Top 3 EPDM Rubber Roofing Waterproof Membrane More Than 10Years

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Waterproof Membrane

Introduction for EPDM Waterproof Membrane

This waterproof coiled material is of high elasticity with best performance among high polymer waterproof coiled material in the world.It is also the most typical one in the world.Waterproof coiled material made of ternary ethylene-propylene rubber of ‘CHEN SHENG’ brand is produced with the use of the most advanced continuous extrusion and vulcanization technology and related equipments which are specially designed for production of such product.It is good in compactness,without bubble and performance difference in length and breadth,performances reach or exceed the demands of GB18173.1-2012 standard.

Characteristics for EPDM Waterproof Membrane

1.Excellent anti-aging performance, service life can reach 50 years;

2.High elongation, high tensile strength, heat treatment size change small;

3.Plant root penetration resistance is good

4.Good low temperature flexibility

5.Application is convenient, overlapping is firm and reliable, no environmental pollution;

6. Resistance to chemical corrosion, can be applied to special places;

7.Maintenance is convenient, the cost is low

Specifications for EPDM Waterproof Membrane

Type | EPDM Waterproof Membrane | ||

Material | EPDM Rubber | ||

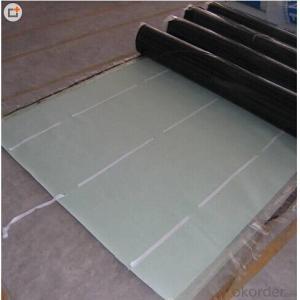

Thickness | 1.2mm | 1.5mm | 2.0mm |

Weight(kg/m2) | 1.54-1.58 | 1.79-1.83 | 2.25-2.29 |

Size | 1.2m(width) * 20m(length)/roll | ||

Type | Vulcanized & Weldable | ||

Pattern | Non-reinforced(homogeneous) | ||

Packing | 24sqm/roll, with plastic bag | ||

Color | Black | ||

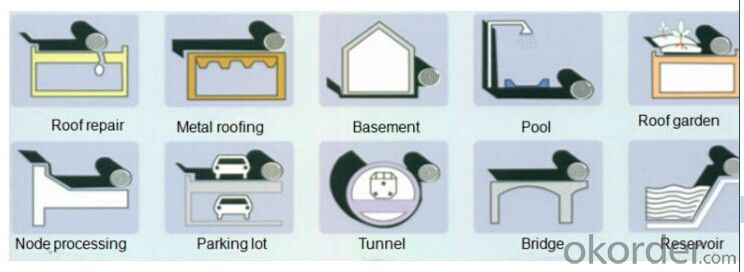

Application | Roof, basement, pond, Lake, steel structure roof, swimming pool, underground, tunnel, etc | ||

Application for EPDM Waterproof Membrane

1) Roofs, Basement, Toilet

2) Industrial and civil building waterproofing

3) Geo-synthetic liner for swimming pool, channels, irrigation system

4) Especially suit for projects with high requirements in durability, anti-corrosion and deformation

Technical Sheet for EPDM Waterproof Membrane

NO | Item | unit | Technical requirement | ||

1 | Tolerance on size | Thickness | % | ±10 | |

Width | % | ±1 | |||

length | % | Does not allow negative | |||

2 | Fracture tensile strength (normal temperature ) | Mpa | ≥7.5 | ||

Fracture tensile strength(60 degree) | Mpa | ≥2.3 | |||

3 | Breaking elongation,(normal temperature ) | % | ≥450 | ||

Breaking elongation,(zero 20 degree) | % | ≥200 | |||

4 | Tearing resistance | KN/m | ≥25 | ||

5 | impermeability | * | 0.3Mpa impermeable | ||

6 | Bending at low temperature | °C | ≤-40 | ||

7 | Elongation and contraction volume at heating | Elongation | mm | ≤2 | |

contraction | mm | ≤4 | |||

8 | Hot air aging 80°CX168h | Fracture strength retention | % | ≥80 | |

Rate of elongation at break | % | ≥80 | |||

9 | Alkaline (saturated Ca(OH)2 solution normal Temperature x2 168h ) | Fracture strength retention | % | ≥80 | |

Rate of elongation at break | % | ≥80 | |||

10 | Ozone aging (40 degree by 168 hours ) | Elongation 40% , 500x10-2 | * | No Crack | |

11 | Phytotron aging | Fracture strength retention | % | ≥80 | |

Rate of elongation at break | % | ≥70 | |||

FAQ:

Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q: Can a waterproofing membrane be used for sewage treatment plants and wastewater facilities?

- Yes, a waterproofing membrane can be used for sewage treatment plants and wastewater facilities. These membranes are designed to prevent water penetration and are commonly used to protect structures from water damage. In sewage treatment plants and wastewater facilities, where constant exposure to water and moisture is present, a waterproofing membrane can help maintain the integrity of the structures and prevent any leaks or water seepage.

- Q: Is a waterproofing membrane necessary for all types of construction?

- A waterproofing membrane is not necessary for all types of construction, but it is highly recommended for certain types of projects. The need for a waterproofing membrane depends on several factors, including the location and purpose of the construction, the materials used, and the potential exposure to water or moisture. In general, a waterproofing membrane is essential in areas where water intrusion is a common occurrence, such as basements, foundation walls, roofs, bathrooms, and areas with high humidity levels. These areas are susceptible to water damage, which can lead to structural issues, mold growth, and deterioration of building materials. Waterproofing membranes provide an effective barrier against water penetration, preventing any potential damage caused by moisture. They are typically made from materials like asphalt, rubber, or polyethylene, and are applied as a thin layer over the surface to create a watertight seal. Additionally, some membranes can also provide insulation benefits, further enhancing the energy efficiency of the construction. While a waterproofing membrane may add to the construction cost, its benefits outweigh the expenses in the long run. It helps to protect the structural integrity of the building, prolong its lifespan, and prevent costly repairs or renovations due to water damage. However, it is important to note that not all construction projects require a waterproofing membrane. For example, buildings located in arid regions or areas with minimal rainfall may not require extensive waterproofing measures. Similarly, certain types of construction, such as open-air structures or temporary installations, may not necessitate a waterproofing membrane. Ultimately, the decision to incorporate a waterproofing membrane into a construction project should be based on a thorough assessment of the specific conditions, risks, and requirements of the project. Consulting with a professional architect or engineer can help determine whether a waterproofing membrane is necessary and which type would be most suitable for the construction.

- Q: Can a waterproofing membrane be used in areas with extreme weather conditions, such as hurricanes or snowstorms?

- Yes, a waterproofing membrane can be used in areas with extreme weather conditions, such as hurricanes or snowstorms. Waterproofing membranes are designed to provide a protective barrier against water infiltration and can effectively withstand various weather conditions. They are made from materials that are resistant to moisture and can be installed in different areas like roofs, basements, or foundations. In regions prone to hurricanes, waterproofing membranes can help prevent water damage by creating a barrier that keeps water out even during heavy rainfall or storm surges. These membranes are often reinforced and have high tensile strength to withstand the strong winds and pressure associated with hurricanes. Similarly, in areas with heavy snowstorms, waterproofing membranes can help prevent water intrusion caused by melting snow or ice dams. They are designed to be flexible and resistant to extreme temperatures, ensuring that they maintain their integrity and prevent leaks even in freezing conditions. However, it is important to choose the right type of waterproofing membrane suitable for the specific weather conditions in the area. Different membranes have varying levels of resistance to extreme weather, so it is advisable to consult with a professional to determine the most appropriate membrane for the specific climate and weather patterns. Additionally, proper installation and regular maintenance are crucial to ensure the longevity and effectiveness of the waterproofing system in extreme weather conditions.

- Q: How do waterproofing membranes prevent water leakage?

- Waterproofing membranes are designed to prevent water leakage by creating a barrier between the surface and the water. These membranes are typically made of materials such as bitumen, PVC, or EPDM, and are applied to the surface in a liquid or sheet form. The primary way in which waterproofing membranes prevent water leakage is by forming a continuous and impermeable layer. This layer acts as a physical barrier that prevents water from seeping through the surface. The membranes are applied in such a way that they cover the entire surface, including joints, cracks, and seams, ensuring that there are no areas vulnerable to water penetration. Additionally, waterproofing membranes often have excellent adhesive properties, allowing them to bond tightly to the surface. This ensures that there are no gaps or spaces where water could enter. By adhering tightly to the surface, the membranes also provide protection against the movement of water vapor, preventing moisture buildup and potential damage to the structure. Furthermore, waterproofing membranes are specifically designed to be highly resistant to water and moisture. They are made from materials that do not degrade or deteriorate when exposed to water, ensuring their longevity and effectiveness. This resistance to water also helps to prevent the membrane from becoming permeable over time. In summary, waterproofing membranes prevent water leakage by creating a continuous and impermeable barrier on the surface. They cover the entire surface, adhere tightly to prevent gaps, and are resistant to water and moisture. By implementing these measures, waterproofing membranes provide reliable protection against water infiltration and subsequent damage.

- Q: Can a waterproofing membrane be used in conjunction with soundproofing materials?

- Yes, a waterproofing membrane can be used in conjunction with soundproofing materials. In fact, it is quite common to use both of these materials together in construction projects. Waterproofing membranes are typically used to prevent the penetration of water into a structure, while soundproofing materials are used to reduce noise transmission. These two materials serve different purposes but can be used simultaneously to provide both waterproofing and soundproofing benefits. For example, in a building with a basement or a bathroom, a waterproofing membrane can be installed on the walls or floors to prevent water infiltration, and then soundproofing materials can be added on top of the membrane to reduce noise transmission from adjacent areas. By combining these two materials, a building can be protected from water damage while also providing a quieter and more comfortable environment for its occupants.

- Q: Can a waterproofing membrane be used on tunnels?

- Tunnels, being exposed to high moisture levels, groundwater infiltration, and potential leaks, necessitate the use of a waterproofing membrane. This is crucial for safeguarding their long-term structural integrity and preventing water damage. In tunnel construction, waterproofing membranes are widely employed as they effectively prevent water penetration and act as a reliable moisture barrier. These membranes are specifically designed to be durable, flexible, and resistant to different environmental conditions, making them suitable for tunnel application. By applying these membranes to the tunnel walls, roof, and floor, a waterproof seal is created, ensuring the tunnel remains dry and protected against issues such as corrosion, deterioration, and mold growth caused by water. Moreover, the use of waterproofing membranes not only helps reduce maintenance costs but also extends the lifespan of the tunnel infrastructure.

- Q: Can waterproofing membranes be used on concrete fountains?

- Concrete fountains, which are frequently subjected to water and susceptible to leaks and moisture damage, can benefit from the application of waterproofing membranes. These membranes serve as a barrier that prevents water penetration and safeguards the structure of the fountain. Designed to be flexible, durable, and resistant to water, waterproofing membranes provide an optimal solution for concrete fountains. They can be applied to both the interior and exterior surfaces of the fountain, ensuring comprehensive protection against water damage. By utilizing waterproofing membranes, the lifespan of the concrete fountain can be prolonged, and maintenance expenses can be minimized.

- Q: Can waterproofing membranes be used on concrete slabs?

- Yes, waterproofing membranes can be used on concrete slabs. These membranes are designed to provide a protective barrier against water infiltration and can effectively prevent moisture from seeping into the concrete.

- Q: Does a waterproofing membrane affect the structural integrity of a building?

- Typically, the structural integrity of a building is not affected by a waterproofing membrane. Instead, the membrane is specifically designed to safeguard the structural components of the building by preventing water infiltration and subsequent harm. Acting as a barrier against water penetration, the waterproofing membrane ensures that the building remains dry and free from moisture-related issues such as mold, rot, or deterioration. By preserving the building envelope, the membrane aids in maintaining the structural integrity of the building and prolonging its lifespan. It is crucial to note that the installation of a waterproofing membrane must be executed correctly and in accordance with industry standards to guarantee its effectiveness and prevent any potential negative impact on the structure.

- Q: Can waterproofing membranes be used on shower walls?

- Indeed, waterproofing membranes are suitable for application on shower walls. They play a crucial role in shower construction by preventing water leakage and safeguarding adjacent areas from potential harm. These membranes act as a barrier, effectively blocking water infiltration into the shower's structural components. Typically, they are installed behind the tile or other wall coverings, serving as an additional protective layer. Designed to be pliable, long-lasting, and moisture-resistant, waterproofing membranes guarantee the preservation of watertight shower walls and safeguard against any water-related harm.

Send your message to us

Top 3 EPDM Rubber Roofing Waterproof Membrane More Than 10Years

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords