Equal Steel Angle S235JR Hot Rolled Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | In bundles and load in container, if large quantity, ship by bulk vessel. Also can be done according to customer's request |

| Delivery Detail: | Within 30 days after receipt of L/C or deposit by T/T |

Specifications

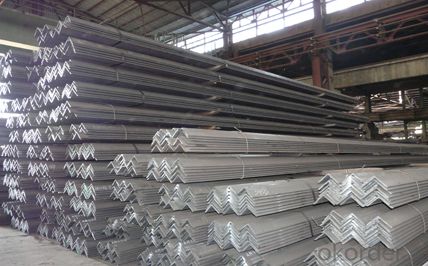

S235jr hot rolled equal steel angle

1.Grade:A36,Q235,SS400

2.Surface:galvanized,black,painted

3.Type: equal & unequal

1.Product Description

Products | S235jr hot rolled equal steel angle |

Grade | Q235,SS400B,A36,S255JR.ect |

Specification | 20*20--200*200mm. |

Length | 6m, 12m |

Technique | Hot rolled |

Application | Widely used in various building structure and engineering structure, such as the beam, bridges, transmission tower, lifting transportation machinery, ship, industrial furnace, reaction tower, container frame and warehouse.etc |

Payment | 100% irrevocable L/C at sight 30% T/T prepaid and the balance against the copy of B/L |

Reference sizes,

Size | Weight | Size | Weight | Size | Weight |

(mm) | (kg/m) | (mm) | (kg/m) | (mm) | (kg/m) |

25*3 | 1.124 | 70*6 | 6.406 | 100*16 | 23.257 |

25*4 | 1.459 | 70*7 | 7.398 | 110*8 | 13.532 |

30*3 | 1.373 | 70*8 | 8.373 | 110*10 | 16.69 |

30*4 | 1.786 | 75*5 | 5.818 | 110*12 | 19.782 |

40*3 | 1.852 | 75*6 | 6.905 | 110*14 | 22.809 |

40*4 | 2.422 | 75*7 | 7.976 | 125*8 | 15.504 |

40*5 | 2.967 | 75*8 | 9.03 | 125*10 | 19.133 |

50*3 | 2.332 | 75*10 | 11.089 | 125*12 | 22.696 |

50*4 | 3.059 | 80*6 | 7.736 | 125*14 | 26.193 |

50*5 | 3.77 | 80*8 | 9.658 | 140*10 | 21.488 |

50*6 | 4.465 | 80*10 | 11.874 | 140*12 | 25.522 |

60*5 | 4.57 | 90*8 | 10.946 | 140*14 | 29.49 |

60*6 | 5.42 | 90*10 | 13.476 | 160*12 | 29.391 |

63*4 | 3.907 | 90*12 | 15.94 | 160*14 | 33.987 |

63*5 | 4.822 | 100*8 | 12.276 | 160*16 | 38.518 |

63*6 | 5.721 | 100*10 | 15.12 | 160*18 | 48.63 |

63*8 | 7.469 | 100*12 | 17.898 | 180*18 | 48.634 |

70*5 | 5.397 | 100*14 | 20.611 | 200*24 | 71.168 |

2.Packaging & Shipping:

In bundles, load into container, if large quantity, ship by bulk vessel.

3. Relevant product pictures:

- Q: How do steel angles contribute to the overall lateral stability of a structure?

- Steel angles contribute to the overall lateral stability of a structure by providing structural support and resistance against horizontal forces or loads. These angles, when properly placed and connected, help to distribute these forces and prevent any excessive movement or deformation of the structure. They act as braces or reinforcements, increasing the overall rigidity and strength of the structure, thereby enhancing its ability to withstand lateral loads and maintain stability.

- Q: How do you calculate the load capacity of a steel angle?

- To calculate the load capacity of a steel angle, you need to consider several factors. Firstly, you need to determine the yield strength of the steel angle. This can be obtained from the manufacturer's specifications or by conducting tests. The yield strength is the maximum stress that the steel angle can withstand without permanent deformation. Next, you need to determine the moment of inertia of the angle section. The moment of inertia is a measure of the beam's resistance to bending. It can be calculated using the formula: I = (b * h^3) / 12, where b is the width and h is the height of the angle section. Once you have the yield strength and moment of inertia, you can use the formula for bending stress: σ = (M * c) / I, where σ is the bending stress, M is the applied moment, and c is the distance from the centroid to the extreme fiber. To calculate the load capacity, you need to consider the safety factor. The safety factor accounts for uncertainties and variations in loading conditions. It is typically specified by the design code or standard being used. To determine the load capacity, divide the bending stress by the safety factor: Load Capacity = σ / Safety Factor. It is important to note that the load capacity calculation assumes that the steel angle is perfectly straight, with no defects or imperfections. In real-world applications, additional factors such as residual stress, temperature effects, and dynamic loading should also be considered. It is recommended to consult with a structural engineer or refer to design codes and standards specific to your application to ensure accurate calculations.

- Q: What are the different types of steel angles used in material handling equipment?

- There are several different types of steel angles that are commonly used in material handling equipment. These angles are typically used to reinforce and provide structural support to the equipment, ensuring its stability and strength. One type of steel angle commonly used in material handling equipment is the equal angle. This angle has equal sides and is often used to create frames or supports in equipment such as conveyors, cranes, and lifting devices. The equal angle provides stability and structural integrity, making it a reliable choice for heavy-duty applications. Another type of steel angle used in material handling equipment is the unequal angle. As the name suggests, this angle has unequal sides, with one side being longer than the other. The unequal angle is often used in equipment where a specific angle or slope is required, such as ramps, inclined conveyors, or equipment with adjustable height mechanisms. The unequal angle allows for customization and flexibility in design. Additionally, there are steel angles with specific profiles that are designed for specialized applications in material handling equipment. For example, the L-shaped angle is commonly used as a corner bracket or reinforcement in equipment such as shelving units, racks, and pallets. The T-shaped angle, on the other hand, is often used as a support or bracket for attaching additional components or accessories to the equipment. It's worth noting that the choice of steel angle in material handling equipment depends on various factors, such as the weight capacity, load distribution, environmental conditions, and design requirements of the equipment. Engineers and manufacturers carefully consider these factors to select the most suitable type of steel angle for each specific application, ensuring the equipment's safety, durability, and efficiency.

- Q: Are steel angles resistant to dynamic loads?

- Yes, steel angles are generally resistant to dynamic loads. Due to their structural properties and high strength-to-weight ratio, steel angles can effectively withstand dynamic forces such as vibrations, impacts, and other fluctuating loads without significant deformation or failure. However, the specific resistance to dynamic loads may vary depending on the size, grade, and design of the steel angle.

- Q: Can steel angles be used for overhead cranes?

- Yes, steel angles can be used for overhead cranes. Steel angles provide structural support and stability to the crane, making them a suitable choice for constructing the framework of overhead cranes. They are strong, durable, and capable of withstanding heavy loads, making them an ideal material for such applications.

- Q: Can steel angles be used for framing partitions and walls?

- Yes, steel angles can be used for framing partitions and walls. Steel angles are commonly used in construction for their strength and durability, making them suitable for framing applications. They provide structural support and stability, making them a reliable choice for framing walls and partitions in various building projects.

- Q: How do you calculate the weight of a steel angle?

- In order to determine the weight of a steel angle, one must have knowledge of its dimensions and the density of steel. The weight of an object can be determined by using the equation: Weight = Volume × Density For a steel angle, the volume can be obtained by multiplying the cross-sectional area of the angle by its length. The cross-sectional area of the angle can be calculated by multiplying its width by its height. Once the volume is determined, it can be multiplied by the density of steel to find the weight. Let's consider an example where a steel angle has a width of 3 inches, a height of 3 inches, and a length of 6 feet. The density of steel is typically around 7850 kg/m³ or 0.2836 lb/in³. To begin, calculate the cross-sectional area: Area = width × height Area = 3 in × 3 in Area = 9 in² Next, compute the volume: Volume = Area × length Volume = 9 in² × 6 ft × 12 in/ft Volume = 648 in³ Finally, determine the weight: Weight = Volume × Density Weight = 648 in³ × 0.2836 lb/in³ Weight = 183.9828 lb Hence, the weight of the steel angle would be approximately 183.98 pounds.

- Q: Are steel angles corrosion-resistant?

- Yes, steel angles are corrosion-resistant due to the protective oxide layer that forms on their surface, which helps prevent rusting and degradation.

- Q: Can steel angles be customized to specific dimensions?

- Yes, steel angles can be customized to specific dimensions. Steel angles are commonly used in construction and manufacturing industries, and they can be customized to meet the specific requirements of a project. This customization can include altering the length, width, and thickness of the steel angle to fit the desired dimensions. By working with a steel fabrication company or a metal supplier, customers can provide their specific measurements and requirements, and the steel angles can be custom-made accordingly. This ensures that the steel angles are tailored to the needs of the project, providing a precise fit and optimal performance.

- Q: What are the different types of steel angles connections for columns?

- Columns in construction can utilize various steel angle connections. 1. Bolted Angle Connection: A commonly employed joint involves fastening steel angles using bolts and plates, ensuring a sturdy and dependable connection to the column. 2. Welded Angle Connection: Steel angles can be directly welded to the column, offering exceptional strength and stiffness, making them suitable for heavy-duty applications. 3. Gusset Plate Connection: A flat plate, known as a gusset plate, is affixed to the column and steel angles to establish a connection. This plate may be bolted or welded to enhance strength and stability. 4. Cleat Connection: For smaller columns, a cleat, a small steel piece, can be bolted or welded to the column and steel angles, providing a straightforward and cost-effective solution. 5. Moment Connection: Designed to withstand axial and bending loads, a moment connection involves the welding or bolting of steel angles to the column. Additional reinforcing plates and stiffeners are incorporated to ensure the necessary strength and rigidity. 6. Eccentric Connection: Used when the load is applied off-center to the column, an eccentric connection involves attaching steel angles to the column in an offset position to account for the eccentric load. Ultimately, the selection of a steel angle connection for columns depends on factors such as load requirements, structural design, and construction methods. It is crucial to consider the project's specific needs and consult with a structural engineer to determine the most appropriate connection type.

Send your message to us

Equal Steel Angle S235JR Hot Rolled Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords