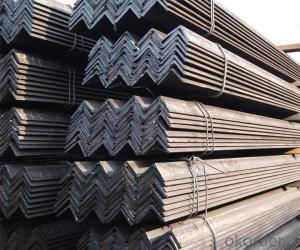

Unequal Leg Angle Steel SS400 Hot-Rolled Mild Steel for Shipbuilding

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 24 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Unequal Leg Angle Steel SS400 Hot-Rolled Mild Steel for Shipbuilding at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Unequal Leg Angle Steel SS400 Hot-Rolled Mild Steel for Shipbuilding are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Unequal Leg Angle Steel SS400 Hot-Rolled Mild Steel for Shipbuilding are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Size Leg Length×Leg Length×thickness (mm) | GB Weight (kg/m) | Available Length | Size Leg Length×Leg Length×thickness (mm) | GB Weight (kg/m) | Available Length |

50×32×3 | 1.908 | 6-12m | 100×80×10 | 13.476 | 6-12m |

50×32×4 | 2.494 | 6-12m | 110×70×8 | 10.946 | 6-12m |

56×36×3 | 2.153 | 6-12m | 110×70×10 | 13.476 | 6-12m |

56×36×4 | 2.818 | 6-12m | 125×80×8 | 12.551 | 6-12m |

56×36×5 | 3.466 | 6-12m | 125×80×10 | 15.474 | 6-12m |

63×40×5 | 3.920 | 6-12m | 125×80×12 | 18.330 | 6-12m |

63×40×6 | 4.638 | 6-12m | 140×90×8 | 14.160 | 6-12m |

75×50×5 | 4.808 | 6-12m | 140×90×10 | 17.475 | 6-12m |

75×50×6 | 5.699 | 6-12m | 140×90×12 | 20.724 | 6-12m |

75×50×8 | 7.431 | 6-12m | 160×100×10 | 19.872 | 6-12m |

90×56×6 | 6.717 | 6-12m | 160×100×12 | 23.592 | 6-12m |

90×56×7 | 7.756 | 6-12m | 180×110×10 | 22.273 | 6-12m |

90×56×8 | 8.779 | 6-12m | 180×110×12 | 26.464 | 6-12m |

100×63×6 | 7.550 | 6-12m | 200×125×12 | 29.761 | 6-12m |

100×63×7 | 8.722 | 6-12m | 200×125×14 | 34.436 | 6-12m |

100×63×8 | 9.878 | 6-12m | 200×125×16 | 39.045 | 6-12m |

100×63×10 | 12.142 | 6-12m | 200×125×18 | 43.588 | 6-12m |

100×80×8 | 10.946 | 6-12m |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: What are the welding techniques used for steel angles?

- Some common welding techniques used for steel angles include shielded metal arc welding (SMAW), gas metal arc welding (GMAW), and flux-cored arc welding (FCAW). These techniques are effective in joining steel angles due to their ability to provide strong and durable welds.

- Q: How do steel angles perform under seismic loads?

- Steel angles are commonly used in construction to provide structural support and reinforcement. When subjected to seismic loads, steel angles have been found to perform exceptionally well due to their inherent properties and design flexibility. One key advantage of steel angles is their high strength-to-weight ratio. This allows them to withstand the intense forces and movements generated during an earthquake without significant deformation or failure. The compact shape of the angle also helps distribute the load more efficiently, minimizing stress concentrations and potential weak points. Moreover, steel angles can be easily connected to other structural elements, providing a robust and reliable connection system. This is particularly important in seismic design, where the ability to transfer forces and accommodate movements is essential. To further enhance their performance under seismic loads, steel angles can be designed with specific features. For instance, the addition of stiffeners or bracing elements can increase their resistance to lateral forces, reducing the risk of buckling or collapse. Additionally, the use of thicker and stronger steel grades can improve their overall capacity to absorb and dissipate seismic energy. Various seismic design codes and standards provide guidelines and requirements for the use of steel angles in seismic-resistant structures. These codes consider factors such as the maximum allowable stress levels, detailing requirements for connections, and the overall structural behavior under seismic actions. In conclusion, steel angles perform admirably under seismic loads due to their high strength-to-weight ratio, efficient load distribution, and flexibility in design. When properly designed and implemented, steel angles can effectively resist the forces and movements generated during an earthquake, ensuring the structural integrity and safety of the building.

- Q: How do you connect steel angles together?

- Steel angles can be connected together by various methods such as welding, bolting, or using steel angle brackets.

- Q: What are the load-bearing capacities of different sizes and types of steel angles?

- The load-bearing capacities of different sizes and types of steel angles vary depending on factors such as the material grade, dimensions, and specific design requirements. It is essential to consult engineering tables or design codes, as they provide detailed information on load-bearing capacities for different steel angles.

- Q: How do steel angles provide structural support?

- Structural support is provided by steel angles, which evenly and efficiently distribute weight and load in a structure. These L-shaped steel beams are commonly used in construction. The stability and strength of the angle's two legs enable it to resist bending and twisting forces. Steel angles are frequently combined with other structural components like beams, columns, and trusses to establish a stable framework. They can be connected to these components through bolting, welding, or other methods to offer additional support and reinforcement. Due to their versatility, steel angles can be utilized in various applications, including building frames, supports, bracing, and structural reinforcement. The incorporation of steel angles in a structure helps evenly distribute weight and load across different components, reducing the risk of structural failure. They effectively resist compressive, tensile, and bending forces, providing stability and preventing deformation under heavy loads or external forces like wind or earthquakes. Furthermore, steel angles serve to create secure connections and joints between different parts of a structure, ensuring their firm fastening. This enhances overall stability and integrity, making the structure more resistant to movement, vibrations, and other external factors that could compromise safety. In summary, steel angles play a vital role in providing structural support. They distribute weight, resist bending and twisting forces, enhance stability, and reinforce connections between different structural components. Their strength, versatility, and reliability make them a popular choice in construction projects where structural integrity and stability are paramount.

- Q: What are the different types of connections used for steel angles in educational institutions?

- In educational institutions, there are several types of connections used for steel angles. These connections serve to join steel angles together in various applications and structural configurations. Some of the common types of connections used are: 1. Welded Connections: Welding is a widely used method to connect steel angles in educational institutions. It involves melting and fusing the steel angles together using heat, creating a strong and durable connection. Welded connections are often used in structural applications where high strength and rigidity are required. 2. Bolted Connections: Bolted connections involve using bolts, nuts, and washers to secure steel angles together. This type of connection allows for easy disassembly and reassembly, making it suitable for applications where flexibility and adjustability are desired. Bolted connections are commonly used in non-structural applications like furniture, handrails, and brackets. 3. Riveted Connections: Riveting is an older method of connection, where steel angles are joined using rivets. Rivets are inserted through pre-drilled holes in the angles and then hammered or compressed to secure the connection. Although not as commonly used today, riveted connections can still be found in some older structures within educational institutions. 4. Clip Connections: Clip connections involve using specially designed clips or brackets to connect steel angles together. These clips are typically bolted or welded to the angles, providing a quick and efficient method of connection. Clip connections are often used in applications where easy installation and maintenance are important, such as suspended ceilings or modular structures. 5. Gusset Plate Connections: Gusset plate connections involve using additional steel plates (gusset plates) to connect steel angles. The gusset plates are typically welded or bolted to the angles, providing additional strength and stability to the connection. This type of connection is commonly used in heavy-duty structural applications, such as trusses or frames, within educational institutions. Overall, the selection of the type of connection for steel angles in educational institutions depends on factors such as the load requirements, structural design, ease of installation, and maintenance considerations. It is essential to consult with structural engineers and follow applicable building codes and regulations to ensure safe and appropriate connections are used.

- Q: Are steel angles suitable for supporting heavy machinery?

- Indeed, steel angles possess the necessary attributes to effectively support heavy machinery. Boasting strength, durability, and an elevated load-bearing capacity, these angles emerge as a prime selection for bolstering heavy machinery. Their prevalence in both industrial settings and construction ventures is a testament to their ability to furnish structural support. By either employing bolts or welding techniques, one can seamlessly amalgamate these angles, yielding a robust framework capable of withstanding the weight and vibrations engendered by heavy machinery. Moreover, the versatility of steel angles permits customization, facilitating the development of resilient and dependable support structures tailored to meet specific requirements posed by heavy machinery.

- Q: What are the different types of steel angles used in modular furniture?

- There are several different types of steel angles used in modular furniture, including equal angles, unequal angles, L-shaped angles, and slotted angles. These angles are used to provide structural support, reinforcement, and stability to the furniture pieces.

- Q: How do you join steel angles together?

- One common method to join steel angles together is by using welding techniques. This involves heating the joint area to a high temperature and fusing the angles together using a welding electrode or filler material. Welding creates a strong and durable bond between the steel angles, ensuring structural integrity.

- Q: Can steel angles be used in electrical installations?

- Yes, steel angles can be used in electrical installations. They are often used as structural supports or brackets for mounting electrical equipment such as junction boxes, conduit systems, or cable trays. Steel angles provide strength and stability to secure and organize electrical components effectively.

Send your message to us

Unequal Leg Angle Steel SS400 Hot-Rolled Mild Steel for Shipbuilding

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 24 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords