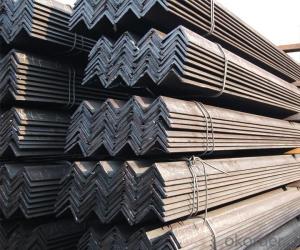

Unequal Steel Angle Hot Selling Various High Quality, Angle Steel, Angle Bars

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Unequal Steel Angle Hot Selling Various High Quality Angle Steel Angle Bars at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Unequal Steel Angle Hot Selling Various High Quality, Angle Steel, Angle Bars are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Unequal Steel Angle Hot Selling Various High Quality, Angle Steel, Angle Bars are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

1 .Materials:Q195/ Q235/ Q345/ ST-37/ ST-52/ SS400/ S235JR/ S275JR

2. Standard: ASTM,AISI, BS, DIN, GB, JIS

3. Type:Equal angle and Unequal

4.Size:20-200mm 75*50mm-200*100mm L:6-12m or cut as your request

| Unequal Angle | |||||||||

| Specification(mm) | Theoretical Weight(kg/m) | Specification(mm) | Theoretical Weight(kg/m) | ||||||

| 75*50*6 | 5.67 | 125*75*7 | 10.7 | ||||||

| 75*50*8 | 7.35 | 125*75*8 | 12.2 | ||||||

| 100*75*6 | 8.04 | 125*75*9 | 13.6 | ||||||

| 100*75*7 | 9.32 | 125*75*10 | 15 | ||||||

| 100*75*8 | 10.6 | 125*75*12 | 17.8 | ||||||

| 100*75*9 | 11.8 | 150*90*9 | 16.4 | ||||||

| 100*75*10 | 13 | 150*90*10 | 18.2 | ||||||

| 100*75*12 | 15.4 | 150*90*12 | 21.5 | ||||||

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

- Q: How do steel angles contribute to the overall stability of a structure?

- The overall stability of a structure is significantly influenced by steel angles, which serve multiple purposes. Primarily, steel angles are widely used as structural members in various applications, including building frames, bridges, and towers. Their L-shaped profile offers exceptional strength and load-bearing capabilities, making them ideal for supporting heavy loads and resisting bending or buckling. An important role of steel angles is to provide structural support and stability by distributing the load evenly across different components of the structure. By connecting elements like beams, columns, and girders, steel angles effectively transfer and resist weight and forces acting on the structure, thereby preventing potential collapse or failure. Furthermore, the overall rigidity and stiffness of a structure are enhanced by steel angles. When diagonal bracing elements made of steel angles are added, the structure becomes more resistant to lateral forces such as wind or earthquakes. These diagonal braces create a stable triangular configuration capable of withstanding horizontal loads. Consequently, the increased stability and resistance to lateral forces greatly contribute to the overall safety and durability of the structure. In addition, steel angles play a crucial role in mitigating torsional forces in a structure. Torsion occurs when one end of a structural member is twisted while the other end remains fixed, resulting in a twisting moment being applied to the structure. To counteract these torsional forces, steel angles can be strategically placed and connected, preventing excessive twisting or deformation that could jeopardize the structure's stability. To summarize, steel angles are vital components that contribute to the overall stability of a structure through various means. They offer structural support, efficiently distribute loads, enhance rigidity, resist lateral forces, and mitigate torsional forces. By incorporating steel angles into the design and construction of a structure, engineers can ensure its long-term stability, safety, and durability.

- Q: Can steel angles be used in telecommunications or broadcasting structures?

- Yes, steel angles can be used in telecommunications or broadcasting structures. Steel angles are commonly used in construction due to their strength, durability, and versatility. They can provide structural support and stability to various components of telecommunications and broadcasting structures, such as antenna mounts, equipment racks, and cable trays. Additionally, steel angles can be easily fabricated and customized to meet specific design requirements, making them suitable for a wide range of applications in the telecommunications and broadcasting industry.

- Q: Are steel angles suitable for architectural sculptures or installations?

- Yes, steel angles are suitable for architectural sculptures or installations due to their versatility, strength, and structural integrity. They can be easily shaped and welded to create intricate designs and support heavy structures, making them a popular choice for artistic and functional installations in architecture.

- Q: What are the common surface treatments used for steel angles?

- The common surface treatments used for steel angles are galvanizing, painting, and powder coating. Galvanizing is a process where a layer of zinc is applied to the surface of the steel angle to protect it from corrosion. This is achieved by immersing the steel angle in a bath of molten zinc or by applying a zinc coating using a specialized technique. Galvanized steel angles have a shiny, silver appearance and provide excellent corrosion resistance. Painting is another commonly used surface treatment for steel angles. The steel angle is typically primed and then coated with one or more layers of paint. This not only enhances the aesthetic appeal of the steel angle but also provides a protective barrier against rust and other environmental factors. Painting allows for a wide range of color options and finishes, making it a versatile choice for various applications. Powder coating is a dry finishing process where a fine powder, typically made of resin and pigment, is electrostatically applied to the steel angle's surface. The angle is then heated, causing the powder to melt and form a durable coating. Powder coating offers excellent resistance to scratches, chemicals, and UV rays. It is available in a wide array of colors and provides a smooth and even finish. The choice of surface treatment for steel angles depends on the specific application and the desired level of protection, aesthetics, and durability. Galvanizing is preferred in outdoor or corrosive environments, while painting and powder coating are commonly used for indoor applications or where a specific color or finish is desired.

- Q: What are the benefits of using hot-rolled steel angles?

- Hot-rolled steel angles offer several benefits, including high strength and durability, excellent structural integrity, and cost-effectiveness. They are ideal for various construction and manufacturing applications, providing stability and support in building frames, bridges, and machinery. Additionally, their malleability allows for easy fabrication and customization, making them a versatile choice for architects and engineers.

- Q: What are the typical lifespan and durability of steel angles?

- The typical lifespan and durability of steel angles can vary depending on various factors such as the quality of the steel, the environment in which they are used, and the level of maintenance they receive. However, steel angles are known for their excellent durability and long lifespan. In general, steel angles are designed to withstand heavy loads and provide structural support in various construction and industrial applications. They are commonly made from carbon steel or stainless steel, both of which are known for their strength and resistance to corrosion. When properly maintained and protected against corrosion, steel angles can last for several decades without significant deterioration. Regular maintenance practices such as cleaning, painting, and applying protective coatings can help extend their lifespan even further. The durability of steel angles is also influenced by the environment in which they are installed. In harsh environments with high levels of moisture, extreme temperatures, or exposure to chemicals, the lifespan may be shorter. However, proper corrosion protection measures can mitigate these effects and ensure a longer lifespan. It is worth noting that steel angles used in marine or offshore applications may have a shorter lifespan compared to those used in less corrosive environments. This is due to the constant exposure to saltwater and harsh weather conditions, which can accelerate corrosion. In summary, steel angles are known for their durability and can have a long lifespan if properly maintained and protected against corrosion. However, the specific lifespan can vary depending on factors such as the quality of the steel, environmental conditions, and maintenance practices.

- Q: What are the different types of steel angles used in transmission towers?

- There are primarily three types of steel angles used in transmission towers: equal leg angles, unequal leg angles, and back-to-back angles.

- Q: Can steel angles be used in telecommunications tower constructions?

- Telecommunications tower constructions can utilize steel angles. These angles are frequently employed as structural elements in diverse construction projects, such as telecommunications towers. Their utilization imparts the tower with robustness, stability, and assistance. By welding or bolting steel angles together, a solid and long-lasting framework is formed, capable of enduring the tower's weight and equipment. Moreover, steel angles can be conveniently customized and fabricated to satisfy the precise design and engineering prerequisites of the telecommunications tower.

- Q: Are steel angles suitable for mezzanine floors?

- Indeed, steel angles prove to be a fitting choice for constructing mezzanine floors. Their robustness, longevity, and affordability render them a prevalent choice in mezzanine floor construction. By delivering structural reinforcement and steadiness, steel angles facilitate the expansion of floor area. Their fabrication and installation are straightforward, thus contributing to their widespread adoption in the creation of mezzanine floors. Not only can they endure substantial loads, but they also provide a solid foundation for diverse applications, such as storage, offices, or supplementary workspaces. Furthermore, steel angles can be tailored to meet specific design prerequisites, showcasing their versatility as a prime option for mezzanine floor construction.

- Q: What are the different shapes available for steel angles?

- Steel angles come in various shapes, each serving a specific purpose in construction and structural applications. The most common shapes include the following: 1. Equal angles: These angles have legs of equal length and are formed by bending a single piece of steel. They find common use in general structural applications, such as supporting beams and columns. 2. Unequal angles: As the name suggests, these angles have legs of unequal length. They are often employed when one leg needs to be longer or shorter than the other. In construction, they provide additional strength and support in various applications. 3. L-shaped angles: These angles have one leg longer than the other, creating an L-shape. They are frequently used to reinforce corners and edges of structures, offering extra strength and support. 4. T-shaped angles: These angles have a longer leg that extends perpendicular to a shorter leg, forming a T-shape. They are commonly utilized as lintels or beams to support loads above openings like doors and windows. 5. C-shaped angles: These angles have one side curved inward, resulting in a C-shape. They are often employed in situations where the angle needs to fit around a curved or rounded surface, providing structural support and reinforcement. In summary, the availability of various steel angle shapes enables a wide range of applications in construction and structural engineering. They offer strength, support, and versatility in numerous projects.

Send your message to us

Unequal Steel Angle Hot Selling Various High Quality, Angle Steel, Angle Bars

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords