Colored Aluminum Sheets Racing - Two Bars Embossed Aluminum Plate with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Two Bars Embossed Aluminum Plate Description:

They are widely used in construction and decoration, hardware and electric appliances manufacture, automobile manufacture and other industrial and civil purposes, such as electronic capacitor, rice cooker, refrigerator, computer casting, lamp shade, air-conditioner, cosmetics cover and box, air-conditioner radiator, inner container of disinfecting cabinet, ceiling board, automobile motherboard, cover board and top board, etc.

2.Main Features of Two Bars Embossed Aluminum Plate :

Aluminum Alloy Grade: 1050, 1060, 1100, 3003, 5052

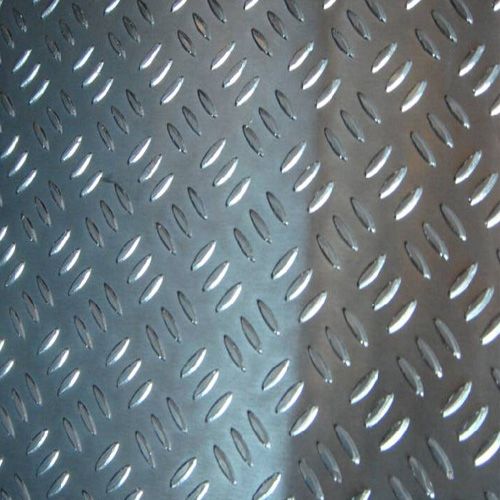

Pattern: 2 bars, 3 bars, 5 bars, diamond bars, stucco embossed, compass embossed and so on

Thickness: 1.0mm-6.0mm

Width: Under 1600mm

3. Two Bars Embossed Aluminum Plate Images:

4. Two Bars Embossed Aluminum Plate Specification:

| Aluminum Alloy Grade | 1050, 1060, 1100,3003, 3105,5005 |

| Pattern | 2 bars, 3 bars, 5 bars, diamond bars, stucco embossed, compass embossed and so on |

| Thickness | 1.0mm-6.0mm |

| Width | Under 1300mm |

| Length | Under 4200mm or coil size according to customer's requirement |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: How does the surface finish of aluminum sheet affect its cleaning requirements?

- The surface finish of aluminum sheet can greatly impact its cleaning requirements. A smooth and polished surface finish tends to be more resistant to dirt, stains, and corrosion, making it easier to clean. On the other hand, a textured or rough surface finish can trap dirt and debris, requiring more effort and specialized cleaning techniques to remove them effectively. Additionally, specific surface finishes may be more prone to scratching or damage during cleaning, necessitating a more gentle approach. Overall, the surface finish of aluminum sheet directly influences the cleaning method and effort needed to maintain its appearance and functionality.

- Q: Are aluminum sheets suitable for artistic sculptures?

- Aluminum sheets, indeed, prove to be a suitable choice for artistic sculptures. Boasting versatility, aluminum offers numerous benefits for sculpting endeavors. First and foremost, its lightweight nature makes it easier for artists to handle and manipulate. This quality grants them the ability to fashion intricate and detailed sculptures without compromising on structural integrity. Moreover, aluminum possesses high malleability, allowing it to be molded into diverse forms and contours. This grants artists the freedom to experiment with various designs and achieve their desired artistic expression. Additionally, aluminum's resistance to corrosion and weathering makes it an ideal material for outdoor sculptures. Its durability ensures that the artwork will withstand the elements and maintain its aesthetic appeal over time. Furthermore, aluminum sheets can be effortlessly welded or joined together, enabling artists to create larger and more intricate sculptures. All in all, aluminum sheets furnish artists with a flexible and long-lasting material that nurtures creativity and guarantees longevity in their sculptural masterpieces.

- Q: Are aluminum sheets suitable for HVAC ductwork?

- Yes, aluminum sheets are suitable for HVAC ductwork. Aluminum is a lightweight and durable material that is resistant to corrosion, making it an ideal choice for ductwork systems. Additionally, aluminum sheets can be easily shaped and fabricated to meet specific design requirements, making them a popular choice in the HVAC industry.

- Q: Other then pop cans, what else is aluminum that can be recycled?

- all of it.

- Q: This question asks for guidance on selecting aluminum sheets based on their intended use, implying a need for criteria or factors to consider when making such a choice.

- <p>When choosing aluminum sheets for different purposes, consider the following factors: 1) Thickness: Depending on the strength and durability required, select the appropriate thickness. 2) Alloy Type: Different alloys have varying properties; for instance, 1100 series is purest and softest, while 6000 series offers high strength. 3) Surface Finish: Choose between mill finish, anodized, or coated finishes based on aesthetic and functional needs. 4) Temper: This refers to the hardness and strength, with options like O (annealed), H14 (strain hardened), and T6 (solution heat treated). 5) Application: Consider the specific use, such as construction, automotive, or aerospace, as each may require specific properties. Always consult with a supplier or engineer for advice tailored to your project's needs.</p>

- Q: What are the different surface finishes for aluminum sheets in the aerospace industry?

- In the aerospace industry, aluminum sheets are commonly used in the construction of aircraft structures due to their lightweight and high strength properties. To enhance their durability, protect against corrosion, and improve aesthetic appeal, various surface finishes can be applied to aluminum sheets. One of the most commonly used finishes is anodizing, which involves electrolytically coating the aluminum with a protective oxide layer. This process not only improves corrosion resistance but also provides a range of color options and enhances the sheet's ability to accept adhesives. Another popular finish is alclad, which involves bonding a thin layer of pure aluminum to both sides of an alloy sheet. This not only provides excellent corrosion resistance but also allows for better bonding with composite materials. In addition to anodizing and alclad, other surface finishes used in the aerospace industry include chemical conversion coatings, which provide corrosion resistance and improve paint adhesion, and mechanical finishes such as grinding or brushing, which can be used for aesthetic purposes or to prepare the surface for further treatment. Furthermore, some specialized finishes are employed for specific applications. For instance, in areas where high wear resistance is required, hard anodizing can be used to create a durable, wear-resistant surface. For parts that require low friction or high lubricity, a Teflon coating or dry film lubricant can be applied. The choice of surface finish for aluminum sheets in the aerospace industry depends on the specific requirements of the application, including factors such as corrosion resistance, adhesion properties, wear resistance, and aesthetic preferences.

- Q: answer them please! i need help. the main question is # 1!!! 2. how many atoms are in one particle of aluminum dichromate?3. how many phosphorus atoms are in one particle of calcium phosphate?4. how many total atoms are in one particle of calcium phosphate?PLEASE!! who ever answers all, ill give them best answer a 5 star ratinggg. please!!! THANK YOU!

- 1) Look at the formula for aluminum nitrate [Al(NO3)3]. The subscript of 3 outside of the parentheses means that you multiply each atom inside the parentheses by 3. Since there is only one nitrogen inside the parentheses, this means that you multiply that by 3. There are a total of 3 nitrogen atoms in each molecule of aluminum nitrate. 2) The formula for aluminum dichromate is Al2(Cr2O7)3. Again, multiply each atom in the parentheses by 3, add them, then add 2 to that number for the aluminum. That's your answer. 3) The formula for calcium phosphate is Ca3(PO4)2. Multiply P by 2. 4) Follow the same steps as in #2, above.

- Q: Can aluminum sheets be used for insulation jackets?

- Yes, aluminum sheets can be used for insulation jackets. Aluminum is a good choice for insulation jackets as it is lightweight, durable, and has excellent thermal conductivity. It can effectively reflect heat and prevent heat transfer, making it an efficient material for insulation purposes.

- Q: Are the aluminum sheets suitable for manufacturing architectural column covers?

- Yes, aluminum sheets are suitable for manufacturing architectural column covers. Aluminum is a lightweight yet durable material that offers excellent corrosion resistance, making it ideal for exterior applications such as column covers. It can be easily shaped, bent, and fabricated to create custom designs and sizes, allowing for versatility in architectural projects. Additionally, aluminum sheets can be finished with various coatings, such as powder coating or anodizing, to enhance their aesthetic appeal and provide additional protection against weathering and wear. Overall, aluminum sheets provide a great combination of strength, versatility, and aesthetics, making them a suitable choice for manufacturing architectural column covers.

- Q: Can aluminum sheet be used for automotive heat shields?

- Indeed, aluminum sheet is a suitable option when it comes to automotive heat shields. The automotive industry favors aluminum due to its impressive thermal conductivity and remarkable heat resistance. By reflecting and dispersing heat away from specific regions, it effectively safeguards delicate components from excessive temperatures. Moreover, aluminum possesses the advantages of being lightweight and resistant to corrosion, rendering it an optimal choice for automotive purposes. It finds widespread utilization in diverse heat shield configurations, encompassing exhaust, engine, and under-carriage heat shields.

Send your message to us

Colored Aluminum Sheets Racing - Two Bars Embossed Aluminum Plate with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords