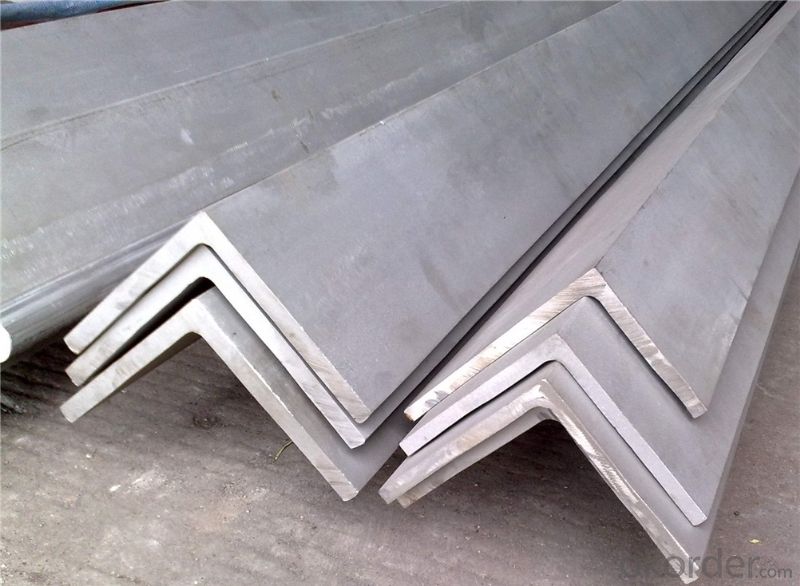

S400 Hot rolled stainless steel angle for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100000 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

OKorder is offering S400 hot rolled stainless steel angle for construction at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot rolled stainless steel angle are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's steel angle are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Specifications of Angle Steel

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

3. Sizes

Sizes: 25mm-250mm | ||

a*t | ||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 |

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 |

36*3.0-5.0 | 80*5.0-10 | 150*10-20 |

38*2.3-6.0 | 90*7.0-10 | 160*10-16 |

40*3.0-5.0 | 100*6.0-12 | 175*12-15 |

45*4.0-6.0 | 110*8.0-10 | 180*12-18 |

50*4.0-6.0 | 120*6.0-15 | 200*14-25 |

60*4.0-8.0 | 125*8.0-14 | 250*25 |

5. Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

Packaging & Delivery of Angle Steel

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

Production flow of Angle Steel

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

- Q: How do you reinforce a steel angle?

- One way to reinforce a steel angle is by adding additional structural elements such as steel plates or gussets. These can be welded or bolted onto the angle to increase its strength and load-bearing capacity. Additionally, using thicker and higher-grade steel angles can also provide increased reinforcement.

- Q: Can steel angles be used for mezzanines or catwalks?

- Yes, steel angles can be used for mezzanines or catwalks. Steel angles are often used as structural supports in construction projects due to their strength and versatility. They can provide the necessary stability and load-bearing capacity required for mezzanines and catwalks, making them a suitable choice for such applications.

- Q: How do steel angles perform in extreme temperatures?

- Steel angles perform well in extreme temperatures due to their high strength and excellent heat resistance. They retain their structural integrity and do not easily deform or become brittle under extreme heat or cold conditions. This makes steel angles a reliable choice for various applications in industries such as construction, manufacturing, and engineering, where exposure to extreme temperatures is common.

- Q: Can steel angles be used in mezzanine or raised platform construction?

- Yes, steel angles can be used in mezzanine or raised platform construction. Steel angles provide structural support and stability, making them a suitable choice for such applications.

- Q: Are steel angles resistant to chemical corrosion?

- Yes, steel angles are resistant to chemical corrosion due to the protective oxide layer that forms on their surface, which helps prevent chemical reactions and corrosion.

- Q: 6# specification for angle iron

- Angle: the angle called angle, the steel strip is perpendicular to each other on both sides into the corner. The angle iron has equal angles and unequal angles. The two sides of an equal angle steel are equal in width. The specifications are expressed in millimeters of edge width * edge width * edge thickness. Such as "/ 30 x 30 x 3", that is 30 mm width equal angle, edge thickness of 3 mm. Also available models that model is the number of centimeters wide, such as angle 3#. The model does not mean the size of the different edges and sizes of the same model. Therefore, the width, the edge and the thickness of the angle iron should be filled out in the contract and other documents, so as not to be indicated by the model alone. Standard Specification for hot-rolled equal angle iron is 2#-20#.

- Q: Can steel angles be used for manufacturing decorative brackets?

- Yes, steel angles can be used for manufacturing decorative brackets. The angles can be cut and shaped to create various designs, making them suitable for decorative purposes while also providing the necessary strength and durability.

- Q: How do you calculate the bending capacity of a steel angle?

- In order to determine the bending capacity of a steel angle, several factors must be considered. The initial step involves calculating the moment of inertia (I) of the angle section, which measures its resistance to bending. The moment of inertia relies on the angle's shape and dimensions, and can be found in the manufacturer's specifications or through calculations. Once the moment of inertia has been obtained, the section modulus (Z) can be calculated as another indicator of the section's ability to resist bending. The section modulus is found by dividing the moment of inertia by the distance from the centroid of the section to the extreme fiber. Subsequently, it is necessary to establish the maximum allowable bending stress (σ) for the steel angle. This value is typically provided by the manufacturer or can be determined based on the desired safety factor and the type of steel being used. Lastly, the bending capacity (M) of the steel angle can be calculated by utilizing the formula M = σ * Z. This calculation provides the maximum moment that the angle can endure without experiencing excessive bending stress. It is important to note that these calculations assume the angle's behavior is elastic and do not account for additional factors such as local buckling, residual stresses, or combined loading. Therefore, it is advisable to consult relevant design codes or guidelines for a more comprehensive analysis to ensure the safety and reliability of the steel angle in a specific application.

- Q: What are the different types of steel angles used in agricultural applications?

- There are several different types of steel angles commonly used in agricultural applications. 1. Equal Angle: This type of steel angle has equal sides and is often used for structural support in agricultural buildings, such as barns and sheds. It provides stability and strength, making it suitable for load-bearing applications. 2. Unequal Angle: As the name suggests, this steel angle has unequal sides, with one side longer than the other. It is commonly used in agricultural machinery, such as tractor attachments and implements. The unequal sides allow for better positioning and attachment of various components. 3. Lipped Angle: Lipped angles are similar to equal angles but have an additional lip or flange on one side. This lip provides added support and rigidity, making it ideal for agricultural applications that require extra strength, such as fencing and gate posts. 4. Slotted Angle: Slotted angles are versatile and can be adjusted to different angles as needed. They are commonly used in agricultural shelving systems, allowing farmers to create custom storage solutions for tools, equipment, and supplies. The slots in the angles provide flexibility for adjusting shelf heights. 5. Rolled Steel Angle: Rolled steel angles are produced by rolling steel into angle-shaped sections. They are commonly used in agricultural construction for bracing, supporting beams, and framing. Rolled steel angles offer high strength and durability, making them suitable for demanding agricultural environments. Each type of steel angle has its unique characteristics and advantages, and the choice depends on the specific agricultural application and the level of strength and support required. It is important to consider factors such as load-bearing capacity, durability, and resistance to corrosion when selecting the appropriate steel angle for agricultural use.

- Q: What are the disadvantages of using steel angles?

- Using steel angles in various applications comes with several drawbacks. One major disadvantage is their vulnerability to corrosion. These angles are typically made from carbon steel, which tends to rust when exposed to moisture and harsh environmental conditions. As a result, their structural integrity weakens over time, reducing their durability. Another drawback is their weight and bulkiness. Steel angles are often heavy and cumbersome, making them challenging to handle and transport. This can drive up project costs, as special equipment or additional labor may be necessary for installation. Steel angles also have limited flexibility and versatility in terms of design. They are usually only available in standard sizes and shapes, which restricts their use in certain applications that require customized or intricate designs. This lack of flexibility can lead to additional expenses for fabrication or the need for alternative materials. Moreover, steel angles tend to be more expensive compared to materials like aluminum or wood. This makes them less cost-effective in certain projects, especially when alternative materials can meet the structural requirements at a lower cost. Lastly, steel angles conduct heat and electricity, which may not be desirable in certain applications. This poses safety risks in environments that are sensitive to heat or electricity, necessitating additional insulation or protective measures. In conclusion, although steel angles offer advantages like high strength and durability, their disadvantages include susceptibility to corrosion, weight and bulkiness, limited design flexibility, higher cost, and heat and electricity conductivity. These factors should be carefully evaluated when deciding whether to use steel angles in a specific project.

Send your message to us

S400 Hot rolled stainless steel angle for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100000 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords