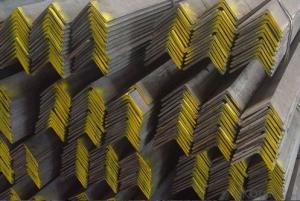

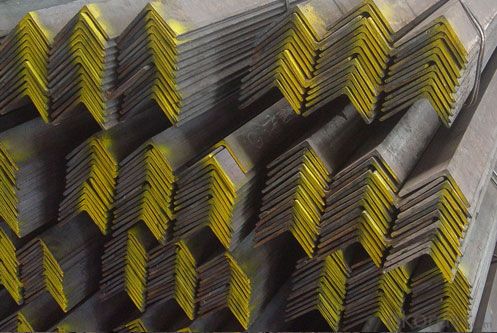

Unequal Angle Steel Hot Rolled Unequal Perforated Steel Angle Iron

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Unequal Angle Steel Hot Rolled Unequal Perforated Steel Angle Iron at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Unequal Angle Steel Hot Rolled Unequal Perforated Steel Angle Iron are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Unequal Angle Steel Hot Rolled Unequal Perforated Steel Angle Iron are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Hot Rolled Equal and Unequal perforated Steel Angle Iron

1.Standard: GB,ASTM,JIS

2.Steel Grade:Q195-Q420

3.Length: 5.8-12mm

Hot Rolled Unequal perforated Steel Angle Iron

| ||

Thickness | 12mm | |

3mm-25mm | 20mm-200mm | |

Length

| 5.8-12M , according to customers' requirements | |

Standard

| GB,JIS,ASTM,EN,DIN | |

Material

| 304 304L 316 321 | |

Type | Equal and unequal | |

Usage

| constructions,communication towers and so on. | |

Certification

| ISO9001,ISO9002,API | |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q: How many kilograms per square meter is angle steel 63*63*6?

- Angle gaugeCalculation method of angle weight:Weight per meter =0.00785* (edge width + edge width - side thickness) * edge thicknessEquilateral angle steel, kg/m equal angle steel, kg/m equal angle steel, kg/m25*3 1.124, 70*8 8.373, 110*12 19.78225*4 1.459, 75*5 5.818, 110*14 22.80930*3 1.373, 75*6 6.905, 120*10 18.20030*4 1.786, 75*7 7.976, 120*12 21.60040*3 1.852, 75*8 9.030, 125*8 15.504

- Q: Can steel angles be used for manufacturing safety barriers?

- Indeed, safety barriers can be manufactured using steel angles. In construction projects, steel angles are frequently utilized owing to their robustness and longevity. Specifically for safety barriers, they offer a firm framework that can endure impacts and offer protection. By welding or bolting steel angles together, a solid and secure barrier can be created effortlessly. Furthermore, by galvanizing or coating steel angles with anti-corrosive substances, their lifespan and resistance against environmental factors can be enhanced. In summary, steel angles are an exceptional option for manufacturing safety barriers due to their strength, durability, and versatility.

- Q: What is the minimum thickness for a steel angle beam?

- The minimum thickness of a steel angle beam is determined by several factors, including the load it needs to support, beam length, and the specific steel grade used. Typically, structural engineers or professionals in the field determine the minimum thickness based on the specific application and design requirements. Steel angle beams find common usage in construction, framing, and various structural applications. They are designed to provide stability and support, particularly in load-bearing situations. The thickness of the steel angle beam is crucial as it ensures its strength and ability to bear the intended load without any deformation or failure. Engineers consider several factors, such as the maximum load, beam length, steel material properties, and the required safety factor for the application, to determine the minimum thickness. Through mathematical calculations and structural analysis, they establish the appropriate thickness that fulfills the necessary structural requirements. It is important to note that specific industry standards and building codes must be adhered to when designing and constructing steel angle beams. These standards provide guidelines and requirements for minimum thickness, tolerances, dimensions, and connection details. Hence, it is always advisable to consult a qualified structural engineer or professional in the field to determine the minimum thickness of a steel angle beam based on the project's specific requirements. They consider all relevant factors and ensure that the beam is designed and constructed to provide the required strength and safety.

- Q: How does the price of steel angles vary based on size and grade?

- The price of steel angles can be affected by various factors, including the size and grade of the steel. When it comes to the size, larger angles are generally more expensive than smaller ones. This is because larger angles require more raw material and involve more manufacturing processes, resulting in higher production costs. As a result, as the size or length of the angle increases, so does its price. The grade of the steel also plays a role in determining the price. Steel angles come in different grades, each with its own characteristics and properties. Higher-grade steel angles, such as stainless steel or structural steel, tend to be more expensive compared to lower-grade options like mild steel. This is because higher-grade steels often require more advanced manufacturing techniques and superior quality raw materials, which contribute to higher production costs and, consequently, a higher price. Other factors that can impact the price of steel angles include market demand, the availability of raw materials, and manufacturing efficiency. Fluctuations in demand and supply can lead to price variations, with higher demand usually resulting in higher prices. Additionally, the availability and cost of raw materials used in the production of steel angles, such as iron ore and scrap metal, can affect the overall price. Lastly, advancements in manufacturing processes and technology can increase efficiency, potentially lowering production costs and influencing the final price of steel angles. To summarize, the price of steel angles is influenced by their size and grade. Larger angles and higher-grade steels tend to be more expensive due to increased production costs. Market demand, raw material availability, and manufacturing efficiency also play a role in determining the price of steel angles.

- Q: Can steel angles be used as structural members?

- Certainly, structural members can utilize steel angles. In construction and engineering endeavors, steel angles are frequently employed to furnish structural reinforcement and stability. They are commonly utilized to fortify and enhance an assortment of structures, including edifices, bridges, and frameworks. Renowned for their robustness and endurance, steel angles are highly suitable for structural applications. They can be utilized either in combination with other steel components or independently to bear or distribute loads, bolster beams, and confer stability to the overall structure. Moreover, steel angles can be conveniently fabricated and installed, rendering them a versatile and cost-effective choice for structural members in diverse construction projects.

- Q: Are steel angles suitable for earthquake-resistant construction?

- Yes, steel angles are suitable for earthquake-resistant construction. Steel angles have high strength and stiffness, which enables them to withstand the lateral forces and dynamic loads generated during an earthquake. They can be used in various structural elements, such as moment-resisting frames and bracing systems, to provide stability and resistance against seismic forces. Additionally, steel angles can be easily fabricated and installed, making them a popular choice in earthquake-resistant construction.

- Q: Are there any environmental concerns related to the production or disposal of steel angles?

- There exist numerous environmental concerns in relation to the production and disposal of steel angles. To begin with, the production of steel angles necessitates substantial amounts of energy and raw materials, such as iron ore and coal. The extraction of these resources can result in detrimental effects on the environment, including habitat destruction, deforestation, and air and water pollution. Furthermore, the manufacturing process itself emits greenhouse gases and other pollutants, contributing to climate change and air pollution. Moreover, the disposal of steel angles can pose problems. Steel is not easily biodegradable and may take hundreds of years to decompose. Inadequate disposal methods, such as landfilling or incineration, can lead to the release of toxic substances and contribute to soil and water contamination. To address these environmental concerns, various measures can be implemented. Firstly, enhancing the efficiency of steel production processes can reduce energy consumption and emissions. The utilization of recycled steel in the production of steel angles can also aid in decreasing the demand for raw materials and minimizing environmental impacts. Additionally, the implementation of proper waste management and recycling programs can help minimize the environmental footprint of steel angle disposal. In conclusion, although steel angles are crucial in numerous industries and construction, their production and disposal can have significant environmental implications. It is vital to prioritize sustainable practices and technologies to mitigate these concerns and promote a more environmentally friendly approach to the production and disposal of steel angles.

- Q: What are the different types of steel angles used in manufacturing?

- There are several different types of steel angles used in manufacturing, each with its own unique characteristics and applications. Some common types include: 1. Equal Angle: This type of steel angle has equal sides and angles, forming a 90-degree angle. It is commonly used for structural applications, such as framing and supports, where strength and stability are important. 2. Unequal Angle: As the name suggests, this type of steel angle has unequal sides and angles. It is often used for applications that require varying load-bearing capacities or to create different shapes in manufacturing processes. 3. L-Angle: Also known as L-shaped angles, this type of steel angle has a 90-degree bend with unequal sides. It is commonly used for reinforcing corners, as well as in construction and fabrication projects. 4. T-Angle: T-angles have a T-shaped cross-section, with one side extending vertically and the other extending horizontally. They are often used as structural supports or in applications where additional strength and rigidity are needed. 5. Flat Bar Angle: This type of steel angle has a flat surface on one side and a right-angle bend on the other. It is commonly used for bracing, supports, and framing in manufacturing and construction projects. 6. Slotted Angle: Slotted angles have holes or slots along their length, allowing for easy adjustment and customization. They are often used for shelving, racks, and storage systems in manufacturing and warehouse environments. These are just a few examples of the different types of steel angles used in manufacturing. The specific type of angle chosen will depend on the requirements of the project, including load-bearing capacity, structural integrity, and the desired shape or configuration.

- Q: How do steel angles perform in chemical industry applications?

- Due to their exceptional performance in corrosive environments, steel angles are extensively utilized in the chemical industry. These angles, composed of high-strength steel, demonstrate outstanding resistance to chemicals, acids, and other corrosive substances commonly encountered in the chemical industry. In the chemical industry, various chemicals are frequently handled and processed, which can lead to the corrosion and degradation of structural materials. Steel angles, with their high resistance to corrosion, offer a dependable and long-lasting solution in such environments. Additionally, steel angles provide excellent load-bearing capacity and structural stability, making them ideal for supporting heavy equipment, tanks, and platforms in chemical plants. Their versatility permits the construction of diverse structures and equipment, ensuring the safe and efficient operation of chemical processes. Steel angles can be manufactured in various sizes and shapes, allowing for effortless customization to meet specific requirements. This adaptability renders them suitable for a wide array of applications such as piping systems, storage tanks, chemical reactors, and support structures. Furthermore, steel angles are cost-effective in addition to their corrosion resistance and structural strength. They have a lengthy lifespan, necessitate minimal maintenance, and can endure extreme temperatures, pressures, and chemical exposures. This durability and low maintenance requirement contribute to the reduction of downtime and overall operating costs in the chemical industry. In conclusion, steel angles exhibit exceptional performance in chemical industry applications by offering a combination of corrosion resistance, structural strength, versatility, and cost-effectiveness. Their ability to withstand harsh chemical environments makes them an indispensable component in the safe and efficient operation of chemical processes.

- Q: What is the weight of a steel angle?

- The weight of a steel angle depends on its dimensions and density. To calculate the weight, one needs to know the length, width, and thickness of the steel angle. By multiplying the volume of the angle (length x width x thickness) by the density of steel, one can determine its weight. The density of steel is typically around 7.85 grams per cubic centimeter. Therefore, the weight of a steel angle can be calculated using the formula: weight = volume x density.

Send your message to us

Unequal Angle Steel Hot Rolled Unequal Perforated Steel Angle Iron

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords