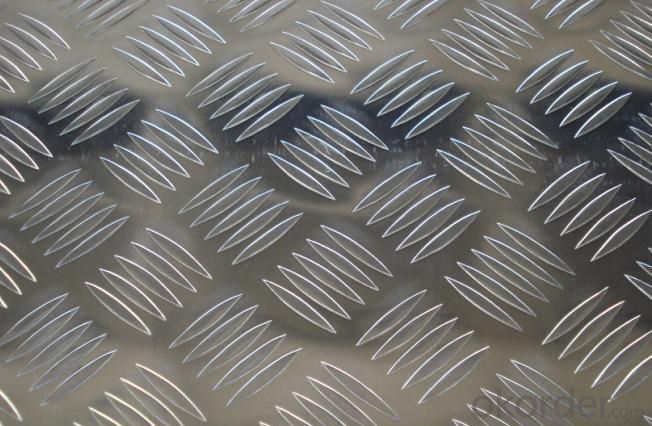

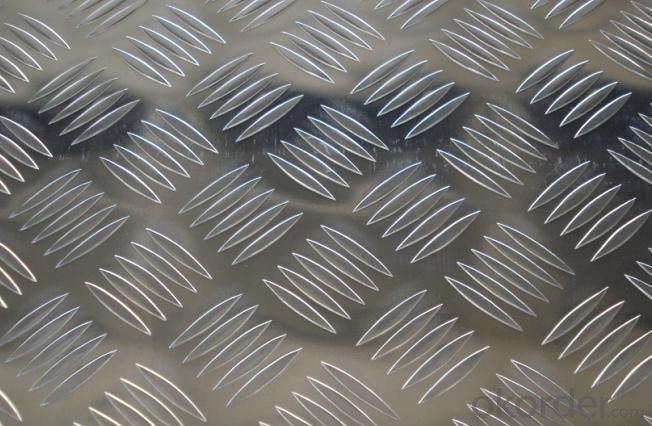

Race Car Aluminum Sheets - Decorative Embossed Aluminum Sheet from Mill

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Alloy | 1100/1050,1060,1070,3003,3105,5052,5083,8011 | ||

Temper | O, H12,H14,H16,H18,H22,H24,H26,H32 etc | ||

Specification | Thickness(mm) | 0.1mm-3.0mm | |

Width(mm) | 20mm-2200mm | ||

Application | Roofing, Refrigerator, ornamental and decoration, etc | ||

Inner Diameter(MM): | 75/150/200/310/505 | Standard: | GB/T3190-1999.GB/T3190-2003. YS/T430-2000 |

Surface Treatment | two bars/ three bars/ five bars/ stucco | ||

Origin | China | ||

Payment | 30% by TT in advance as deposit and 70% balance by TT or L/C at sight | ||

Lead Time | Within 10-25 days after receiving deposit or L/C copy | ||

Packaging & Shipping

1. For sheet, 18-20MT can be loaded into 20 foot container, we try to use 20 foot container, the sea freight rate is much cheaper than 40 foot container.

2. The packing is very strong, which has 3 lays, thick fiber, foam, plastic, enough drying agent, suitable for long distance sea transportation.

The application of the embossed aluminum sheet/coils:it is widely used in air-conditioning,cable,exchanger, cigarettes,food,medicine,decoration,packing, electrical,electric products and etc.

- Q: Can anyone tell me what to be careful of if you have aluminum wiring in your house. I was told that if the wall gets hot, I need to tighten the screws of the inside switch. Is this true and if I didn't, would it actually cause a fire in the wall. If this is true, how often does it loosen?

- There are several ways to take care of your problem. 1) Change all the wiring to copper. 2) Pigtail with copper wire and al/cu wirenuts to all new devices 3) Use copalum at all your boxes (this method is the best, besides replacing all your wiring to copper). Basically it cold welds the aluminum to the copper and makes a molecular bond. It's pretty expensive, and you'll have to look to find someone that actually knows how to do it, and has access to the crimping tool. Going around and tightening your devices won't hurt, but won't be fixing any longer term issues you may have with the aluminum wire. Keep in mind that if the original installation was done correctly, your circuits aren't overly tapped, and all the wires are on the appropriately sized breakers, then you may not have to worry much. Just run dedicated lines to any your new circuits. In other words, don't tap off these circuits. Hope this helps.

- Q: What is the coefficient of thermal expansion of aluminum sheets?

- The coefficient of thermal expansion of aluminum sheets is typically around 23 x 10^-6 per degree Celsius.

- Q: What are the common thicknesses available for aluminum sheets?

- The common thicknesses available for aluminum sheets range from 0.006 inches to 0.25 inches, with standard options including 0.016, 0.020, 0.025, 0.032, 0.040, 0.050, and 0.063 inches.

- Q: What are the different bending methods for aluminum sheets?

- Aluminum sheets can be bent using different methods, each with its own advantages and limitations. Various bending techniques for aluminum sheets include: 1. Air Bending: By utilizing a punch and die, a bend is formed in the aluminum sheet without direct contact. Compressed air is employed to exert force on the sheet, resulting in the desired bend. Air bending is a versatile method that allows for a range of bend angles and radii. 2. Bottom Bending: This method involves clamping the aluminum sheet between a V-shaped die and a flat die. A punch is then used to press the sheet into the V-shaped die, creating the desired bend. Bottom bending is suitable for achieving sharp bends with small radii. 3. Coining: Precise and crisp bends are formed by applying high pressure to the aluminum sheet between a punch and a die. Coined bends exhibit minimal springback. However, this method requires specialized equipment and is typically utilized for high-volume production. 4. Roll Bending: By passing the aluminum sheet between a set of rollers, it is gradually bent into the desired shape. Roll bending is commonly employed for creating cylindrical or conical shapes. This technique can achieve large radii and is suitable for thicker aluminum sheets. 5. Press Brake Bending: This commonly used method employs a hydraulic or mechanical press brake to create bends in aluminum sheets. The sheet is clamped between a punch and a die, and the press brake applies force to create the bend. Press brake bending offers flexibility in terms of bend angles and radii. It is important to consider various factors such as the desired bend angle, radius, material thickness, and specific application requirements when selecting a bending method.

- Q: Fiber laser cutting machine and carbon dioxide laser cutting machine, which thin aluminum plate effect is better?

- Carbon dioxide laser cutting edge, a little black, if it is to use optical fiber, the cutting effect is more beautiful, but it also depends on your needs, our fiber laser cutting machine and carbon dioxide laser cutting machine have, can come to visit Hummer laser

- Q: Are aluminum sheets suitable for food processing conveyor systems?

- Aluminum sheets are a great choice for food processing conveyor systems as they offer several advantages. Firstly, they are lightweight yet strong, making them perfect for conveyor systems that require frequent movement and transportation of food products. Their lightweight nature allows for easy installation, maintenance, and modification of conveyor systems, while their strength ensures the equipment's durability and longevity. Secondly, aluminum is corrosion-resistant, which is crucial in food processing environments where exposure to moisture, chemicals, and food acids is common. This resistance to corrosion ensures that the conveyor system remains hygienic and free from contamination, meeting the industry's strict food safety standards. Furthermore, aluminum is non-toxic, making it a safe material for food handling and contact. It does not react with food or release any harmful substances, ensuring the integrity and safety of the food being processed on the conveyor system. Moreover, aluminum is easy to clean and maintain, which is essential in food processing environments where hygiene is of utmost importance. The smooth and non-porous surface of aluminum sheets allows for easy removal of food particles, grease, and other contaminants, reducing the risk of bacterial growth and cross-contamination. In conclusion, aluminum sheets are highly suitable for food processing conveyor systems due to their lightweight, corrosion-resistant, non-toxic, and easy-to-clean properties. They provide a reliable and efficient means of transporting food products while ensuring the highest standards of hygiene and food safety.

- Q: Are aluminum sheets suitable for construction applications?

- Yes, aluminum sheets are suitable for construction applications. Aluminum is a lightweight and durable material that offers several advantages in construction projects. It has high strength-to-weight ratio, making it easy to handle and transport while still providing excellent structural integrity. Aluminum sheets are corrosion-resistant, which makes them ideal for outdoor applications. They can withstand exposure to harsh weather conditions, such as rain, snow, and UV rays, without deteriorating or rusting. This resistance to corrosion ensures the longevity of the construction project. In addition, aluminum sheets are highly malleable and can be easily shaped and formed into various sizes and designs. This versatility allows architects and designers to create unique and aesthetically pleasing structures. Aluminum sheets can be used for roofing, siding, cladding, and façade systems, as well as in the construction of windows, doors, and curtain walls. Moreover, aluminum is a sustainable material, as it is 100% recyclable and requires significantly less energy to recycle compared to other metals. This makes aluminum sheets a more environmentally friendly choice for construction projects. In summary, aluminum sheets are suitable for construction applications due to their lightweight, durability, corrosion resistance, malleability, and sustainability. Their versatility and aesthetic appeal make them an excellent choice for a wide range of construction projects.

- Q: heating can affect aluminium

- This is science so, if you want specific answers, you must ask specific questions. What type of aluminum are you interested in? What characteristics are important to you? What kind of factors are you talking about? You are right that heating can affect Al. In fact, heating affects, basically, everything, every material we know of and every physical and chemical process that we do and every process that happens in nature. Temperature is important in all of these. There are more than a hundred different commercial aluminum alloys and most of them are available in a variety of different tempers (heat treated conditions). The heat treatment of commercial Al alloys is a very important thing. If you want more specific information, consult your friendly neighborhood metallurgist.

- Q: Is it possible to use aluminum sheets as a material for exterior wall covering?

- <p>Yes, aluminum sheets can be used for exterior cladding. They are known for their durability, resistance to corrosion, and low maintenance requirements. Aluminum is lightweight, which makes it easier to install compared to heavier materials. It also has good thermal properties, helping to insulate buildings. Additionally, aluminum can be coated with various finishes, allowing for a wide range of aesthetic options. However, it's important to ensure proper installation and sealing to prevent water infiltration and to maintain the cladding's performance over time.</p>

- Q: Are aluminum sheets suitable for boat building?

- Yes, aluminum sheets are suitable for boat building. Aluminum is a popular material choice for boat construction due to its numerous advantageous properties. Firstly, aluminum is lightweight, which makes it easier to handle and transport during the boat building process. This lightweight characteristic also contributes to better fuel efficiency and improved overall performance of the boat. Additionally, aluminum is highly resistant to corrosion, especially in saltwater environments, making it an ideal choice for boat building. This resistance to corrosion ensures that the boat remains durable and maintains its structural integrity for a longer period of time, even when exposed to harsh weather conditions. Furthermore, aluminum sheets offer excellent strength-to-weight ratio, providing a sturdy and reliable structure for the boat. This strength allows the boat to withstand the forces encountered while sailing, ensuring a safe and enjoyable experience for the occupants. Moreover, aluminum is a versatile material that can be easily molded and shaped into various boat designs. This flexibility allows for customization and the creation of unique boat designs that meet specific requirements and preferences. Lastly, aluminum is a sustainable and environmentally friendly material. It is fully recyclable, reducing the environmental impact of boat building and promoting a greener approach to marine construction. In conclusion, aluminum sheets are indeed suitable for boat building due to their lightweight nature, corrosion resistance, strength, versatility, and eco-friendliness.

Send your message to us

Race Car Aluminum Sheets - Decorative Embossed Aluminum Sheet from Mill

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords