High Quality Aluminum H Extrusion Profiles for Kitchenware

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

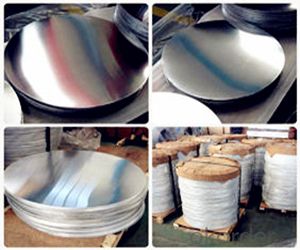

Aluminum Circles for Kitchenware

Aluminum Circles Specification

Alloy: 1050, 1060, 1070, 3003, 5052, 3105, 6061

thickness:0.15-8mm

diameter: 20-1200mm

Aluminum Circles Application

aluminum circle Tolerance: thickness tolerance +/-3%, diameter tolerance +/-1%mm

Deep drawing cookware, spinning cookware, road sign, Building Material,Insulation, and so on.

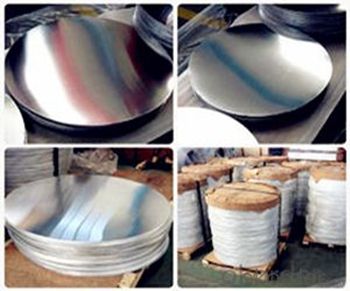

Aluminum Circles Picture

Aluminum Circles Features

1.Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use.

2.Chemical Composite and Mechanical Property could meet the requirements of GB/T, ASTM, ENAW, JIS Standard.

Aluminum Circles Packing

1.Plastic cloth with drying agent inside;

2.Pearl Wool ;

3.Wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film.

Introduction of our company

Our company is one of the largest aluminum cookware producer in China, and we have produced aluminium circles over 20years, our aluminum circles could be good quality for cookware deep drawing and spinning dawing usage.

Also we are the professional Aluminium Strip manufacturer and Aluminum Circles manufacturers,mainly supply Aluminium Coil,Aluminum Circles,Aluminium discs,Aluminum Sheet,Aluminum Strip, Household Aluminum Foil,Aluminum Foil for Pharmaceutical Packaging,Aluminum Foil Tape,Aluminum Foil for Air Conditioner,Aluminum Foil for Container etc. series of aluminum products, sincerely welcome everyone to visit.

- Q: How do you prevent galvanic corrosion when combining aluminum profiles with concrete or masonry?

- To prevent galvanic corrosion when combining aluminum profiles with concrete or masonry, there are a few steps that can be taken: 1. Use appropriate materials: Select aluminum profiles that are specifically designed for use in contact with concrete or masonry. These profiles are often coated or treated to provide protection against corrosion. 2. Insulate the aluminum profiles: Apply an insulating barrier between the aluminum profiles and the concrete or masonry surfaces. This can be achieved by using non-conductive materials such as gaskets, rubber pads, or coatings. 3. Avoid direct contact: Whenever possible, try to minimize direct contact between the aluminum profiles and the concrete or masonry. This can be accomplished by using spacers or other forms of separation to create a gap between the two materials. 4. Proper installation: Ensure that the aluminum profiles are installed correctly, following the manufacturer's guidelines and recommendations. This includes using appropriate fasteners and techniques to secure the profiles without compromising the insulation or protective measures. 5. Regular maintenance: Regularly inspect the aluminum profiles and the surrounding concrete or masonry for signs of corrosion or damage. Any issues should be addressed promptly to prevent further deterioration. By following these preventive measures, the risk of galvanic corrosion between aluminum profiles and concrete or masonry can be significantly reduced, prolonging the lifespan and performance of the materials involved.

- Q: Are aluminum profiles suitable for modular construction?

- Yes, aluminum profiles are highly suitable for modular construction. They are lightweight, yet strong and durable, making them ideal for creating modular structures. Aluminum profiles are easy to fabricate and can be easily assembled or disassembled, allowing for flexibility in design and construction. Additionally, aluminum is resistant to corrosion, which ensures the longevity of the modular construction.

- Q: The 50 series and the 60 series of aluminum profiles, which one is good?

- respectively60 of the cross section is larger than 50 1cm, much stronger. The glass gap that can be installed is also larger

- Q: The original aluminum is silver, but now the market has black, yellow and green, aluminum radiator, radiator is the color what are formed by oxidation of different colors, what are the benefits of it, are used in the above types of products?

- As for the coating and metal coating materials processing as the first surface degreasing and coarsening process, then spraying or cathodic electrophoresis mode is used in aluminum surface with a layer of film, choose different properties and color of paint can make the aluminum surface to obtain the corresponding protection performance.

- Q: This question asks for an explanation of various methods used to manufacture aluminum profiles, which are long, extruded shapes made from aluminum.

- <p>Aluminum profiles are manufactured using several processes, primarily extrusion, but also including casting, rolling, and machining. Extrusion is the most common method, where aluminum is heated and forced through a die to create a desired shape. Casting involves pouring molten aluminum into molds to form specific profiles. Rolling is used to produce flat sheets or plates, which can then be further processed. Machining involves cutting and shaping aluminum using tools like lathes and mills. Other processes include forging, which deforms aluminum under high pressure, and powder metallurgy, where aluminum powder is compacted and sintered into a solid profile. Each process has its advantages and is chosen based on the desired profile shape, strength, and application.</p>

- Q: This question asks for a comparison between aluminum profiles and other materials used in constructing frames, focusing on their characteristics and performance.

- <p>Aluminum profiles are favored for building frames due to their high strength-to-weight ratio, making them lightweight yet durable. They offer excellent corrosion resistance, which is superior to materials like steel, which can rust. Aluminum profiles are also easy to machine and form, allowing for complex designs. Compared to wood, they are more resistant to weathering and pests. However, they may not have the same aesthetic appeal as wood or the thermal insulation properties of some plastics. Overall, aluminum profiles are a strong choice for structural integrity and longevity in frame construction.</p>

- Q: What are the bending capabilities of aluminum profiles?

- Due to their inherent properties, aluminum profiles possess exceptional bending capabilities. Aluminum, being a highly malleable metal, can effortlessly assume various shapes without fracturing or breaking, making it an ideal choice for applications that necessitate complex bending or curving. The bending capabilities of aluminum profiles are predominantly influenced by the alloy employed and the specific shape or design being bent. Certain aluminum alloys, such as 6061 or 6063, are commonly utilized for extruded profiles due to their excellent bending properties. These alloys strike a good balance between strength and formability, making them well-suited for bending applications. To bend aluminum profiles, specialized machinery, like a bending machine or a press brake, is typically employed. The profile is meticulously positioned and clamped before pressure is applied to achieve the desired shape. The process can involve multiple passes to accomplish tight or gradual bends. Aluminum profiles can be bent to various angles, ranging from sharp bends to gentle curves, contingent upon the requirements of the application. The bending radius, denoting the minimum radius at which the profile can be bent without causing deformation, is dependent on the profile's thickness, alloy, and temper. Thinner profiles generally possess smaller bending radii compared to thicker ones. It is crucial to note that excessive bending or surpassing the material's capabilities can result in cracking or permanent deformation. Consequently, it is imperative to consider the specific bending requirements and seek guidance from experts or manufacturers to ensure adherence to proper bending techniques and limitations. In conclusion, aluminum profiles exhibit exceptional bending capabilities, facilitating the creation of intricate and customized shapes. Their versatility and formability have made them a favored option in industries such as construction, automotive, aerospace, and furniture manufacturing.

- Q: Can aluminum profiles be used for exhibition stands or booths?

- Exhibition stands or booths can indeed utilize aluminum profiles. The lightweight and robust characteristics of aluminum make it a favored option for constructing such structures. Its ability to provide structural stability, along with the convenience of transportation and assembly, further adds to its appeal. Aluminum profiles are easily customizable, allowing for their seamless integration into diverse designs and configurations, thereby catering to various exhibition needs. Moreover, aluminum's recyclability aligns with the sustainable practices frequently sought after in the exhibition and event industries. In summary, aluminum profiles present a cost-effective and pragmatic choice for the creation of exhibition stands or booths.

- Q: Are aluminum profiles suitable for outdoor use and can they withstand weathering?

- <p>Yes, aluminum profiles can be used for outdoor applications. They are resistant to corrosion and weathering due to their inherent properties and can be anodized or powder coated for additional protection against the elements. This makes them suitable for a variety of outdoor uses such as construction, furniture, and signage. However, it's important to ensure that the profiles are properly finished and maintained to prolong their lifespan and performance outdoors.</p>

- Q: This question asks about the impact of aluminum profiles on the longevity and strength of a building structure.

- <p>Aluminum profiles significantly enhance the durability of a building due to their high strength-to-weight ratio, excellent resistance to corrosion, and low maintenance requirements. They are lightweight yet strong, making them ideal for load-bearing structures and facades. Corrosion resistance means they withstand harsh weather conditions without rusting, which is common in steel profiles. This durability extends the building's lifespan and reduces the need for frequent repairs or replacements, thereby providing a cost-effective long-term solution. Additionally, aluminum profiles can be easily recycled, contributing to sustainable construction practices.</p>

Send your message to us

High Quality Aluminum H Extrusion Profiles for Kitchenware

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords