No1 EPDM Rubber Roofing Waterproof Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Waterproof Membrane

Introduction for EPDM Waterproof Membrane

This waterproof coiled material is of high elasticity with best performance among high polymer waterproof coiled material in the world.It is also the most typical one in the world.Waterproof coiled material made of ternary ethylene-propylene rubber of ‘CHEN SHENG’ brand is produced with the use of the most advanced continuous extrusion and vulcanization technology and related equipments which are specially designed for production of such product.It is good in compactness,without bubble and performance difference in length and breadth,performances reach or exceed the demands of GB18173.1-2012 standard.

Characteristics for EPDM Waterproof Membrane

1.the excellent anti-aging, in the long term light, humidity, cold use of the natural environment, small changes in physical properties, used in the temperature. From -50 degree Celsius to +150degree Celsious.

2.with outstanding ozone resistance, resistance to ultraviolet and atmospheric corrosion of many chemical corrosive substances.

3. high tensile strength, high elongation, high flexibility, capable of sustaining a puncture of hard material, good anti-crack and deformation and give full play to extend the performance, playing the role of waterproofing.

4.long lifetime, high durability can achieve more than 25 years.

5.the cold construction operation, no environment pollution and simple operation.

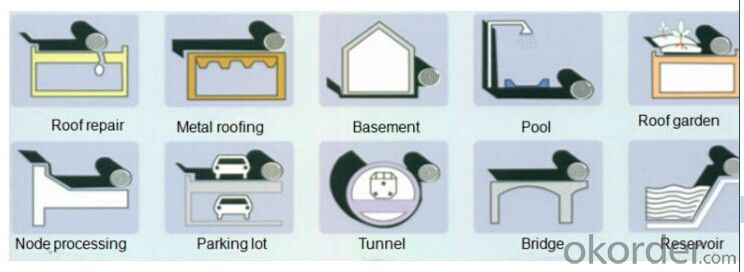

Application for EPDM Waterproof Membrane

1) Roofs, Basement, Toilet

2) Industrial and civil building waterproofing

3) Geo-synthetic liner for swimming pool, channels, irrigation system

4) Especially suit for projects with high requirements in durability, anti-corrosion and deformation

Specification for EPDM Waterproof Membrane

Item | Thick(mm) | Width | Length(m) | Color |

Spe | 1.0—2.0 | 1.2m/2m/3m/4m | 20 | Black |

Deviation | -1 +15 | --1 | Multicolor |

Technical Sheet for EPDM Waterproof Membrane

EPDM Waterproof Membrane ASTM Standard : D-7465 | ||||

Property | Test Method | Units | Mininum ASTM | |

D-7465 | ||||

Sl | Eng | |||

Specific Gravity | ASTM D-792 | gm/cc | 1.1 | 1.1 |

Unit Weight | ASTM D-751 | kg/m2 | 1.3 | 0.27 |

Thickness Type 1 | ASTM D-412 | mm(in) | 1.02 | 0.04 |

Tensile Strength. Die C | ASTM D-412 | Mpa(psi) | 9 | 1305 |

Ultimate Elongation,Die C | ASTM D-412 | % | 300 | 300 |

Tear Resistance,Die C | ASTM D-624 | Kn/m(lbf/in) | 26.27 | 150 |

Puncture Resistance | ASTM D-4833 | N(lbs) | 133 | 30 |

Shore A Durometer | ASTM D-2240 | 65-10 | 65-10 | |

Ozone Resistance | ASTM D-1149 | No Crack | No Crack | |

Multiaxial Elongation | ASTM D-5617 | % | 100 | 100 |

Heat Aging 28 days at 240 degrees | ASTM D-573 | |||

Tensile Strength, Die C | ASTM D-412 | MPa(psi) | 8.3 | 1205 |

Ultimate elongation, Die C | ASTM D-412 | % | 200 | 200 |

Tear Resistance, Die C | ASTM-624 | Kn/m(lbf/in) | 21.9 | 125 |

Accelerated Aging Xenon Arc | ASTM G-155/G-151 | Pass | Pass | |

Brittleness Point | ASTM D-2137 | -45 °C | -49 °C F | |

Water Absorption | ASTM D-471 | % | +8,-2 | +8,-2 |

Water Vapor Permeability, max | ASTM E-96 | Permils | 2.0 | 2.0 |

Linear Dimensional Change,max | ASTM-D-1204 | % | +/-1.0 | +/-1.0 |

Chronic Toxicity Screening | EPA/600/4-89/001 | Method 1000.0 | Pass | Pass |

Vulcanization Production Line

Weldable Production line

FAQ:

Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q: Can waterproofing membranes be used on utility tunnels?

- Yes, waterproofing membranes can be used on utility tunnels. Utility tunnels are often subjected to moisture and water infiltration, and using waterproofing membranes can help prevent water damage and ensure the longevity of the tunnel structure. Waterproofing membranes are designed to create a barrier between the structure and the surrounding environment, effectively preventing water from seeping into the tunnel. These membranes are typically made from materials such as bitumen or synthetic polymers, which are highly resistant to water penetration. By applying these membranes to the walls, floors, and ceilings of utility tunnels, they can effectively protect the structure from water damage, including leaks, cracks, and deterioration. Additionally, waterproofing membranes also help to maintain the integrity of utility tunnels by preventing the ingress of harmful substances such as chemicals or pollutants. Overall, using waterproofing membranes on utility tunnels is an effective method to ensure their durability and functionality in the long term.

- Q: What is the meaning of the node and the additional layer in the construction of the membrane waterproofing layer?

- Additional layer refers to the large area before the construction of the node parts of the pre-treatment, need to strengthen the protection of these weak links in advance, generally do more than a layer of coil.

- Q: Can a waterproofing membrane be used on bridges?

- Yes, a waterproofing membrane can be used on bridges. Waterproofing membranes are commonly used in bridge construction and rehabilitation projects to protect the bridge deck from water infiltration. These membranes are designed to provide a seamless and durable barrier against water, preventing moisture from reaching the underlying bridge structure. By applying a waterproofing membrane on the bridge deck, it helps to extend the lifespan of the bridge by minimizing the damage caused by moisture and preventing corrosion of the reinforcement steel. Additionally, waterproofing membranes can also help to reduce the potential for freeze-thaw damage, cracking, and deterioration of the bridge deck. Overall, the use of a waterproofing membrane on bridges is an effective solution to ensure the long-term durability and structural integrity of the bridge.

- Q: Can a waterproofing membrane be used in areas with extreme temperatures?

- Yes, a waterproofing membrane can be used in areas with extreme temperatures. Waterproofing membranes are designed to withstand a wide range of temperatures and are often used in both hot and cold climates. They are engineered to be flexible and durable, allowing them to effectively protect against water intrusion and withstand temperature fluctuations without losing their effectiveness.

- Q: How does a waterproofing membrane handle exposure to chemicals?

- Different types of waterproofing membranes have varying levels of resistance to chemicals. Some membranes are specifically designed to withstand exposure to chemicals, while others may not be as resistant. Typically, a waterproofing membrane that is specifically formulated to handle chemicals will have certain properties that make it more resistant. These properties may include a thicker material, increased flexibility, and additives that enhance chemical resistance. When a waterproofing membrane is exposed to chemicals, it should ideally be able to resist degradation, maintain its physical properties, and continue to effectively repel water. However, it is important to consider that certain chemicals may still have a negative effect on the membrane, especially if they are highly corrosive or reactive. To ensure the best performance when dealing with chemical exposure, it is recommended to choose a waterproofing membrane that is specifically designed to handle the types of chemicals it will encounter. It is also important to follow the manufacturer's guidelines for installation and maintenance to maximize the membrane's chemical resistance and overall lifespan. Regular inspections and maintenance are essential for identifying any signs of chemical damage or degradation on the waterproofing membrane. In cases where significant chemical exposure is expected, additional protective measures such as chemical-resistant coatings or overlays may be necessary to provide an extra layer of defense. In conclusion, the ability of a waterproofing membrane to withstand exposure to chemicals depends on its specific formulation and design. By selecting a membrane with appropriate chemical resistance properties and practicing proper maintenance, its longevity and effectiveness in chemical environments can be ensured.

- Q: SBS Shale Waterproof Coil

- SBS modified asphalt waterproofing membrane, this coil has a good high temperature performance, can be -25 to +100 ℃ temperature range of use, a higher flexibility and fatigue resistance, and up to 1500% Elongation and strong puncture resistance, tear resistance. Suitable for cold areas, as well as deformation and vibration of large industrial and civil buildings waterproofing works.

- Q: What kind of waterproofing membrane, waterproofing membrane is how to classify their respective advantages?

- EPDM waterproofing membrane: Dura Pruff Germany imports, can be welded EPDM rubber waterproofing membrane, Wendi welding up to 470 ℃, can still be used after welding, support preform, material warranty 20 years And the welding tape is homogeneous with the material.

- Q: Can a waterproofing membrane be used in combination with insulation materials?

- Yes, a waterproofing membrane can be used in combination with insulation materials. In fact, it is often recommended to use a waterproofing membrane in conjunction with insulation to provide enhanced protection against water damage and moisture intrusion. The waterproofing membrane acts as a barrier, preventing water from penetrating the building envelope, while the insulation materials help to regulate temperature and improve energy efficiency. By combining these two elements, you can create a more durable and efficient building envelope system. However, it is important to ensure that the chosen waterproofing membrane is compatible with the insulation materials being used, and that proper installation techniques are followed to ensure a tight seal and optimal performance.

- Q: What is the use of waterproof membrane?

- As we all know, the quality of waterproofing membrane is good or bad, the use of appropriate, a direct impact on the quality of waterproofing works, the life of the building also has a direct impact.

- Q: Can a waterproofing membrane be used on tunnels with lighting systems?

- Yes, a waterproofing membrane can be used on tunnels with lighting systems. The membrane can effectively protect the tunnel structure from water infiltration while allowing the lighting system to function properly.

Send your message to us

No1 EPDM Rubber Roofing Waterproof Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords