Hot Rolled Steel Unequal Angle Steel Good Price SS400 Competitive Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled Steel Unequal Angle Steel Good Price SS400 Competitive Price at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Steel Unequal Angle Steel Good Price SS400 Competitive Price are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Hot Rolled Steel Unequal Angle Steel Good Price SS400 Competitive Price are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Specifications of Angle Steel

1. Invoicing on theoretical weight or actual weight as customer request.

2. Length: 6m, 9m, 12m.

3. Sizes:

Size(mm) | Mass(Kg/m) | Size(mm) | Mass(Kg/m) |

50*50*4 | 3.059 | 63*63*5 | 4.822 |

50*50*5 | 3.77 | 63*63*6 | 5.721 |

50*50*6 | 4.465 | | |

Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C.

Packaging & Delivery of Hot Rolled Steel Unequal Angle Steel Good Price SS400 Competitive Price

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

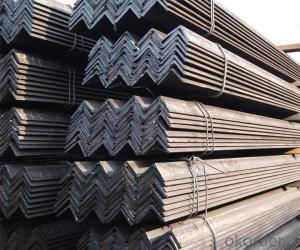

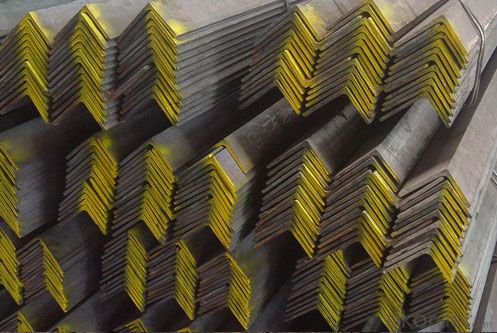

Images:

- Q: What are the different connections used with steel angles?

- There are several different connections that can be used with steel angles, including bolted connections, welded connections, and clip connections. Bolted connections involve using bolts and nuts to connect the angles to other structural members. Welded connections involve fusing the angles to the other members using a welding process. Clip connections involve using clips or brackets to secure the angles to the other members. The choice of connection depends on factors such as the load requirements, design specifications, and fabrication capabilities.

- Q: Can steel angles be used in the construction of sports stadiums?

- Yes, steel angles can be used in the construction of sports stadiums. Steel angles are commonly used as structural components in various construction applications, including sports stadiums. They provide strength, support, and stability to the overall structure, making them a suitable choice for constructing large-scale venues like sports stadiums.

- Q: What are the different methods of surface finishing for steel angles?

- Some of the different methods of surface finishing for steel angles include painting, galvanizing, powder coating, and abrasive blasting.

- Q: Can steel angles be used for decorative purposes?

- Yes, steel angles can definitely be used for decorative purposes. Steel angles are versatile and can be shaped and formed into various designs and patterns, making them a popular choice for adding a decorative touch to interior and exterior spaces. They can be used to create decorative accents such as trim, frames, and brackets. Additionally, steel angles can be easily painted or powder-coated in different colors to match any desired aesthetic. The durability and strength of steel angles also ensure that they will withstand the test of time, making them a practical and attractive option for decorative applications.

- Q: What are the different methods of protecting steel angles against corrosion?

- Various methods are available to safeguard steel angles against corrosion, with the choice contingent upon factors such as the surrounding environment, budgetary constraints, and desired lifespan of the steel angles. Below are some commonly employed techniques: 1. Protective Coatings: The application of protective coatings stands as one of the most efficient approaches to prevent corrosion. Coatings like paint, epoxy, or polyurethane establish a barrier between the steel surface and corrosive elements. To ensure sufficient protection, multiple layers of these coatings should be applied. Regular inspections and touch-ups may be necessary to maintain the integrity of the coating. 2. Galvanization: Galvanizing steel angles involves coating them with a layer of zinc, creating a sacrificial barrier that corrodes before the steel does. This method proves highly effective in corrosion prevention, especially in harsh environments. However, it may not be suitable for aesthetic purposes as the zinc layer can alter the appearance of the steel. 3. Stainless Steel: Another means of corrosion protection is through the use of stainless steel angles. Stainless steel contains a substantial amount of chromium, which forms a passive layer on the surface, shielding it from corrosion. Stainless steel is particularly advantageous in corrosive settings like marine or chemical industries. 4. Powder Coating: The powder coating technique comprises the application of dry powder onto the steel angles, followed by heating to create a protective layer. This method offers exceptional corrosion resistance and can provide an aesthetically pleasing finish. Powder coating is commonly employed in architectural applications where aesthetics hold importance. 5. Cathodic Protection: Cathodic protection relies on an electrochemical process to thwart corrosion by designating the steel angle as the cathode in a galvanic cell. This is accomplished by connecting the steel to a sacrificial anode, often made of a more reactive metal such as zinc or magnesium. The anode corrodes in place of the steel angle, providing protection. 6. Regular Maintenance: Irrespective of the protective method employed, regular inspection and maintenance play a crucial role. This entails cleaning the steel angles, eliminating any debris or corrosive substances, and promptly rectifying any damaged or scratched coatings. Regular maintenance aids in identifying and addressing early signs of corrosion, thereby ensuring the prolonged lifespan of the steel angles. To determine the most suitable method for protecting steel angles based on specific requirements and conditions, it is imperative to consult corrosion experts or engineers.

- Q: Can steel angles be used for framing windows and doors?

- Absolutely! Framing windows and doors with steel angles is a fantastic option. In construction, these angles are widely favored due to their exceptional strength and durability. They establish a robust structure, guaranteeing ample support and stability for windows and doors. Moreover, steel angles possess remarkable resistance against warping, shrinking, and rotting, making them the perfect choice for any framing requirement.

- Q: Are steel angles vulnerable to rusting?

- Certainly, rusting can affect steel angles. Steel, being predominantly composed of iron, is greatly prone to rusting upon exposure to moisture and oxygen. In the absence of a reliable corrosion-resistant coating or paint, it is highly likely for the steel angles to gradually accumulate rust. This rust accumulation can diminish the angles' structural durability, ultimately undermining their effectiveness. In order to minimize the risk of rusting and extend the lifespan of steel angles, it is important to regularly maintain them and employ suitable rust prevention measures such as painting or galvanizing.

- Q: How do you calculate the deflection of a steel angle?

- To determine the deflection of a steel angle, one must take into account various factors and utilize the correct formulas. Typically, the deflection of a beam or angle is calculated using the Euler-Bernoulli beam theory, which assumes small deflections and a slender beam. Initially, the moment of inertia (I) of the steel angle needs to be calculated. This can be done by considering the dimensions and properties of the angle section. The moment of inertia reflects the angle's resistance to bending. Subsequently, the applied load or force (F) acting on the steel angle should be determined. This could be a concentrated load, distributed load, or a combination of both. The load induces a bending moment (M) on the angle. Once the moment of inertia and the bending moment are established, the formula for deflection in a simply supported beam can be employed: To calculate the deflection at the midpoint of the steel angle (δ), use the following equation: δ = (5 * M * L^4) / (384 * E * I) In this equation: - δ represents the deflection at the midpoint of the steel angle - M denotes the bending moment applied to the angle - L signifies the length of the angle - E represents the modulus of elasticity of the steel material - I indicates the moment of inertia of the angle section By substituting the appropriate values into the formula, one can compute the deflection. It is crucial to ensure that the units are consistent and compatible during the calculation process. However, it is important to note that this calculation assumes linear behavior and disregards factors like shear deformation and lateral torsional buckling. For more precise results, additional factors should be taken into account or engineering resources, such as design codes or software, should be consulted for a more accurate deflection calculation.

- Q: Can steel angles support heavy machinery or equipment?

- Yes, steel angles can support heavy machinery or equipment. Steel angles are commonly used in structural applications due to their high strength and durability. They provide excellent support and stability, making them suitable for handling heavy loads.

- Q: Can steel angles be used for architectural detailing or ornamentation?

- Yes, steel angles can be used for architectural detailing or ornamentation. They are commonly used to add structural support, create unique design elements, and enhance the aesthetic appeal of buildings. Their versatility, strength, and durability make them suitable for various architectural applications.

Send your message to us

Hot Rolled Steel Unequal Angle Steel Good Price SS400 Competitive Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords