Top 3 EPDM Rubber Roofing Waterproof Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Waterproof Membrane

Introduction for EPDM Waterproof Membrane

This waterproof coiled material is of high elasticity with best performance among high polymer waterproof coiled material in the world.It is also the most typical one in the world.Waterproof coiled material made of ternary ethylene-propylene rubber of ‘CHEN SHENG’ brand is produced with the use of the most advanced continuous extrusion and vulcanization technology and related equipments which are specially designed for production of such product.It is good in compactness,without bubble and performance difference in length and breadth,performances reach or exceed the demands of GB18173.1-2012 standard.

Characteristics for EPDM Waterproof Membrane

1 Excellent physical and mechanical performance

2 High tearing resistance

3 Good deformation adaptability

4 High puncture resistance

5 High aging resistance

6 High UV resistance

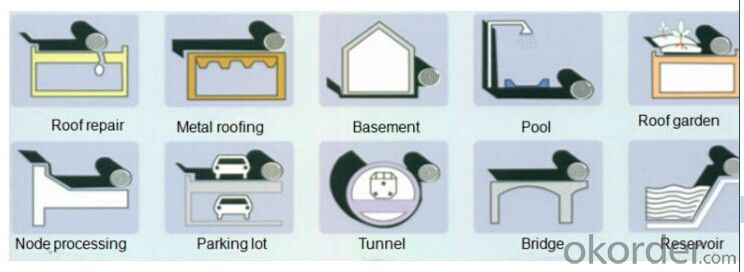

Application for EPDM Waterproof Membrane

1) Roofs, Basement, Toilet

2) Industrial and civil building waterproofing

3) Geo-synthetic liner for swimming pool, channels, irrigation system

4) Especially suit for projects with high requirements in durability, anti-corrosion and deformation

Specification for EPDM Waterproof Membrane

Item | Thick(mm) | Width | Length(m) | Color |

Spe | 1.0—2.0 | 1.2m/2m/3m/4m | 20 | Black |

Deviation | -1 +15 | --1 | Multicolor |

Technical Sheet for EPDM Waterproof Membrane

EPDM Waterproof Membrane ASTM Standard : D-7465 | ||||

Property | Test Method | Units | Mininum ASTM | |

D-7465 | ||||

Sl | Eng | |||

Specific Gravity | ASTM D-792 | gm/cc | 1.1 | 1.1 |

Unit Weight | ASTM D-751 | kg/m2 | 1.3 | 0.27 |

Thickness Type 1 | ASTM D-412 | mm(in) | 1.02 | 0.04 |

Tensile Strength. Die C | ASTM D-412 | Mpa(psi) | 9 | 1305 |

Ultimate Elongation,Die C | ASTM D-412 | % | 300 | 300 |

Tear Resistance,Die C | ASTM D-624 | Kn/m(lbf/in) | 26.27 | 150 |

Puncture Resistance | ASTM D-4833 | N(lbs) | 133 | 30 |

Shore A Durometer | ASTM D-2240 | 65-10 | 65-10 | |

Ozone Resistance | ASTM D-1149 | No Crack | No Crack | |

Multiaxial Elongation | ASTM D-5617 | % | 100 | 100 |

Heat Aging 28 days at 240 degrees | ASTM D-573 | |||

Tensile Strength, Die C | ASTM D-412 | MPa(psi) | 8.3 | 1205 |

Ultimate elongation, Die C | ASTM D-412 | % | 200 | 200 |

Tear Resistance, Die C | ASTM-624 | Kn/m(lbf/in) | 21.9 | 125 |

Accelerated Aging Xenon Arc | ASTM G-155/G-151 | Pass | Pass | |

Brittleness Point | ASTM D-2137 | -45 °C | -49 °C F | |

Water Absorption | ASTM D-471 | % | +8,-2 | +8,-2 |

Water Vapor Permeability, max | ASTM E-96 | Permils | 2.0 | 2.0 |

Linear Dimensional Change,max | ASTM-D-1204 | % | +/-1.0 | +/-1.0 |

Chronic Toxicity Screening | EPA/600/4-89/001 | Method 1000.0 | Pass | Pass |

FAQ:

Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q: Can a waterproofing membrane be used in planter boxes or raised beds?

- Yes, a waterproofing membrane can be used in planter boxes or raised beds to prevent water leakage and protect the surrounding structures. A waterproofing membrane is typically made of materials such as rubber, PVC, or polyethylene, which create a barrier between the soil and the surrounding area. This barrier helps retain moisture within the planter box or raised bed, preventing water from seeping into the ground and potentially causing damage to the foundation or nearby structures. Additionally, a waterproofing membrane can also prevent the leaching of chemicals or fertilizers from the soil, improving the overall quality of the planting environment. Nevertheless, it is important to ensure proper drainage in planter boxes or raised beds to prevent waterlogging and root rot.

- Q: Floor tiles on the terrace leak, can be directly on the brick shop SBS coil and then cast the cement?

- 2, sealed platform color steel roof waterproof, terrace top waterproof is a comprehensive topic, and now a lot of backstage behind the shops are using SBS linoleum method, but do not feel the most suitable for the most appropriate method. The new bridge doors and windows cover waterproof waterproof composite process, according to the top of the terrace structure, to determine the final waterproof construction process. Many of the processes are: slotted, filled, waterproof side, neutral weather resistant structural seal, SBS linoleum, new water does not leak waterproof material, usually a variety of waterproofing process, because any kind of material A little bit and the shortcomings, so the combination of construction, will make up each other, and ultimately achieve the waterproof effect, so called double waterproof.

- Q: Can a waterproofing membrane be used for stadiums and sports arenas?

- A waterproofing membrane is suitable for stadiums and sports arenas, as they are subjected to different weather conditions and are susceptible to water damage. These large structures can be effectively protected against water infiltration by applying waterproofing membranes to various areas such as the roof, walls, and foundation. This not only maintains the building's integrity and extends its lifespan but also prevents expensive repairs caused by water damage. Moreover, these membranes offer insulation and energy-saving advantages, thereby improving the overall performance of the stadium or sports arena.

- Q: Can a waterproofing membrane be used on asphalt surfaces?

- Yes, a waterproofing membrane can be used on asphalt surfaces. Waterproofing membranes are commonly used in construction and are designed to provide a protective barrier against water infiltration. They are versatile and can be applied to various surfaces, including asphalt. Applying a waterproofing membrane on an asphalt surface can help prevent water damage, increase the longevity of the surface, and protect the underlying structures. It is important to ensure that the waterproofing membrane used is compatible with asphalt and that proper installation techniques are followed to achieve optimal results.

- Q: Can a waterproofing membrane be used on precast gypsum surfaces?

- Yes, a waterproofing membrane can be used on precast gypsum surfaces. This membrane acts as a barrier to prevent water penetration and can be applied to protect the gypsum surface from moisture damage.

- Q: Can a waterproofing membrane be used for a bridge?

- Yes, a waterproofing membrane can be used for a bridge. Waterproofing membranes are commonly used in bridge construction to prevent water infiltration and protect the structure from deteriorating due to moisture. These membranes act as a barrier against water and can significantly extend the lifespan of bridges by preventing corrosion and structural damage caused by water exposure.

- Q: How is the water level rated and how many grades are used?

- 2, the roof waterproof level 2: Applications: important buildings and high-rise buildings; Waterproof layer of reasonable use of life: 15 years; Waterproof layer selection of materials: should choose high polymer modified asphalt waterproofing membrane, synthetic polymer waterproofing membrane, metal sheet, synthetic polymer waterproof coating, high polymer modified asphalt waterproof coating, fine stone concrete, flat tile, linoleum Tile and other materials; Fortification requirements: two waterproof fortification.

- Q: Can a waterproofing membrane be used for railways or train stations?

- Yes, a waterproofing membrane can definitely be used for railways or train stations. Waterproofing membranes are commonly used in various construction projects to protect structures from water damage and ensure their longevity. In the case of railways and train stations, where there is constant exposure to weather elements and potential water infiltration, a waterproofing membrane can play a crucial role in preventing water ingress into the infrastructure. Waterproofing membranes are typically applied to different areas of the railway or train station, such as the underground tunnels, platforms, parking areas, and even the roofs. These membranes are designed to create a barrier against water and moisture, preventing them from seeping into the structure and causing damage. By preventing water infiltration, a waterproofing membrane helps to maintain the structural integrity of the railway or train station and extend its lifespan. In addition to protecting against water, waterproofing membranes also provide other benefits such as preventing the growth of mold and mildew, improving energy efficiency by reducing heat loss, and enhancing the overall durability of the structure. They are available in various types, including liquid-applied membranes, sheet membranes, and cementitious coatings, allowing for versatile application depending on the specific needs and requirements of the railway or train station project. Overall, the use of a waterproofing membrane in railways and train stations is highly recommended to ensure the long-term performance and maintenance of these critical infrastructures.

- Q: Can a waterproofing membrane be used on tunnels with water drainage systems?

- Yes, a waterproofing membrane can be used on tunnels with water drainage systems. The membrane acts as a barrier, preventing water from penetrating the tunnel structure and directing it towards the drainage system for proper disposal. This helps to ensure the integrity and longevity of the tunnel while effectively managing water flow.

- Q: Can a waterproofing membrane be used for a planter box wall?

- Indeed, a planter box wall can benefit from the application of a waterproofing membrane. This specialized membrane is specifically designed to create a barrier against water infiltration, making it an excellent choice for a planter box wall where moisture is present. By employing a waterproofing membrane on the interior surface of the planter box, one can effectively safeguard the wall against moisture-related harm and prevent water from seeping into the adjacent soil. This proactive measure not only prolongs the lifespan of the planter box but also mitigates the risk of water damage to the surrounding area. However, it is imperative to ensure that the chosen waterproofing membrane is compatible with the materials utilized in the construction of the planter box and to adhere to the manufacturer's instructions for proper installation.

Send your message to us

Top 3 EPDM Rubber Roofing Waterproof Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords