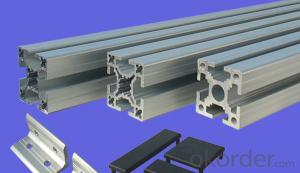

Top Grade Kitchen Cupboard Aluminum Profiles India

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft, durable, lightweight, ductileand malleablemetalwith appearance ranging from silvery to dull gray, depending on the surfaceroughness. It is nonmagnetic and does not easily ignite. A fresh film ofaluminium serves as a good reflector (approximately 92%) of visible lightand an excellent reflector (as much as 98%) of medium and far infraredradiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the densityand stiffness of steel. It is easily machined,cast, drawn and extruded.

Features:

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

- Q: Are aluminum profiles suitable for use in automotive suspension systems?

- Yes, aluminum profiles are suitable for use in automotive suspension systems. Aluminum is lightweight, yet strong and durable, making it an ideal material for reducing the overall weight of the suspension system. The use of aluminum profiles can improve the handling, fuel efficiency, and performance of the vehicle. Additionally, aluminum profiles offer excellent corrosion resistance, contributing to the longevity of the suspension system.

- Q: Shanghai industrial aluminum profile manufacturers which is better?

- Third: in production of aluminium supplierExplain as follows: in the production of aluminum suppliers, are generally engaged in this industry for more than 10 years, and their users have very rich experience, have a good understanding and knowledge of the quality and performance of products, suitable for the requirement of the customers will recommend price is a good product, choose a convenient and practical accessories.

- Q: How much is the 60 series aluminum frame bridge standard size, how much is the size of the fan

- 60 series of insulating aluminum window size 60x53.5, window size 67.8x68.6.Distinguish the bridge aluminum, such as 55 series, refers to the broken bridge aluminum window frame width is 5.5 cm, and the aluminum 70 series refers to the broken bridge aluminum window frame width of 7 cm, the main difference between them lies above the insulation wall thickness and the width of aluminum. The aluminum 55 series and 60 series of wall thickness is the national standard 1.4MM, aluminum doors and windows insulation insulation than 60 series 55 series terms 0.5 cm, aluminum wall thickness, the difference is not, but the 55 series and 70 series of different, one is the 70 series of more than 55 of the width to 1.5 cm wide, the second is the aluminum 70 series aluminum wall thickness is 1.8MM, far better than the national standard.Hollow glass aluminum doors and windows 55 models for 5+12A+5 glass, the middle interval is 12, while the hollow glass interval of 70 series aluminum doors and windows 22, so the aluminum 70 series 55 series of aluminum than sound better. The use of aluminum in the family model 55 is enough, this is the standard engineering materials, which is the most common type of use, if the noise requirements higher, it can be considered by the German red card 70 series of ten sealing design, especially along the street district is relatively high requirements on the sound. Is the best choice.

- Q: 80 series insulation aluminum broken bridge 1.4 thick, one square kilogram, how many kilograms aluminum material?

- Each brand of profiles, aluminum weight is not the same, but within the unit area is about 8 kilograms, little difference

- Q: Ask Master: at present domestic industry deep aluminum extrusion production line of domestic manufacturers are also many, but the price is still the production line and abroad have obvious difference, then foreign production lines in what ways do better? Thank you

- On the equipment, the extrusion line of Germany and Japan is more automatic, and the on-line quenching is the setting program for automatic operation.

- Q: Can aluminum profiles be used in cleanroom environments?

- Yes, aluminum profiles can be used in cleanroom environments. Aluminum is a lightweight and versatile material that possesses many desirable qualities for cleanroom applications. It is non-corrosive, non-magnetic, and has a high strength-to-weight ratio, making it suitable for constructing cleanroom structures such as walls, partitions, and equipment racks. Aluminum profiles can be easily assembled and disassembled, allowing for flexible cleanroom configurations and future modifications. They can also be integrated with other materials like glass, acrylic, or stainless steel to meet specific cleanroom requirements. Additionally, aluminum profiles can be anodized or coated to enhance their cleanliness and resistance to contamination. Anodization provides a protective layer on the surface of the aluminum, making it more resistant to scratches and wear. Coatings such as epoxy or powder coatings can further improve the durability and cleanliness of the profiles. Overall, aluminum profiles offer numerous advantages for cleanroom applications, including their lightweight nature, strength, corrosion resistance, and flexibility in design.

- Q: What are the potential hazards or risks associated with the use of aluminum profiles in construction projects?

- <p>Safety concerns related to using aluminum profiles in construction include potential corrosion due to exposure to harsh weather conditions, risk of electrical conductivity which may lead to electrocution hazards, and the possibility of thermal expansion and contraction causing structural instability. Additionally, improper installation can lead to structural failure, and the lightweight nature of aluminum may not provide sufficient strength in load-bearing applications. It's crucial to ensure proper design, quality materials, and adherence to safety standards to mitigate these risks.</p>

- Q: What are the different types of corner connectors used with aluminum profiles?

- Aluminum profiles commonly utilize several types of corner connectors for joining. These connectors facilitate the creation of diverse structures like frames, enclosures, and shelving units. One prevalent corner connector is the 90-degree angle bracket. It possesses a right angle shape with holes on each side to accommodate screws or bolts for fastening the profiles together. The 90-degree angle bracket is adaptable and suitable for various applications. Another corner connector is the 45-degree angle bracket, similar to the 90-degree angle bracket but designed for a 45-degree angle joint between profiles. It finds use in applications requiring slanted or angled structures. T-slot corner connectors are also popular. They have a T-shaped slot for easy insertion of profiles. These connectors are ideal for applications that prioritize adjustability and flexibility, allowing for effortless repositioning and modification of the structure. Some corner connectors are specifically designed for particular profile types, such as the end cap connector. This connector caps off the profile's end, providing a polished appearance and protection against damage. Furthermore, various other corner connectors exist, including corner gussets, angle plates, and corner brackets. Each connector type offers unique features and advantages, catering to different applications and requirements. In summary, the assortment of corner connectors available for aluminum profiles offers a wide range of options for joining and assembling structures. These connectors provide strength, stability, and versatility, making them indispensable components in aluminum profile-based construction projects.

- Q: What are the noise insulation properties of aluminum profiles?

- Aluminum profiles have good noise insulation properties due to their density and ability to dampen sound vibrations. They can effectively reduce external noise and provide a quieter indoor environment.

- Q: What are the different types of protective coatings for aluminum profiles?

- There exists a variety of protective coatings for aluminum profiles that serve to enhance their durability and lifespan, as well as add aesthetic appeal. Some common types include: 1. Anodizing: This popular and widely used coating involves an electrochemical process that generates a thin, transparent layer of aluminum oxide on the metal's surface. It provides exceptional corrosion resistance and can be customized with various dye colors. 2. Powder Coating: In this dry finishing process, an electrostatically charged powder is applied onto the aluminum surface, then heated to create a durable and protective coating. Powder coating offers excellent resistance to impact, chemicals, and corrosion, while also providing a uniform and attractive finish. 3. Paint Coating: Aluminum profiles often utilize paint coatings, particularly in applications where aesthetics are crucial. These coatings can be applied through spraying, brushing, or dipping methods, offering protection against corrosion, UV rays, and other environmental factors. They also offer a wide range of color options. 4. E-Coating: Also known as electrocoating or electrophoretic deposition, this immersion-based process involves submerging the aluminum profiles in a water-based paint solution and applying an electric current. This results in a uniform and protective coating, often used as a primer before applying other coatings. E-coating excels in corrosion resistance. 5. Clear Coating: Transparent protective layers, such as clear lacquers or clear anodizing, are frequently employed to preserve the natural appearance of aluminum profiles while shielding them against corrosion and environmental factors. Choosing the appropriate protective coating for your aluminum profiles necessitates considering specific requirements and the intended application. Factors such as durability, corrosion resistance, aesthetics, and cost should be taken into account to ensure the optimal choice for your particular needs.

Send your message to us

Top Grade Kitchen Cupboard Aluminum Profiles India

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords