Aluminum Profile for Kitchen Cabinet Door Frame and Handles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminum Profile for Kitchen Cabinet Door Frame and Handles Description:

We have more than 10 years experiences on manufacturing kinds of aluminum profiles, such as Aluminum Window & Door profiles, Aluminum tile trim profiles, Aluminum profiles for LED light, Round/Square General profiles, Aluminum heat sink, Aluminum heating insulation profiles, Curtain wall Aluminum profiles, and others Industry profiles.

Our products have exported to all over the world, and we also have a large of market share in Algeria, Angola, Philippine, Guinea, Ghana, South Africa, Nepal, Nigeria, Tanzania, Iraq etc.

Main Features of the Aluminum Profile for Kitchen Cabinet Door Frame and Handles:

1, Strong R&G: help customers finalize the design, strong tool design ability, excellent, pressing and surface treatment technology;

2, Strong quality management: ISO&SGS SYSTEM;

3, 24 hours on-line communication, professional, patient, flexible;

4, High capacity of manufacturing and wide range of products;

5, We can provide secondary manufacturing.

6, High corrosion resistance, high weather resistance and good wear resistance.

7, Alternative surface treatment: Colorful ANODIZE, POWDER COATING, ELECTROPHORESIS & WOODEN GRAIN. Plentiful colors upon your needs.

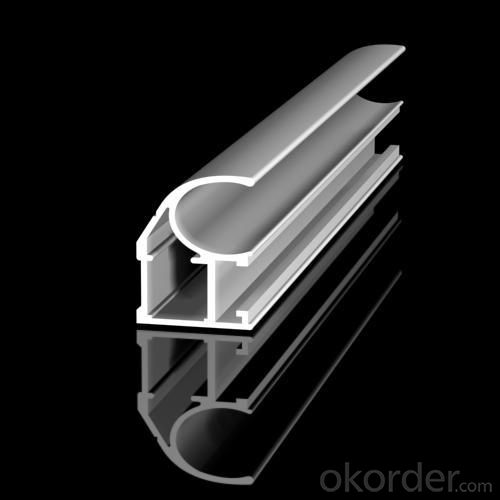

8, Excellent material for smooth and subtle edges, elegant appearance.

9, Strong coated adhesion which is suitable for construction and industrial material.

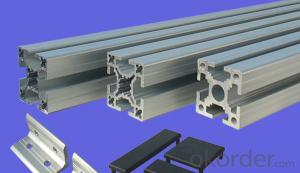

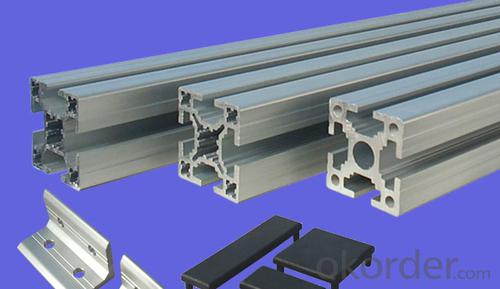

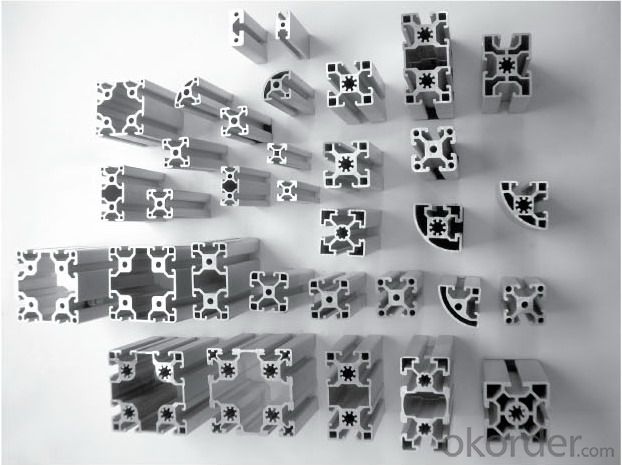

Images of the Aluminum Profile for Kitchen Cabinet Door Frame and Handles:

Aluminum Profile for Kitchen Cabinet Door Frame and Handles Specification:

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

FAQ:

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process.

- Q: How much does aluminum mold need?

- To see the aluminum circle size and large extrusion machine for production, to determine how much the mold fee. Besides, the die fee is returned, provided that how many tons of products are reached.

- Q: A curtain wall predecessors?For example, under the transverse frame section, with 6m specifications, why should the material processing and minus 50mm? Insert plate, plate to cut 100mm head? What is the law?

- The column beam rod in the visual profile factory when surface treatment to hang up or put the spraying profile in oxidation tank, in sections at each end of the play of a hole, so that the hook, in the cutting process, in order to avoid the holes will be seen after the installation and so on when will the cutting part of the section cut ends, this is to cause less 50mm.

- Q: This question asks about the various types of adhesives that can be used for bonding aluminum profiles to the frames of buildings.

- <p>There are several types of adhesives used to attach aluminum profiles to building frames, including epoxy resins, polyurethane adhesives, and silicone sealants. Epoxy resins are known for their high strength and resistance to chemicals and temperature changes. Polyurethane adhesives offer flexibility and are good for bonding different materials. Silicone sealants are used for their weather resistance and flexibility, making them suitable for exterior applications. Each type of adhesive has specific properties that make it suitable for different applications and environmental conditions.</p>

- Q: Are aluminum profiles suitable for use in automotive suspension systems?

- Indeed, automotive suspension systems can benefit from the use of aluminum profiles. Aluminum, being both lightweight and strong, offers numerous advantages in suspension design. To begin with, the lightweight properties of aluminum profiles contribute to reducing the overall weight of the suspension system. This not only improves fuel efficiency but also enhances the vehicle's performance and handling. The decreased weight allows for faster acceleration, improved braking, and enhanced maneuverability. Moreover, aluminum profiles possess an exceptional strength-to-weight ratio, enabling them to withstand high loads and stresses while remaining lightweight. This makes them ideal for handling the dynamic loads experienced by suspension systems, such as bumps, vibrations, and impacts. Aluminum profiles can effectively absorb and distribute these loads, ensuring a smooth and comfortable ride for the vehicle occupants. Additionally, aluminum is highly resistant to corrosion, which is of utmost importance in automotive applications. Given that suspension systems are exposed to various environmental conditions, including moisture, salt, and road debris, the use of aluminum profiles minimizes the risk of corrosion. This, in turn, enhances the durability and longevity of the suspension components. Furthermore, aluminum profiles offer great versatility and can be easily shaped and formed into complex geometries required for suspension system components. This allows for greater design flexibility and optimization of performance. Aluminum profiles can be utilized in the manufacturing of various suspension components, including control arms, knuckles, and subframes. In conclusion, aluminum profiles are unquestionably suitable for use in automotive suspension systems. Their lightweight nature, high strength-to-weight ratio, corrosion resistance, and design flexibility make them an excellent choice for maximizing the performance, efficiency, and durability of suspension systems in vehicles.

- Q: Are aluminum profiles suitable for use in the electronics industry?

- Yes, aluminum profiles are suitable for use in the electronics industry. Aluminum is lightweight, corrosion-resistant, and has excellent thermal conductivity, making it ideal for applications such as heat sinks, enclosures, and frames in electronic devices. Additionally, aluminum profiles can be easily customized and are cost-effective, making them a popular choice in the electronics industry.

- Q: Is it possible to utilize aluminum profiles as a material for flooring?

- <p>Yes, aluminum profiles can be used for flooring, particularly in industrial or commercial settings where durability and resistance to wear are required. They are known for their strength, lightweight, and corrosion resistance, making them suitable for high-traffic areas. Aluminum profiles can be used to create grid systems or as support structures for modular flooring solutions. However, they are not typically used as the direct surface material for flooring due to their hardness and potential for thermal conductivity, which can make them uncomfortable underfoot. Instead, they are often part of a system that supports other flooring materials like tiles or planks.</p>

- Q: How do aluminum profiles perform in terms of thermal conductivity?

- Aluminum profiles exhibit excellent thermal conductivity, allowing them to efficiently transfer heat and manage temperature fluctuations.

- Q: This question asks for a list of various aluminum profiles that are utilized in the construction of building facades and cladding systems.

- <p>Aluminum profiles for facades and cladding systems come in various types, each serving specific purposes in construction. Common types include: 1. <strong>Aluminum Extrusions</strong>: Used for structural support and can be customized for specific design requirements. 2. <strong>Aluminum Channels</strong>: Often used for attaching panels or as a part of the support structure. 3. <strong>Aluminum Angles</strong>: Provide corner support and reinforcement. 4. <strong>Aluminum Flat Bars</strong>: Used for horizontal or vertical support in facade systems. 5. <strong>Aluminum Tubes</strong>: Can be used as a decorative element or for structural reinforcement. 6. <strong>Aluminum Louvers</strong>: Designed for sun shading and ventilation. 7. <strong>Aluminum Panels</strong>: Can be flat or profiled, used for the outer layer of the facade. 8. <strong>Aluminum Trims and Mouldings</strong>: Used for finishing and detailing around windows, doors, and edges. Each type is chosen based on the architectural design, structural requirements, and aesthetic preferences.</p>

- Q: Are aluminum profiles durable?

- Indeed, aluminum profiles possess remarkable durability. Renowned for its exceptional strength-to-weight ratio, aluminum emerges as an optimal selection for numerous applications wherein durability assumes utmost importance. Primarily, aluminum profiles exhibit resistance against corrosion, thereby enabling them to endure exposure to harsh environmental conditions without undergoing deterioration. Moreover, aluminum profiles boast exceptional structural integrity, enabling them to withstand heavy loads and impacts without succumbing to bending or breaking. Consequently, they emerge as highly dependable and enduring, rendering them a favored choice across industries including construction, automotive, aerospace, and numerous others.

- Q: Can aluminum profiles be used in railway and transportation infrastructure?

- Yes, aluminum profiles can be used in railway and transportation infrastructure. Aluminum is a lightweight and durable material that offers several advantages in these applications. One of the main benefits of using aluminum profiles in railway and transportation infrastructure is their low weight. Aluminum is significantly lighter than other materials like steel, making it easier to transport and install. This weight reduction can also lead to energy savings, as less fuel is required to move the infrastructure elements. Additionally, aluminum profiles have a high strength-to-weight ratio, meaning they can withstand heavy loads while still being relatively lightweight. This makes them suitable for various structural applications, such as supporting overhead power lines, constructing platforms, and forming the framework for bridges and tunnels. Aluminum also has excellent corrosion resistance, which is crucial in railway and transportation infrastructure exposed to harsh weather conditions and environmental elements. Aluminum profiles can withstand moisture, UV rays, and other corrosive agents, reducing maintenance requirements and increasing the lifespan of the infrastructure. Moreover, aluminum profiles can be easily fabricated and customized to meet specific design requirements. They can be extruded into various shapes and sizes, allowing for flexibility in design and construction. Aluminum profiles can also be easily joined together using different methods, such as welding or fastening, providing ease of assembly and disassembly if needed. In conclusion, aluminum profiles can indeed be used in railway and transportation infrastructure. Their lightweight, high strength, corrosion resistance, and versatility make them an excellent choice for various structural and functional applications in these sectors.

Send your message to us

Aluminum Profile for Kitchen Cabinet Door Frame and Handles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords