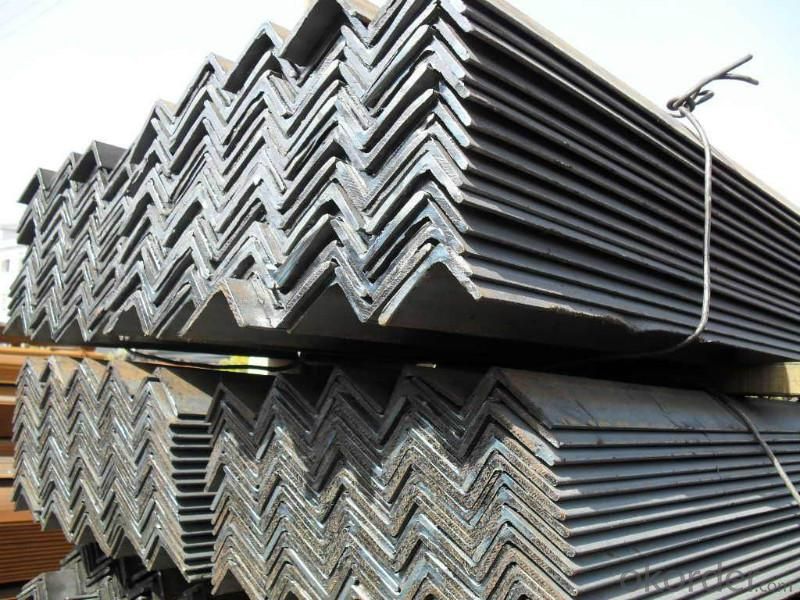

Unequal Steel Angle Mild Hot Rolled Low Carbon Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 24000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering Unequal Steel Angle Mild Hot Rolled Low Carbon Steel at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Unequal Steel Angle Mild Hot Rolled Low Carbon Steel are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Unequal Steel Angle Mild Hot Rolled Low Carbon Steel are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Trademark | Rank | Chemical composition (quality score) % | |||||

C | Si | Mn | S | P | |||

≤ | ≤ | ≤ | |||||

Q235 | A | 0.14-0.22 | 0.30 | 0.30-0.65 | 0.050 | 0.045 | |

Q235 | B | 0.12-0.20 | 0.30 | 0.30-0.70 | 0.045 | 0.045 | |

Trademark | Rank | Pulling Test | |||||

Bend PointΔs/Mpa | Tensile Strength | Elongation Ratioδ5% | |||||

Thickness (Diameter) /MM | Thickness (Diameter) /MM | ||||||

≤16 | 16-40 | ≤16 | 16-40 | ||||

≥ | ≥ | ||||||

Q235 | A | 235 | 225 | 375-500 | 26 | 25 | |

Q235 | B | 235 | 225 | 375-500 | 26 | 25 | |

| UNEQUAL ANGLE STEEL | |||||

| size(mm) | a(mm) | a1(mm) | thickness(mm) | kg/m | length(m) |

| 75*50*5 | 75 | 50 | 5 | 4.808 | 6m,9m,12m |

| 75*50*6 | 75 | 50 | 6 | 5.699 | 6m,9m,12m |

| 75*50*8 | 75 | 50 | 8 | 7.431 | 6m,9m,12m |

| 100*75*7 | 100 | 75 | 7 | 9.34 | 6m,9m,12m |

| 100*75*8 | 100 | 75 | 8 | 10.6 | 6m,9m,12m |

| 100*75*9 | 100 | 75 | 9 | 11.8 | 6m,9m,12m |

| 100*75*10 | 100 | 75 | 10 | 13 | 6m,9m,12m |

| 100*75*12 | 100 | 75 | 12 | 15.4 | 6m,9m,12m |

| 125*75*7 | 125 | 75 | 7 | 10.7 | 6m,9m,12m |

| 125*75*8 | 125 | 75 | 8 | 12.2 | 6m,9m,12m |

| 125*75*9 | 125 | 75 | 9 | 13.6 | 6m,9m,12m |

| 125*75*10 | 125 | 75 | 10 | 15 | 6m,9m,12m |

| 125*75*12 | 125 | 75 | 12 | 17.8 | 6m,9m,12m |

| 150*90*8 | 150 | 90 | 8 | 14.7 | 6m,9m,12m |

| 150*90*9 | 150 | 90 | 9 | 16.4 | 6m,9m,12m |

| 150*90*10 | 150 | 90 | 10 | 18.2 | 6m,9m,12m |

| 150*90*12 | 150 | 90 | 12 | 21.6 | 6m,9m,12m |

| 200*100*10 | 200 | 100 | 10 | 23 | 6m,9m,12m |

| 200*100*12 | 200 | 100 | 12 | 27.62 | 6m,9m,12m |

| 200*100*15 | 200 | 100 | 15 | 34.04 | 6m,9m,12m |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The normal sizes with the normal grade can be produced within one month. The specific shipping date is dependent upon international and government factors, the delivery to international main port about 45-60days.

Q4: How many tons of steel products could be loaded in containers?

A4: Usually the steel products are delivered by bulk vessel because of the large quantity and the freight. However, there are no bulk vessel enter some seaports so that we have to deliver the cargo by containers. The 6m steel product can be loaded in 20FT container, but the quantity is changed according to the size, usually from 18tons to 25tons.

Images:

- Q: Can steel angles be used for framing in residential construction?

- Yes, steel angles can be used for framing in residential construction. Steel angles are commonly used as structural elements in construction due to their strength and durability. They can be used to provide support and stability in various framing applications such as wall framing, roof trusses, and floor joists. Steel angles offer several advantages in residential construction, including their resistance to warping, shrinking, and rotting, making them a reliable choice for framing. Additionally, steel angles are fire-resistant, which adds an extra layer of safety in residential buildings. Overall, steel angles are a versatile and cost-effective option for framing in residential construction projects.

- Q: How do you cut steel angles?

- There are various techniques available for cutting steel angles, depending on their thickness and size. One popular approach involves using metal cutting saws like metal chop saws or band saws. These saws are specifically designed for cutting through metal and possess the necessary power and cutting capacity for steel angles. Prior to cutting, it is essential to securely fasten the steel angle in place using clamps or a vice to prevent any movement during the cutting process. This ensures precise and clean cuts. It is also advisable to wear appropriate safety equipment, including safety glasses and gloves, as cutting steel can generate sharp metal chips. If utilizing a metal chop saw, you can adjust the saw's angle to match the angle you wish to cut. Be sure to set the blade speed and feed rate according to the manufacturer's recommendations for steel cutting. Gradually lower the blade onto the steel angle, applying consistent pressure to achieve a smooth and accurate cut. When employing a band saw, make sure to install the suitable blade for cutting metal. Adjust the blade tension and guide settings as per the manufacturer's instructions. Slowly feed the steel angle into the saw, maintaining a steady pace to obtain a clean cut. It is important to note that band saws may generate more heat during cutting, so periodically applying a coolant lubricant can prevent overheating and prolong the blade's lifespan. For thicker and larger steel angles, plasma cutting or oxy-fuel cutting methods can be employed. These methods involve using high-temperature flames or a plasma arc to melt through the steel. However, operating these techniques safely requires specialized equipment and expertise. Irrespective of the cutting method used, it is crucial to accurately measure and mark the intended cut line before commencing the cutting process. This guarantees that the steel angle is cut to the correct dimensions. Additionally, it is recommended to practice on scrap pieces of steel before attempting to cut the actual steel angle. This helps familiarize oneself with the cutting process and ensures desired outcomes.

- Q: Can steel angles be used in sign support structures?

- Yes, steel angles can be used in sign support structures. Steel angles are commonly used in construction due to their high strength and durability. They provide excellent support and stability, making them suitable for a wide range of applications, including sign support structures. Steel angles can be easily welded or bolted together to create a sturdy framework for mounting signs. They also have a high load-bearing capacity, which is essential for ensuring the sign remains secure and stable, even in adverse weather conditions. Additionally, steel angles can be customized to suit specific design requirements, making them a versatile choice for sign support structures.

- Q: Can steel angles be used for electrical conduits or cable trays?

- Depending on project requirements and regulations, steel angles can serve as support structures for electrical conduits or cable trays. These angles are well-known for their strength and durability, making them commonly used as structural supports. However, when considering their use for electrical conduits or cable trays, it is imperative to ensure that they meet the necessary electrical and safety codes. Electrical conduits and cable trays are specifically designed to house and protect electrical wires or cables in a safe manner. These systems must be capable of withstanding the weight of the cables, providing proper grounding, and offering sufficient protection against physical damage, moisture, and other potential hazards. Steel angles can be employed as support structures for electrical conduits or cable trays, providing a robust framework for the installation and securement of the system. However, it is crucial to ensure that the steel angles are effectively grounded, insulated, and guarded against corrosion to meet all electrical safety standards. Furthermore, the selection of the appropriate size and dimensions for the steel angles should be based on the weight and size of the cables or wires being installed. To guarantee compliance with all necessary requirements, it is important to consult with electrical engineers or professionals who are familiar with local electrical codes and standards. In conclusion, while steel angles can be utilized for electrical conduits or cable trays, it is essential to carefully consider the specific requirements and regulations of the project to ensure electrical safety and compliance.

- Q: Can steel angles be used in modular construction or prefabricated structures?

- Yes, steel angles can be used in modular construction or prefabricated structures. Steel angles are commonly used as structural components in these types of construction due to their strength, versatility, and ability to be easily fabricated and assembled. They provide stability and support to the overall structure, making them a suitable choice for modular and prefabricated construction methods.

- Q: Can steel angles be used for retaining walls?

- Steel angles are a viable option for retaining walls. In construction, steel angles are commonly employed for a variety of purposes, including supporting structures and constructing retaining walls. They offer stability and strength to the wall, making them suitable for retaining soil or other substances. Steel angles can serve as the primary structural element or be combined with materials like concrete or timber to create a durable and robust retaining wall. The specific factors to consider in the design and engineering process would be the wall's height, load requirements, soil conditions, and local building codes. However, when properly designed and installed, steel angles can prove to be an effective choice for retaining walls.

- Q: What is the maximum load capacity for a curved steel angle?

- The maximum load capacity of a curved steel angle is influenced by several factors, including the angle's dimensions and thickness, the quality of the steel, and the specific application. Typically, structural engineering calculations and analysis are used to determine the load capacity. These calculations consider the steel's material properties, the angle's curvature, and any additional forces or loads it will experience. To establish the maximum load capacity for a particular curved steel angle in a specific application, it is crucial to seek guidance from a qualified structural engineer or consult relevant design codes and standards.

- Q: Are steel angles resistant to termites and pests?

- No, steel angles are not resistant to termites and pests. Steel angles, being made of metal, are not attractive to termites as they do not provide a food source. However, termites can still cause damage to surrounding materials such as wood or insulation, which may be present in the structure where the steel angles are used. It is important to ensure that the overall construction is termite-resistant and appropriate measures are taken to prevent infestations.

- Q: How are steel angles protected against abrasion?

- Steel angles find common applications in construction and industrial settings, where they are exposed to various forms of abrasion. To safeguard steel angles against abrasion, multiple techniques are employed. One prevalent approach involves the use of protective coatings, such as paints, epoxy coatings, or specialized coatings designed for abrasion resistance. These coatings act as a barrier between the steel surface and abrasive elements, preventing direct contact and minimizing wear caused by friction. Another method entails the application of rubber or plastic linings to the susceptible surfaces of steel angles. These linings absorb the impact of abrasive forces, cushioning the steel and reducing wear. Additionally, they provide an extra layer of protection against corrosion and chemical attacks. In certain cases, steel angles may undergo hardening or heat treatment. This process involves subjecting the steel to high temperatures followed by rapid cooling, altering the steel's microstructure to enhance hardness and resistance to abrasion. Heat-treated steel angles are commonly used in industries with high-wear environments, such as mining and material handling. Furthermore, engineers may choose to design steel angles with specific profiles or shapes that offer improved resistance to abrasion. These profiles may include rounded edges, chamfers, or other features that minimize direct contact with abrasive materials. Overall, protecting steel angles from abrasion involves a combination of protective coatings, linings, heat treatment, and thoughtful design. Implementing these measures significantly prolongs the lifespan and performance of steel angles, reducing maintenance costs and ensuring durability in abrasive environments.

- Q: What are the safety precautions when working with steel angles?

- When working with steel angles, it is important to follow a few safety precautions. Firstly, always wear appropriate personal protective equipment (PPE) such as safety glasses, gloves, and steel-toed boots to protect yourself from potential injuries. Secondly, ensure that the work area is clear of any obstructions or tripping hazards to prevent accidents. Additionally, make sure to use proper lifting techniques or equipment when handling heavy steel angles to avoid strains or back injuries. Lastly, be cautious of sharp edges and corners on the steel angles and use appropriate tools and techniques to prevent cuts or abrasions.

Send your message to us

Unequal Steel Angle Mild Hot Rolled Low Carbon Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 24000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords