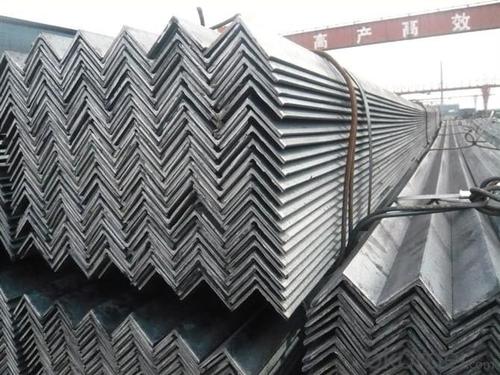

Equal Angle Steel Hot Rolled SS400-SS540 Series

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Equal Angle Steel Hot Rolled SS400-SS540 Series at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Equal Angle Steel Hot Rolled SS400-SS540 Series are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Equal Angle Steel Hot Rolled SS400-SS540 Series are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Equal Angle Steel

1) Size:20-250mm,

Thickness:3-16mm,length:6-12m

2) Material: Q195/235/345, SS400,ST37-2,ASTM A36

Equal angle steel

1.Standard: GB, ASTM, JIS, DIN.ect

2.Grade: Q195,Q235,Q345,A36,SS400, ST37-2.ect

3.Specification: 20*20--200*200mm. Thickness: 3-24mm.Length: common length 5.8m, 6m,11.8m,12m

4. Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

5. Packing: with bundles and load in 20 feet/40 feet container, or by bulk cargo( if with large quantity), also we could do as customer's request.

If you have any other demand, pls contact me freely. Hope our products will work for your business.

Reference sizes, pls check it as below,

Size | Theoretical weight | Size | Theoretical weight | Size | Theoretical weight |

(mm) | (kg/m) | (mm) | (kg/m) | (mm) | (kg/m) |

25*3 | 1.124 | 70*6 | 6.406 | 100*16 | 23.257 |

25*4 | 1.459 | 70*7 | 7.398 | 110*8 | 13.532 |

30*3 | 1.373 | 70*8 | 8.373 | 110*10 | 16.69 |

30*4 | 1.786 | 75*5 | 5.818 | 110*12 | 19.782 |

40*3 | 1.852 | 75*6 | 6.905 | 110*14 | 22.809 |

40*4 | 2.422 | 75*7 | 7.976 | 125*8 | 15.504 |

40*5 | 2.967 | 75*8 | 9.03 | 125*10 | 19.133 |

50*3 | 2.332 | 75*10 | 11.089 | 125*12 | 22.696 |

50*4 | 3.059 | 80*6 | 7.736 | 125*14 | 26.193 |

50*5 | 3.77 | 80*8 | 9.658 | 140*10 | 21.488 |

50*6 | 4.465 | 80*10 | 11.874 | 140*12 | 25.522 |

60*5 | 4.57 | 90*8 | 10.946 | 140*14 | 29.49 |

60*6 | 5.42 | 90*10 | 13.476 | 160*12 | 29.391 |

63*4 | 3.907 | 90*12 | 15.94 | 160*14 | 33.987 |

63*5 | 4.822 | 100*8 | 12.276 | 160*16 | 38.518 |

63*6 | 5.721 | 100*10 | 15.12 | 160*18 | 48.63 |

63*8 | 7.469 | 100*12 | 17.898 | 180*18 | 48.634 |

70*5 | 5.397 | 100*14 | 20.611 | 200*24 | 71.168 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q: What is the maximum load capacity of a steel angle?

- The maximum load capacity of a steel angle is determined by various factors including its dimensions, thickness, grade, and quality. Steel angles are generally built to withstand significant loads due to their structural characteristics. However, it is essential to refer to engineering specifications and relevant building codes to determine the specific maximum load capacity of a steel angle in a particular application. The load capacity is usually calculated by considering the angle's cross-sectional area, the material's yield strength, and the applied load factors. Furthermore, factors such as the angle's length, support conditions, and the presence of any additional reinforcement or bracing can also affect the maximum load capacity. It is vital to ensure that the steel angle is chosen, designed, and installed correctly to safely support the intended loads and comply with the necessary structural standards.

- Q: How do you protect steel angles from chemical exposure?

- To protect steel angles from chemical exposure, there are several measures that can be taken: 1. Coatings: Applying protective coatings such as epoxy, polyurethane, or powder coatings can create a barrier between the steel surface and the chemicals. These coatings are specifically designed to resist chemical attacks and provide long-term protection. 2. Galvanization: Galvanizing steel angles involves applying a layer of zinc to the surface, forming a protective barrier. This process not only protects against chemical exposure but also provides excellent corrosion resistance. 3. Chemical-resistant paint: Using chemical-resistant paint, specifically formulated to withstand exposure to certain chemicals, can provide an added layer of protection. These paints are designed to resist the corrosive effects of various chemicals and prevent damage to the steel angles. 4. Plastic or rubber linings: In some cases, steel angles can be lined with plastic or rubber materials to protect them from chemical exposure. These linings act as a barrier, preventing direct contact between the steel and chemicals. 5. Proper ventilation: Ensuring proper ventilation in the area where steel angles are exposed to chemicals is crucial. Adequate ventilation helps to disperse and dilute the chemicals, reducing the overall exposure and minimizing the corrosive effects on the steel angles. 6. Regular inspection and maintenance: Regularly inspecting the steel angles for any signs of corrosion or damage caused by chemical exposure is vital. If any damage is detected, it should be repaired promptly to prevent further deterioration. It is important to note that the choice of protection method may vary depending on the type of chemicals involved, their concentration, and the specific environment in which the steel angles are exposed. Consulting with a professional or a corrosion specialist is recommended to determine the most suitable protection strategy for a particular application.

- Q: How do steel angles perform in terms of thermal conductivity?

- Steel angles have relatively low thermal conductivity compared to other materials. This means that they are not as efficient in conducting heat as materials such as aluminum or copper. However, steel angles still have moderate thermal conductivity, which allows them to dissipate heat to some extent. This property can be advantageous in certain applications where heat transfer needs to be controlled or balanced. Overall, while steel angles may not have the highest thermal conductivity, they still offer sufficient performance for many structural and construction purposes.

- Q: What are the different tolerances for steel angles?

- The different tolerances for steel angles depend on the specific manufacturing standards and specifications. Generally, the tolerances for steel angles are determined by the governing bodies or organizations that set industry standards, such as the American Society for Testing and Materials (ASTM) or the International Organization for Standardization (ISO). The tolerances for steel angles can vary based on factors such as the angle's dimensions, shape, and intended application. These tolerances ensure that the angles meet the required dimensional and geometric specifications, allowing them to be used effectively in various structural or engineering applications. Some common tolerances for steel angles include: 1. Dimensional Tolerances: These tolerances define the allowable variations in length, width, and thickness of the angle. For example, a 90-degree angle might have a tolerance of +/- 1/8 inch in its leg length or a maximum deviation of 2 degrees from the specified angle. 2. Straightness Tolerances: This tolerance measures the allowable deviation from a straight line along the length of the angle. It ensures that the angle does not have excessive bends or twists, which may affect its structural integrity. 3. Surface Finish Tolerances: These tolerances specify the acceptable variations in the surface finish of the angle, such as roughness or surface irregularities. They ensure that the angle meets the required aesthetic and functional standards. 4. Squareness Tolerances: Squareness tolerance measures the maximum allowable deviation from a perfect right angle for angles that are specified to be 90 degrees. It ensures that the angle maintains its intended shape and can be properly joined or connected to other components. 5. Weight Tolerances: These tolerances define the acceptable variations in the weight of the steel angle. They ensure that the angle meets the specified weight requirements, which may be crucial in applications where weight distribution plays a role. It is important to note that the specific tolerances for steel angles may vary depending on the region, industry, or project requirements. Therefore, it is essential to consult the relevant standards or specifications to determine the appropriate tolerances for a specific steel angle.

- Q: Are steel angles resistant to chemical corrosion?

- Steel angles have some resistance to chemical corrosion. Although steel is generally strong and durable, it can still corrode in the presence of certain chemicals and corrosive environments. However, steel angles are often treated or coated with protective materials like galvanization, which greatly improves their resistance to chemical corrosion. Galvanized steel angles have a zinc layer on their surface that acts as a barrier against corrosive substances. This coating helps prevent direct contact between the steel and chemicals, reducing the risk of corrosion. It's important to note, though, that the level of resistance may vary depending on the specific chemical, as well as the duration and intensity of exposure. To ensure long-term corrosion resistance, regular maintenance and inspection of steel angles are necessary.

- Q: How do steel angles contribute to the overall sustainability of a building?

- Steel angles contribute to the overall sustainability of a building in several ways. Firstly, they are often made from recycled steel, reducing the demand for raw materials and the energy required for manufacturing. Additionally, steel angles are durable and long-lasting, reducing the need for frequent replacements and minimizing waste. Their strength and versatility also allow for efficient structural designs, optimizing the use of materials and reducing the overall weight of the building. Lastly, steel angles can be easily recycled at the end of their life cycle, further reducing the environmental impact of the building.

- Q: What are the different types of steel angles connections?

- There are several different types of steel angle connections used in construction and engineering projects. Some of the most common types include: 1. Welded Connection: This is the most straightforward type of steel angle connection, where the angles are joined together using welding techniques. It provides a strong and rigid connection, but it requires skilled welders and can be time-consuming. 2. Bolted Connection: In this type of connection, the angles are connected by bolts, nuts, and washers. It allows for easier disassembly and modification, making it a popular choice for temporary structures or where future changes may be required. Bolted connections can be used with or without additional reinforcement, such as gussets or plates. 3. Riveted Connection: Riveting involves joining the angles using rivets, which are metal pins with a head on one end. Rivets are inserted into pre-drilled holes and then hammered to form a permanent connection. Although less common nowadays, riveted connections were widely used in older steel structures and bridges. 4. Clip Angle Connection: This type of connection involves using clip angles, which are small steel angles that are bolted or welded to the main angles. Clip angles provide additional support and reinforcement to the primary connection, enhancing its strength and stability. 5. Pinned Connection: Pinned connections allow for rotational movement between the angles, providing flexibility and allowing for load redistribution. They typically involve a pin or bolt passing through holes in the angles, allowing them to rotate freely. 6. Gusset Plate Connection: Gusset plates are flat steel plates that are used to connect and reinforce the angles. They are usually bolted or welded to the angles and provide additional strength and stability to the connection. The choice of steel angle connection depends on various factors such as the load-bearing requirements, structural design, ease of installation, and the need for future modifications. Each type has its advantages and disadvantages, and engineers select the most suitable connection type based on the specific project requirements.

- Q: Can steel angles be customized to specific dimensions?

- Absolutely, specific dimensions can indeed be applied to steel angles. In the realm of construction and manufacturing, steel angles hold a prevalent position and can effortlessly be tailored to meet the exact specifications of a particular project. This customization encompasses the ability to modify the length, width, and thickness of the steel angle in order to perfectly align with the desired dimensions. Through collaboration with a steel fabrication company or a metal supplier, clients can convey their precise measurements and requirements, enabling the creation of custom-made steel angles that precisely cater to the project's needs. This process ensures an impeccable fit and optimal performance, guaranteeing utmost satisfaction.

- Q: How do you determine the resistance to lateral-torsional buckling of a steel angle?

- There are several factors that need to be taken into account when determining the resistance to lateral-torsional buckling of a steel angle. The primary factors that influence this resistance are the geometric properties of the angle section, the material properties of the steel, and the boundary conditions of the member. 1. Geometric properties: The resistance to lateral-torsional buckling is affected by critical geometric properties such as the length, width, thickness, and slenderness ratio of the angle section. The slenderness ratio, which is the ratio of the length to the radius of gyration of the section, is particularly important as it indicates the stability of the member. A higher slenderness ratio implies a greater susceptibility to lateral-torsional buckling. 2. Material properties: The resistance to lateral-torsional buckling also depends on the material properties of the steel angle. Factors such as the yield strength, modulus of elasticity, and the shape of the stress-strain curve play a significant role in determining the capacity of the steel angle to withstand bending and twisting moments without buckling. 3. Boundary conditions: The resistance to lateral-torsional buckling is significantly influenced by the boundary conditions of the steel angle. The type of support and the loading conditions both play a crucial role. The type of support, whether it is simply supported or fixed, determines the level of rotational and translational constraints on the member. Similarly, the applied loads, such as point loads, distributed loads, or moments, determine the bending and twisting moments that act on the angle section. To determine the resistance to lateral-torsional buckling, engineers typically refer to relevant design codes and standards, such as the AISC Manual or Eurocode. These codes provide design formulas and tables that take into consideration the geometric properties, material properties, and boundary conditions. They allow engineers to calculate the critical moment and corresponding resistance to lateral-torsional buckling for the steel angle. Additionally, advanced computer simulations, such as FEA software, can be used to obtain more accurate results by considering complex loadings and boundary conditions.

- Q: How are steel angles protected against abrasion?

- Steel angles can be protected against abrasion through various methods, such as applying anti-abrasion coatings, using rubber or plastic lining, or incorporating sacrificial wear plates. These protective measures help to minimize the wear and tear caused by friction and ensure the longevity and durability of the steel angles.

Send your message to us

Equal Angle Steel Hot Rolled SS400-SS540 Series

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords