Top Grade Kitchen Cupboard Aluminum Profiles India

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft, durable, lightweight, ductileand malleablemetalwith appearance ranging from silvery to dull gray, depending on the surfaceroughness. It is nonmagnetic and does not easily ignite. A fresh film ofaluminium serves as a good reflector (approximately 92%) of visible lightand an excellent reflector (as much as 98%) of medium and far infraredradiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the densityand stiffness of steel. It is easily machined,cast, drawn and extruded.

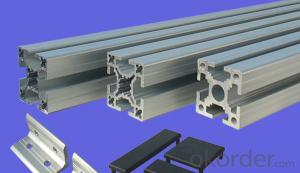

Features:

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

- Q: What are the necessary upkeep and care procedures for aluminum profiles post-installation?

- <p>After installation, aluminum profiles generally require minimal maintenance due to their corrosion resistance and durability. However, regular cleaning to remove dust and dirt is recommended to maintain their aesthetic appeal and performance. This can be done using mild detergents and water. Periodic inspection for any signs of damage or wear is also important to ensure the structural integrity of the profiles. In case of any damage, it should be promptly attended to to prevent further deterioration. Despite their low maintenance nature, it's crucial to follow the manufacturer's guidelines for care and upkeep to prolong the life of the aluminum profiles.</p>

- Q: This question asks about the various types of surface treatments or finishes that can be applied to aluminum profiles.

- <p>Aluminum profiles can be coated with different types of finishes to enhance their appearance, durability, and resistance to corrosion. Some common types of coatings include: 1. Anodizing, which creates a protective oxide layer on the surface. 2. Powder coating, a durable and colorful finish applied through an electrostatic process. 3. Electrophoretic coating, a method that uses electric current to apply a paint-like coating. 4. PVDF coating, a high-performance finish with excellent weather resistance. 5. Thermal spraying, which applies a coating through a high-velocity flame. 6. Vacuum coating, a process that deposits thin layers of material in a vacuum chamber. Each type of coating has specific properties and applications, making them suitable for different environments and uses.</p>

- Q: Can aluminum profiles be used for balustrades?

- Yes, aluminum profiles can be used for balustrades. Aluminum is a lightweight and durable material that is often used in construction and architectural applications, including balustrades. It offers strength, versatility, and a sleek appearance, making it a popular choice for both residential and commercial projects. Additionally, aluminum is resistant to corrosion, which makes it suitable for outdoor installations.

- Q: What is the difference between aluminum profile and sheet metal?

- Profile, as the name suggests, is a variety of complex shapes of aluminum, plates only flat type aluminum.

- Q: How do you prevent galvanic corrosion with aluminum profiles?

- To prevent galvanic corrosion with aluminum profiles, there are several steps that can be taken: 1. Use compatible materials: It is important to select materials that are compatible with aluminum to avoid galvanic corrosion. Avoid coupling aluminum profiles with dissimilar metals, such as copper, brass, or steel, as these combinations can accelerate the corrosion process. 2. Apply protective coatings: Applying a protective coating, such as anodizing or painting, can provide a barrier between the aluminum profiles and the surrounding environment. Anodizing creates a durable oxide layer on the surface of aluminum, which enhances its corrosion resistance. Painting with suitable corrosion-resistant paints can also provide an effective barrier against galvanic corrosion. 3. Insulate dissimilar metals: If it is necessary to use dissimilar metals in conjunction with aluminum profiles, it is crucial to insulate them from direct contact. This can be achieved by using gaskets, insulating materials, or non-conductive fasteners to separate the metals and prevent the electrical contact that causes galvanic corrosion. 4. Regular maintenance and cleaning: Regular cleaning and maintenance of aluminum profiles can help prevent galvanic corrosion. Removing any accumulated dirt, debris, or other contaminants from the surface can minimize the chances of corrosion initiation. 5. Control the environment: Controlling the environment in which aluminum profiles are used can also play a significant role in preventing galvanic corrosion. Avoid exposing aluminum to environments with high humidity, saltwater, or acidic conditions, as these can accelerate corrosion. Additionally, maintaining proper ventilation and moisture control can help minimize the risk of corrosion. By following these preventive measures, it is possible to significantly reduce the risk of galvanic corrosion and ensure the longevity and performance of aluminum profiles.

- Q: Can aluminum profiles be used in the construction of green buildings?

- Absolutely, aluminum profiles are certainly suitable for use in the construction of environmentally friendly buildings. Aluminum is a remarkably sustainable material that brings about a plethora of benefits for green building initiatives. To begin with, aluminum is a lightweight substance that facilitates easier transportation and handling during construction. Consequently, this reduces energy consumption and carbon emissions involved in transportation. Moreover, aluminum is highly recyclable. It can be melted down and reused without any compromise in quality, making it an ideal selection for sustainable construction. This recyclability also diminishes the need for extracting and processing new aluminum, consequently reducing the environmental impact. Additionally, aluminum boasts exceptional durability and resistance to corrosion, which means it can endure for an extended period without frequent maintenance or replacement. This, in turn, reduces the requirement for new materials and minimizes waste throughout the building's lifespan. Furthermore, aluminum profiles can be designed to enhance energy efficiency in green buildings. They can be utilized for windows, doors, and curtain walls, providing exceptional thermal insulation and minimizing heat loss or gain. This, in turn, diminishes the energy consumption necessary for heating or cooling the building, resulting in lower carbon emissions. Furthermore, aluminum is a non-toxic material that does not release harmful chemicals into the environment, ensuring a healthier indoor environment for occupants. In conclusion, aluminum profiles offer a multitude of advantages for green building construction. Their lightweight nature, recyclability, durability, energy efficiency, and non-toxicity make them an optimal sustainable choice for green building projects.

- Q: This question asks for a list of different types of fasteners that are typically used in conjunction with aluminum extrusions.

- <p>Common types of fasteners used with aluminum extrusions include: 1. T-nuts and T-bolts, which provide a secure way to mount components to the extrusion. 2. Clamps and brackets, which can be used to hold items in place without drilling. 3. Corner brackets, which are used to connect two extrusions at right angles. 4. End caps, which protect the ends of the extrusion and can also serve as a mounting point. 5. Dowel pins, which are used to align and secure extrusions together. 6. Spacers, which maintain a consistent distance between extrusions. 7. Adhesives, which can be used for bonding parts to the extrusion. 8. Rivets, which provide a permanent connection between extrusions and other materials. These fasteners are chosen based on the specific application, load requirements, and design considerations.</p>

- Q: What are the minimum thickness specifications for aluminum alloy door and window profiles?

- 1, aluminum alloy doors and windows, curtain wall profiles, thickness GB8478, 2008, "aluminum alloy window" 5.1: aluminum alloy window force components should be determined by test or calculation. The minimum measured wall thickness shall be greater than 1.4mm without the surface treated profiles.

- Q: This question asks about the various techniques used to install aluminum profiles in construction projects.

- <p>There are several methods for installing aluminum profiles in construction: 1. Direct Fixing: Using screws or bolts directly into the aluminum profile. 2. Mortise and Tenon Joints: Joining profiles with a slot and a protruding part that fits into it. 3. Welding: Joining aluminum profiles using heat to melt and fuse them together. 4. Adhesive Bonding: Using adhesives to bond aluminum profiles together. 5. Mechanical Fasteners: Using nuts, bolts, and other fasteners to join profiles. 6. Clipping: Attaching profiles using clips or clamps. 7. Slot and Pin: A system where a pin fits into a slot in the profile. Each method has its advantages and is chosen based on the specific requirements of the construction project, such as load-bearing needs, aesthetic considerations, and ease of installation.</p>

- Q: Can aluminum profiles be used in the production of automotive interiors?

- Yes, aluminum profiles can be used in the production of automotive interiors. Aluminum profiles offer lightweight, durable, and corrosion-resistant properties, making them suitable for various interior components such as door panels, dashboard trims, seat frames, and console accents. Additionally, aluminum profiles can be easily customized and integrated with other materials, allowing for innovative designs and improved functionality in automotive interiors.

Send your message to us

Top Grade Kitchen Cupboard Aluminum Profiles India

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords