Unequal Angle Bars Hot sales&Free Sample Stainless Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 24000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | stainless steel unequal angle bars standard seaworthy packing(plastic&wooden) or according to the customer's requests |

| Delivery Detail: | stainless steel unequal angle bars delivey time is 15-25 days |

Specifications

stainless steel unequal angle bars

1.Plentiful storage and short delivery time

2.direct factory sales

3.Reasonable price

stainless steel unequal angle bar

Product Description

basic information

Standard | AISI,ASTM,DIN,GB,JIS |

Material | 201,202,301,304,304L,316,316L,321,410,420,430etc |

Surface | bright , polished , sand blasting ,Cold drawn , hot rolled, etc |

Diameter | 2.5#,3#,4#,5#,6#,7#,7.5#,8#,10# |

Length | 6mter or as your requirement |

Packing | seaworthy packing(plastic & wooden) or according to the customer's requests |

MOQ | 0.5TON |

Delivery time | 15-25 days, as quanlity |

Application | These products are widely used in all kinds of architecture and engineering structure, such as the beam, Bridges, transmission tower, hoisting, ship industrial furnace, container frame and warehouse and Other fields. |

Contacts | If you are interested in our product, please feel free to contact us. Welcome your requires and hope we can establish friendly and long cooperative relations |

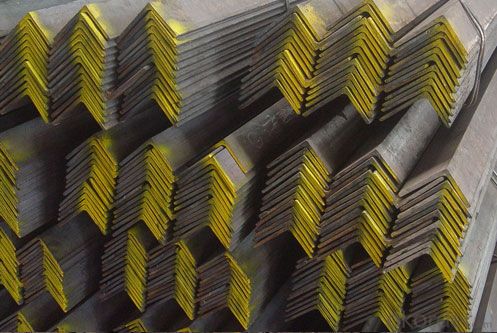

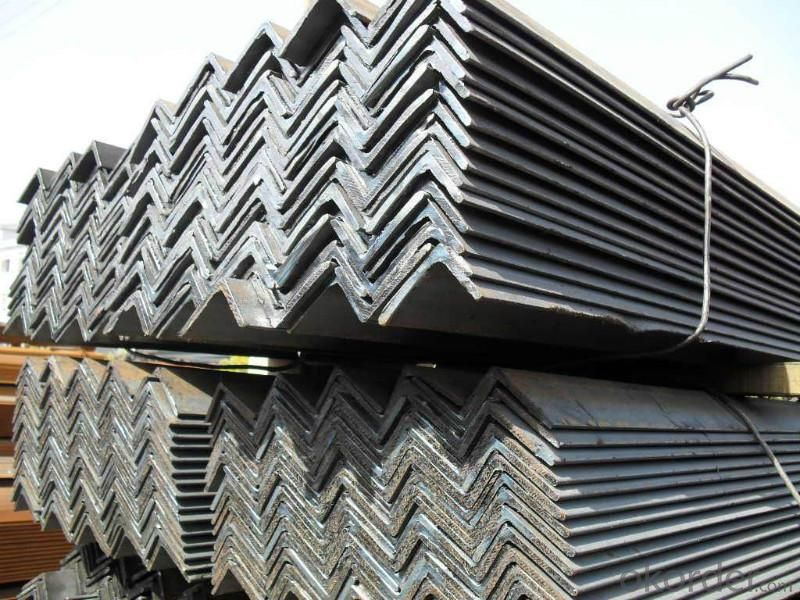

product picture

bright surface

why choose us?

1.In each manufacturing process,we arrange a technician in charge of inspection to make sure the final product completely qualified.

2.We take more machanized operations to decrease human labor cost.

3.We have an experienced term available to serve you,and supply you all you want.

4.In case of any problems occurs to our products you receive,we will redeliver them to you,or refund your payment,or solve it as the method we negotiate.

- Q: Can steel angles be used for manufacturing balcony structures?

- Indeed, balcony structures can be manufactured using steel angles. The utilization of steel angles in construction is widespread owing to their robustness and endurance. They offer structural reinforcement and steadiness, rendering them appropriate for balcony structures. Balcony construction frequently incorporates steel angles as supporting beams or framing elements, establishing a sturdy foundation for the flooring and railing. Moreover, steel angles can be effortlessly fabricated and tailored to conform to precise design specifications, making them a versatile option for manufacturing balconies.

- Q: Are steel angles suitable for constructing bridges?

- Yes, steel angles are suitable for constructing bridges. Steel angles offer excellent strength, durability, and versatility, making them a popular choice in bridge construction. They can be used to provide structural support, enhance stability, and distribute load effectively, ensuring the bridge's overall integrity and safety.

- Q: Can steel angles be used for transmission towers?

- Yes, steel angles can be used for transmission towers. Steel angles are commonly used in the construction industry for various structural applications, including transmission towers. They provide excellent strength and stability, making them suitable for supporting heavy loads and withstanding the rigors of outdoor environments. Steel angles can be easily fabricated, welded, and bolted together to form the required shapes and configurations for transmission towers. Additionally, they offer good corrosion resistance, which is crucial for structures exposed to weather conditions. Overall, steel angles are a popular and reliable choice for transmission tower construction.

- Q: Are steel angles suitable for earthquake-resistant construction?

- Yes, steel angles are suitable for earthquake-resistant construction. Steel angles have high strength and stiffness, which enables them to withstand the lateral forces and dynamic loads generated during an earthquake. They can be used in various structural elements, such as moment-resisting frames and bracing systems, to provide stability and resistance against seismic forces. Additionally, steel angles can be easily fabricated and installed, making them a popular choice in earthquake-resistant construction.

- Q: Are steel angles available in non-standard dimensions?

- Yes, steel angles are available in non-standard dimensions. While standard steel angles are typically produced in specific sizes, such as 2x2 inches or 3x3 inches, there are manufacturers and suppliers who can produce steel angles in custom sizes to meet specific project requirements. These non-standard dimensions could include different leg lengths, thicknesses, or overall dimensions that are not commonly found in standard steel angles. Custom steel angles can be fabricated through processes such as cutting, bending, and welding to achieve the desired dimensions. However, it is important to note that non-standard dimensions may require additional time and cost for production compared to readily available standard sizes.

- Q: Can steel angles be fire-resistant?

- Indeed, steel angles possess fire-resistant qualities. Being a material, steel inherently possesses fire resistance due to its high melting point and low thermal conductivity. When faced with elevated temperatures, steel angles can retain their structural integrity and withstand deformation for a significant duration. Furthermore, fire resistance in steel angles can be augmented through diverse approaches, such as the utilization of fire-resistant coatings or the integration of fire-resistant materials in their design. These measures serve to heighten the fire resistance capacity of steel angles, rendering them appropriate for scenarios where fire protection is imperative, such as the establishment of fire-resistant walls, ceilings, and structural systems in construction projects.

- Q: Can steel angles be used for conveyor systems?

- Yes, steel angles can be used for conveyor systems. Steel angles are often used as structural supports in conveyor systems due to their strength and durability. They can be used to create frames, supports, and guides for the conveyor belts, ensuring stability and proper functioning of the system.

- Q: How do you determine the required number of steel angles for a project?

- Determining the necessary quantity of steel angles for a project involves taking into account several factors. First and foremost, it is crucial to comprehend the project's design and specifications. This encompasses the structural prerequisites, load-bearing capacities, and any specific angles or dimensions that must be incorporated. Subsequently, the dimensions of the steel angles need to be ascertained based on the intended utilization and structural prerequisites. This entails considering the suitable length, width, and thickness of the angles for the project. Once the dimensions are established, the subsequent step involves calculating the requisite number of angles. This can be accomplished by meticulously measuring and estimating the lengths of the steel angles required in each area of the project. It is important to take into account any potential waste or additional cuts that might be necessary during the installation process. Furthermore, it is advisable to seek advice from structural engineers or professionals well-versed in steel fabrication to ensure precise calculations and to confirm that the chosen steel angles fulfill the necessary safety standards and building codes. Ultimately, determining the necessary quantity of steel angles for a project necessitates a combination of meticulous planning, accurate measurements, and professional expertise to guarantee that the project is structurally sound and meets all the necessary requirements.

- Q: Can steel angles be used in the construction of storage tanks?

- Yes, steel angles can be used in the construction of storage tanks. Steel angles provide structural support and enhance the overall integrity of the tank. They are commonly used for the construction of tank roofs, tank bottoms, and tank supports. Their strength and durability make them suitable for withstanding the pressure and weight of the tank's contents.

- Q: What are the different types of steel coatings available for angles?

- Angles can be coated with various types of steel coatings, each with its own unique characteristics and benefits. Some commonly used coatings include: 1. Galvanized coating: This is a popular choice for steel angles as it involves applying a layer of zinc to the surface, providing excellent corrosion resistance. Galvanized angles are commonly used in outdoor settings or in places with high moisture levels. 2. Powder coating: This dry finishing process involves applying a fine powder to the steel angles, creating a smooth and durable finish. Powder coating is resistant to scratches, chipping, and fading, making it ideal for decorative or architectural applications. 3. Epoxy coating: These thermosetting polymer coatings offer exceptional resistance to chemicals, corrosion, and abrasion. They are commonly used in harsh industrial environments like chemical plants or wastewater treatment facilities. 4. Paint coating: Paint coatings are a cost-effective option for steel angles and can be customized in terms of color and finish. While they provide some level of corrosion protection, they may not be as durable as other coatings and are best suited for indoor or low-corrosion applications. 5. Organic coating: Organic coatings like polyurethane or polyester are used to provide both decorative and protective layers to steel angles. They offer excellent resistance to UV radiation, weathering, and fading, making them suitable for outdoor projects in the fields of architecture, construction, or infrastructure. When selecting a steel coating for angles, it's crucial to consider the specific requirements of your application. Environmental conditions, aesthetic preferences, and durability needs should all be taken into account to ensure the proper selection of the coating that best suits your project.

Send your message to us

Unequal Angle Bars Hot sales&Free Sample Stainless Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 24000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords