Aluminum Sheets for Racing:Best Price Aluminium Plate and Sheet in Warehouse

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Product Description

aluminum sheet is widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5000 series, 6000series,7000series,8000 series,etc. The detailed grade are as follows: 1010, 1050,1060,1100, 2024, 3003, 3005, 3105, etc.

The temper is include H14, H22, H24, H44,H112,O, H114,etc.

2. Main features of the product

a.Competitive price

c. Shortest service.

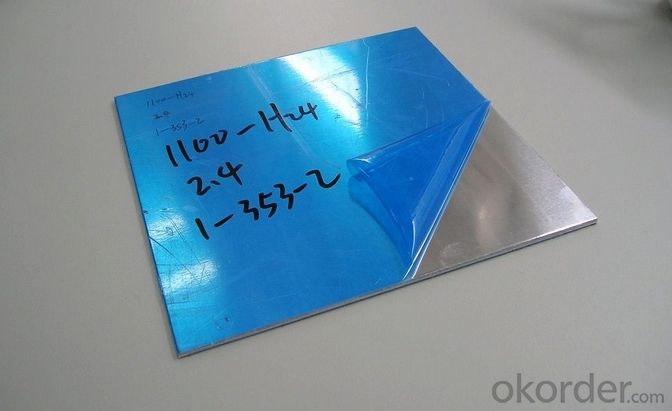

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm, 1250mm*2500mm, at random sizes,etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 2000mm to 6000mm, etc.

What is the MOQ for your products yet?

---Normally it is around 5 tons/each size.

How many tons did you export in one year

Japan, Vietnam, Singapore,Turkey,Fiji, etc.

What is your mainly products?

---Normally they are aluminum sheet,mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: How many molecules are in 1 square foot of aluminum foil?

- Since aluminum foil is an amalgamation of various metals you would first need to know the full chemical breakdown in order to determine how many molecules there are in a square foot of aluminum foil. That said, if your foil was 100% aluminum, you could determine the number of AL atoms by first determining the mass of the foil and dividing by the molecular weight of AL. Multiply that by 6.022 x 10^23 to determine the number of atoms.

- Q: What kind of material is 2A12 aluminum sheet?

- The temperature is higher than 125 degrees C, and the strength of the 2024 alloy is higher than that of the 7075 alloy. Under the condition of hot state, annealing and new quenching, the formability is better, and the strengthening effect of heat treatment is remarkable, but the heat treatment process is strict.

- Q: What does 1060h/24 mean in aluminium alloy?

- Each digit in the 1060-H24 stands for the following meanings:First, a number of Arabia 1 is representative of pure aluminum (aluminum is aluminum content above 99% aluminum, in addition to the beginning and start with 2-8 are 2### for copper and aluminum magnesium alloy, 3### aluminum manganese alloy, 4### alloy, 5### alloy and so on)Two, second, Arabia number 0, said the original alloy, such as 1, said the original alloy after a modification, 2 means that the original alloy after two modificationsThree, third and four 60 two Arabia data represent the value behind pure aluminum content of 99% per cent in pure aluminum, said 60 pure aluminum aluminum content of 99.60%, as the standard 1050 indicates the aluminum content of pure aluminum, 99.50% of the 1070 said that the aluminum content of 99.70% pure aluminum alloy in the back. In two the number of Arabia aluminum has no special meaning, is only used to identify the different alloys in the same group, said its second modifications.Four, H24 H said the work hardening of the state, and some do not have H but T said it is heat treatment.24 machining process control hardness and other properties, in addition to 24 and 12, 14, 16, 18, 22, 26, 34, 36 and so on, usually at the end of 4 is a semi hard state.1060O, 1060-H22, 1060-H24, 1060-H18 state is arranged from soft to hard.

- Q: Are 101 aluminum sheets suitable for marine environments?

- No, 101 aluminum sheets are not suitable for marine environments as they lack sufficient corrosion resistance.

- Q: What are the different machining options for aluminum sheets?

- Depending on the specific requirements of the project and the desired outcome, there are several machining options available for aluminum sheets. Some commonly used methods for machining aluminum sheets include: 1. Cutting: Aluminum sheets can be cut using various techniques such as shearing, sawing, or laser cutting. Shearing involves applying high force with a shearing machine to achieve a clean and straight cut. Sawing utilizes a saw blade to cut through the aluminum sheet, while laser cutting uses a high-powered laser beam to melt or vaporize the aluminum for precise and accurate cuts. 2. Drilling: Drilling is a frequently employed machining option to create holes in aluminum sheets. This process involves using a drill bit to remove material from the sheet and create holes with the desired diameter. Different drill bits can be utilized to achieve specific hole sizes and shapes. 3. Milling: Milling is a versatile machining option that can be used to create intricate shapes and contours in aluminum sheets. This process involves using a rotating cutting tool to remove material from the sheet, resulting in precise and accurate finishes. Depending on the project's complexity, milling can be performed using various types of milling machines, such as vertical milling machines or CNC milling machines. 4. Turning: Turning is another machining option commonly employed for aluminum sheets, particularly when shaping cylindrical or conical forms. This process involves rotating the aluminum sheet against a cutting tool, which removes material and shapes the sheet according to the desired dimensions. Turning can be carried out manually on lathes or using CNC turning machines for higher precision. 5. Bending: Bending is a frequently used machining option to create curved or angled shapes in aluminum sheets. This process involves applying force to the sheet, causing it to deform and take on the desired shape. Bending can be done manually using tools like a brake press or using hydraulic or CNC press brakes for more accurate and consistent results. These are just a few of the machining options available for aluminum sheets. The choice of method will depend on factors such as the desired outcome, project complexity, and available resources. It is crucial to select the most suitable machining option to efficiently and effectively achieve the desired results.

- Q: Can aluminum sheets be easily shaped or bent?

- Indeed, aluminum sheets possess a remarkable capability to be effortlessly molded or flexed. Renowned for its exceptional malleability and ductility, aluminum exhibits a remarkable propensity to be readily fashioned into diverse contours and curves. The manipulation of this versatile metal can be accomplished through an assortment of techniques, encompassing rolling, pressing, and even manual utilization of tools. Given its pliability, aluminum emerges as the preferred choice within industries such as automotive, aerospace, and construction, wherein the fabrication of intricate shapes and bends is a common necessity. Moreover, the lightweight nature and inherent resistance to corrosion further enhance aluminum's suitability for shaping and bending endeavors.

- Q: The real bumper/ reinforcement bar that is behind the plastic bumpers. Magnet don't stick to it and it don't rust which both types of metal are pretty much like that.

- i agree, the main bumper support under the plastic bumper skin, is aluminum.

- Q: What are the different methods of surface preparation for aluminum sheet?

- Depending on the desired finish and purpose, there are various approaches to preparing aluminum sheet surfaces. 1. Chemical Cleaning: To eliminate dirt, grease, and contaminants, chemical solutions are employed. The sheet is typically soaked in the cleaning solution and thoroughly rinsed to ensure complete removal of any residues. 2. Mechanical Cleaning: Imperfections or coatings are removed through mechanical processes like sanding, grinding, or brushing. Abrasive materials or tools are used for sanding or grinding, while wire brushes are employed for brushing. 3. Etching: A textured finish that enhances adhesion for subsequent coatings or finishes is achieved through the application of acid or alkaline solutions to the aluminum sheet. This process removes a thin layer of the metal, creating a rough surface. 4. Anodizing: By immersing the sheet in an electrolytic solution and passing an electric current through it, an oxide layer is formed on the aluminum sheet. Anodizing not only improves the appearance but also provides protection against corrosion. 5. Conversion Coating: The surface of the aluminum sheet is converted into a more corrosion-resistant material through chemical processes like chromate or phosphate conversion coating. These coatings offer additional protection and improve the bonding of subsequent coatings. Each method of surface preparation for aluminum sheet has distinct advantages and is selected based on specific requirements. It is crucial to choose the appropriate method to ensure proper adhesion of coatings and finishes, as well as to enhance the overall durability and appearance of the aluminum sheet.

- Q: which kind of enterprises are aluminium sheet circles used in?

- user use cold squezz method to transform the aluminum sheet circle into various standard capacitor shell, aluminium collapsible tube shell, which are broadly used in electron industry, daily chemical industry, medicine, education and automobile products,electrical appliance, heat preservation, machine manufacturing, automobile,spaceflight,military industry,mould, construction, printing and other industries.

- Q: Are aluminum sheets suitable for automotive body framing?

- Yes, aluminum sheets are suitable for automotive body framing. Aluminum is lightweight, corrosion-resistant, and offers excellent strength-to-weight ratio, making it an ideal choice for reducing vehicle weight and improving fuel efficiency. It is commonly used in modern automotive manufacturing for body panels and frames, providing structural integrity while maintaining durability.

Send your message to us

Aluminum Sheets for Racing:Best Price Aluminium Plate and Sheet in Warehouse

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords